Ferritic stainless steel material for brazing, and heat exchanger member

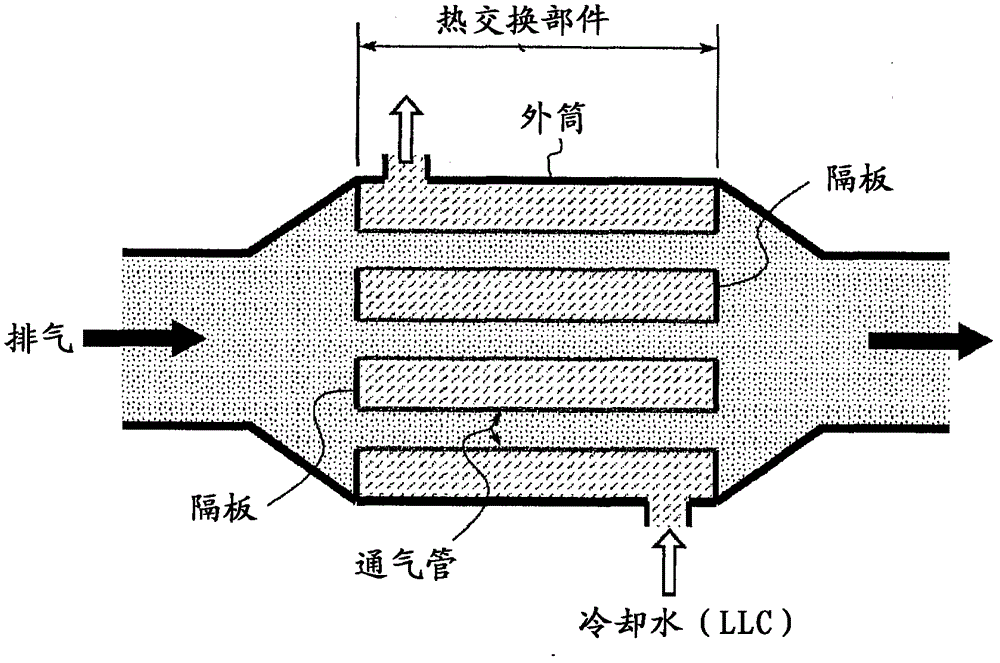

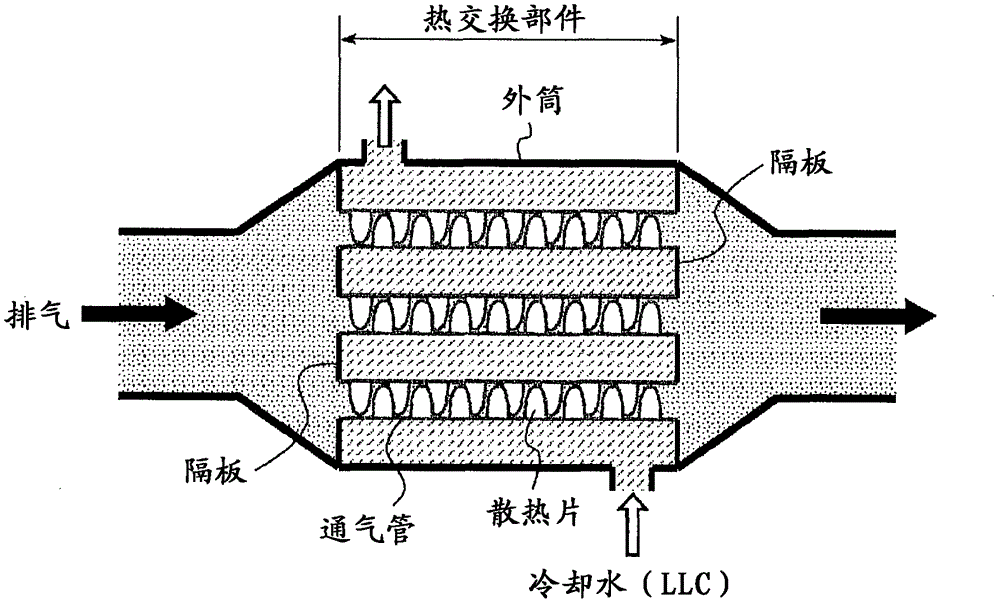

A heat exchanger, stainless steel technology, used in heat exchange equipment, heat exchangers, heat exchanger shells, etc., to achieve excellent thermal fatigue characteristics and prevent coarse graining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

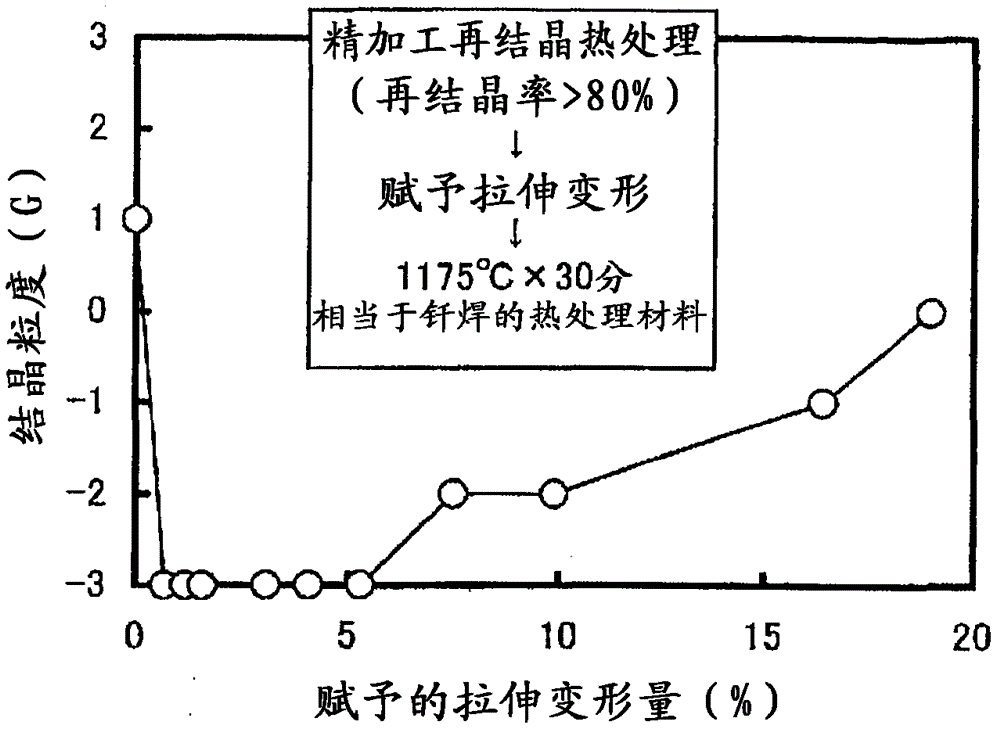

[0054] Steels having the chemical compositions shown in Table 1 were smelted, and the resulting ingots were hot-forged into round bars and plates, and processed into round bars with a diameter of 15 mm and plates with a thickness of 30 mm. The holding temperature was set in the range of 1000 to 1100° C., and solution treatment was performed on the round bar. The plate is made into a hot-rolled plate with a thickness of 4 mm by hot rolling, and after annealing treatment, it is made into a plate with a thickness of 1 mm by cold rolling. Then, the holding temperature is set in the range of 850 to 1100 ° C, and recrystallization is carried out. Heat treatment as a final anneal yields materials with various recrystallization rates. Thereafter, a part of the material was removed, and cold rolling was carried out at a light working rate (described in Table 2) at which grain coarsening tends to occur during high-temperature brazing to prepare test steel sheets. In addition, Steel No....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com