Cage nut assembly having a flexible cage

一种螺帽、组件的技术,应用在螺纹紧固件、螺钉、螺栓等方向,能够解决塑料环昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

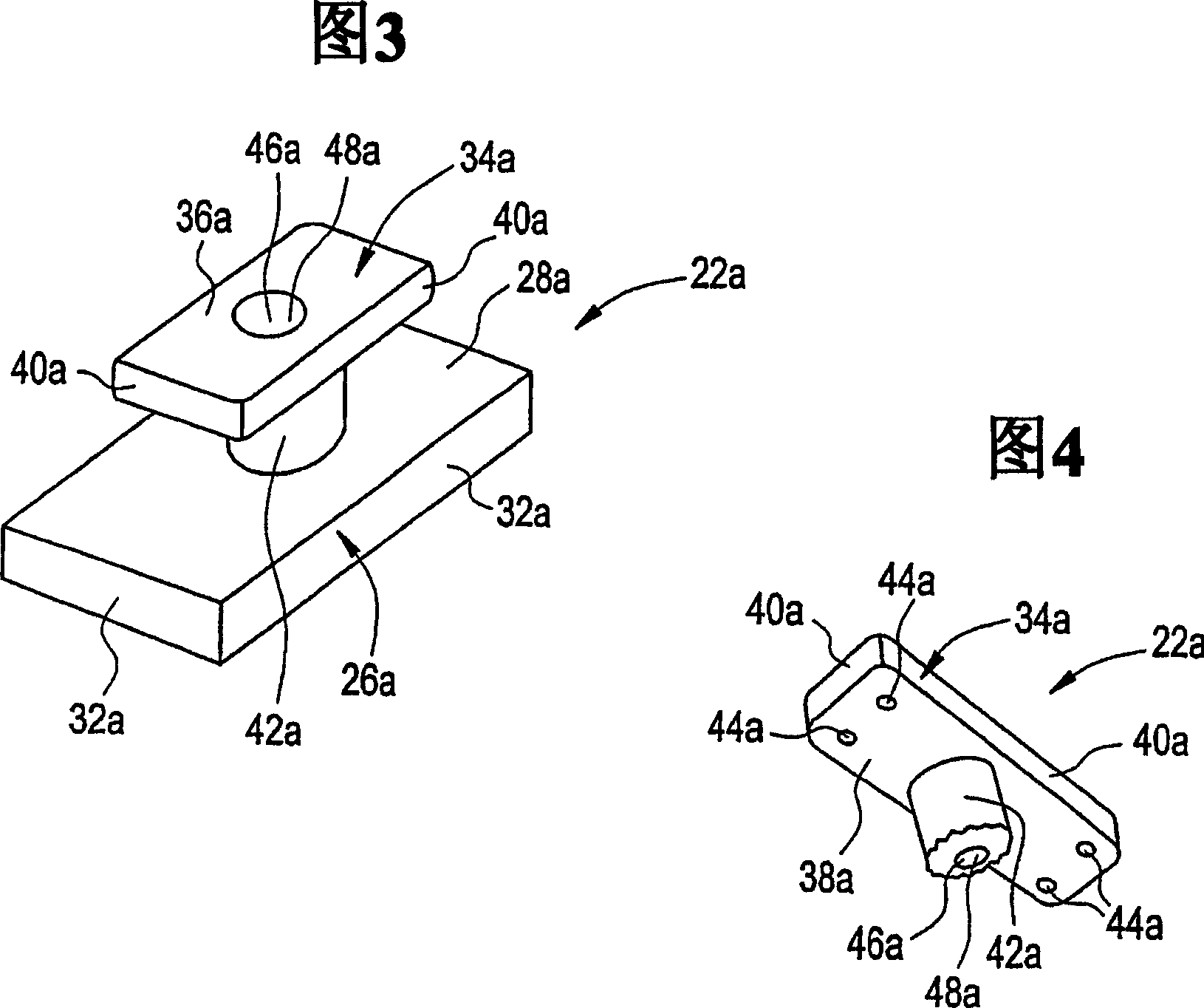

[0026] The present invention is susceptible to being embodied in different forms, which have been shown in the drawings, and specific embodiments will be described in detail here, it being clear that what is presently shown is an example of the principles of the invention and is not intended to limit the invention to the example given.

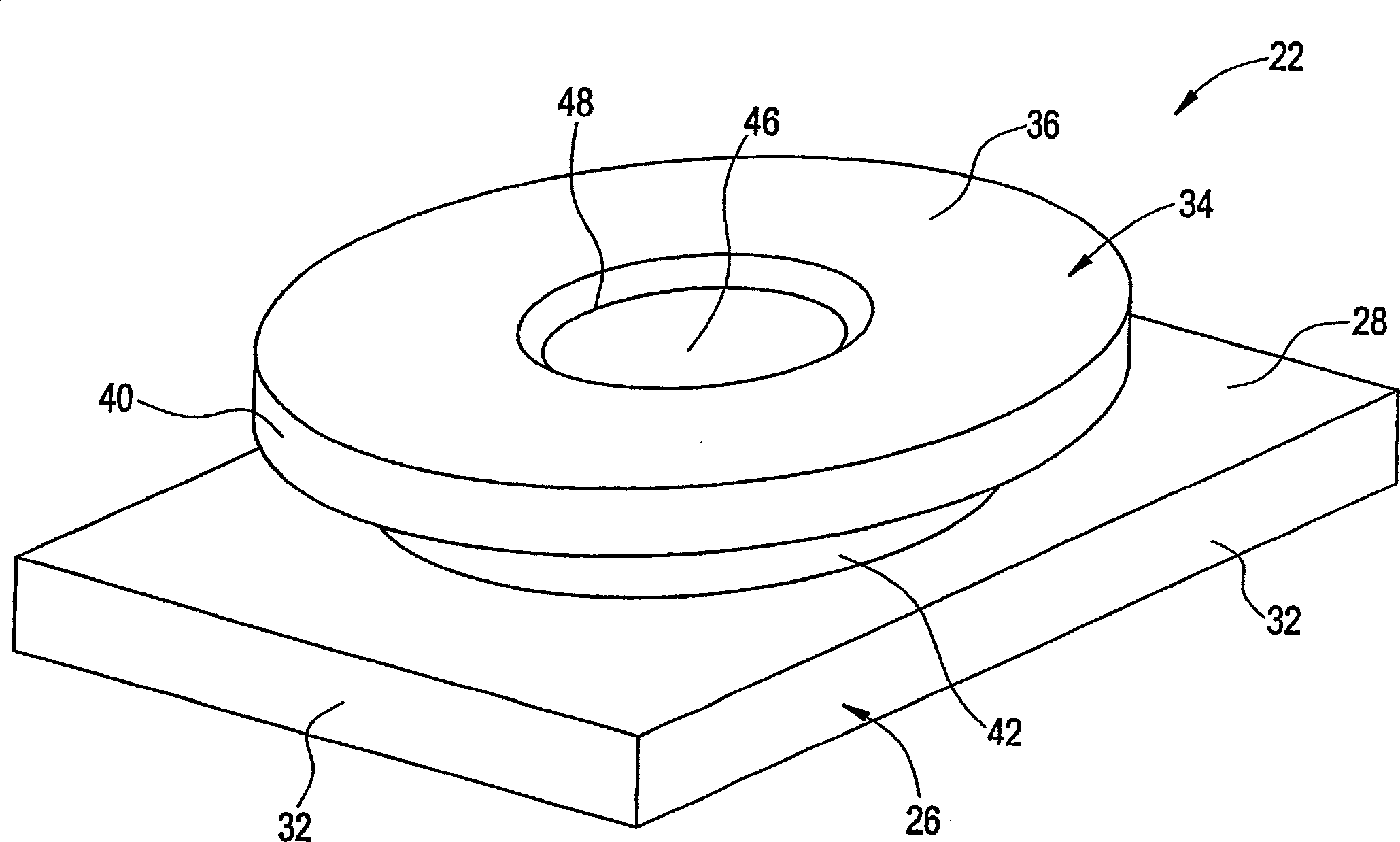

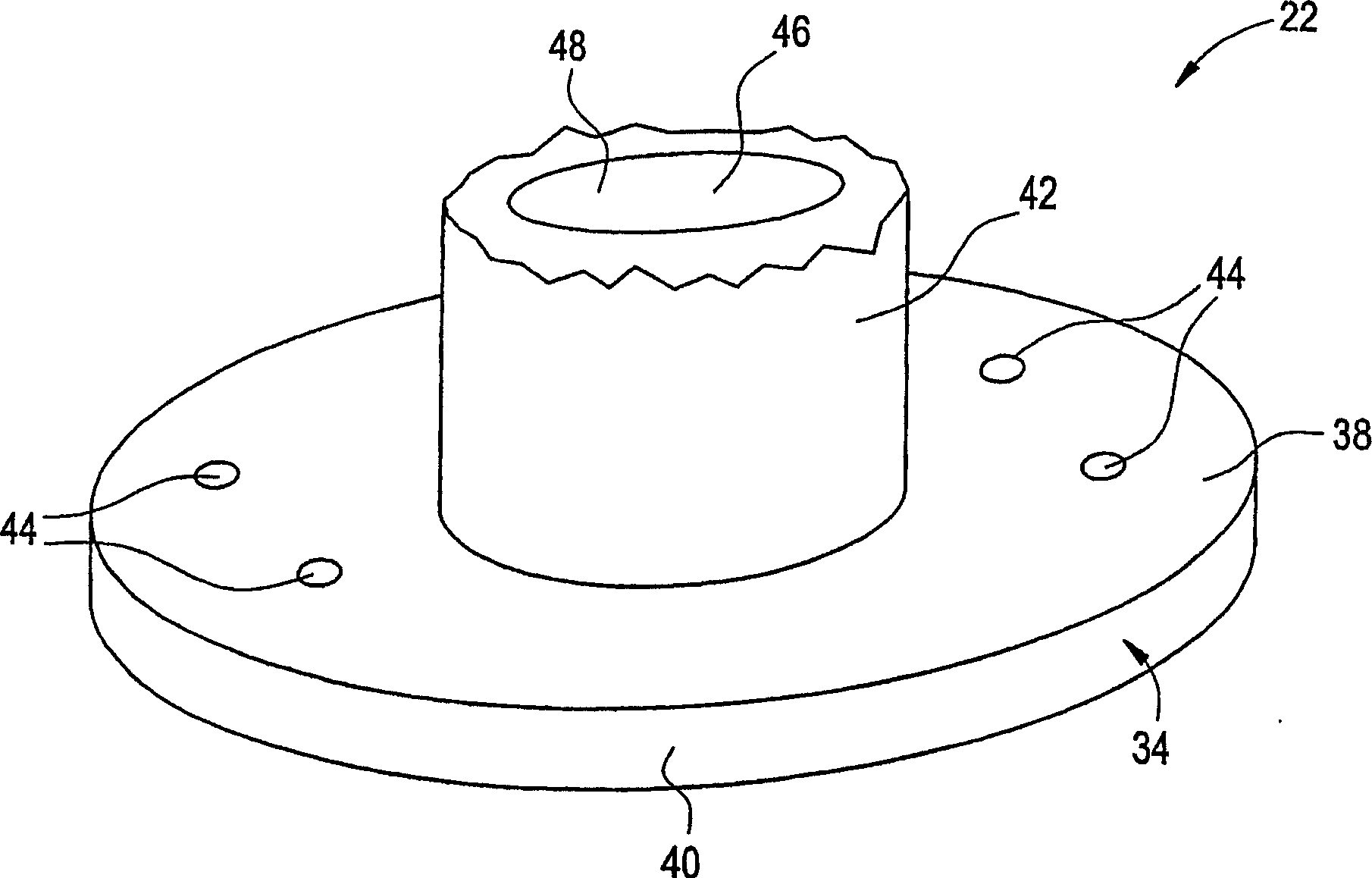

[0027] The present invention relates to a cage nut assembly 20 . The caged nut assembly 20 includes a nut 22 and a cage 24 .

[0028] Nut 22 in figure 1 with figure 2 best shown in . Nut 22 includes a preferably rectangular plate portion 26 having a generally planar upper surface 28, a generally planar lower surface (not shown), and side walls 32 connecting the upper and lower surfaces 28 and 28 together. The nut 22 also includes a preferably circular second plate portion 34 having a generally planar upper surface 36, a generally planar lower surface 38, and a side wall 40 connecting the upper surface 36 and the lower surface 38 together....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com