Recording apparatus and method

A technology of a recording device and a recording method, which is applied in the directions of typewriters, printing, and typography mechanisms, etc., can solve the problems of high production costs, high manufacturing technology, and high frequency of defective products, and achieves a high degree of image quality improvement. The effect of reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

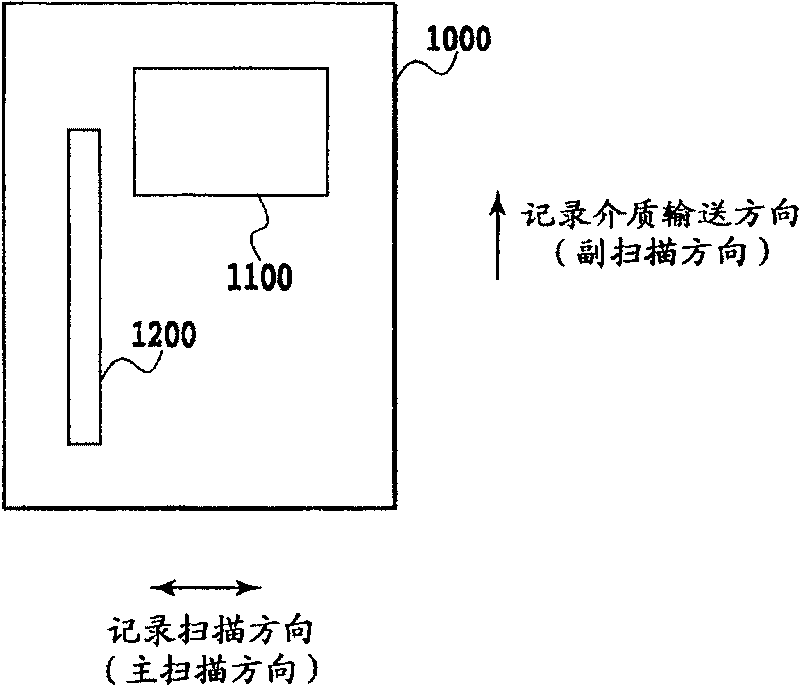

[0148] An example of a recording head in which a 1-color 4-column structure is set for cyan and magenta and a 1-color 2-column structure is set for the remaining colors will be described.

[0149] Figure 10 It is a schematic diagram showing the arrangement of discharge ports for each color ink in the color ink unit 1100 .

[0150] The color ink recording unit of the present invention is provided with a plurality of discharge ports and heaters for generating heat used to discharge ink from the respective discharge ports for the inks of cyan, magenta, and yellow and the second black ink. Wait. Also, two discharge port rows are provided for each color ink. The configuration of the two discharge port rows is symmetrical as above for the cyan, magenta, and yellow inks. For the second black ink, such a configuration is not adopted, and it is set at the discharge port of the yellow ink. Between the row y2 and the row m2 of discharge ports for magenta ink, the discharge port rows ...

Embodiment 2

[0195] In Example 1 ( Figure 10 ) in the recording head structure, the nozzles of the nozzle rows c3, c4, m3, and m4 are set as small-diameter nozzles forming small dots, but the present invention can be realized even with large-diameter nozzles forming large dots.

[0196] Figure 17 An example of a recording head in which the nozzle diameter is set to be the same regardless of the nozzle row is shown.

[0197] exist Figure 17 , a detailed nozzle column description with Figure 10 are roughly the same and are therefore omitted.

[0198] Here, as also described in Embodiment 1, it is explained that it is desirable to arrange nozzles with a displacement of 1 / 4 of the nozzle pitch between the nozzle row groups c1, c2 and the nozzle row groups c3, c4. Figure 10 or Figure 17 The adjacent nozzle columns c1 and c3, or c2 and c4 are arranged with a 1 / 4 nozzle pitch offset. The effect of satisfying this relationship between adjacent nozzle rows will be specifically described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com