Mold lapping-in paper and mold lapping-in method

A mold and pulp technology, which is applied in special paper, synthetic cellulose/non-cellulose material pulp/paper, paper, etc., can solve the problems of high operator operation level and high research and development costs, so as to reduce research and development costs , to reduce the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the mold grinding paper of the present disclosure may be a conventional method in the art, and will not be repeated here.

[0033] The second aspect of the present disclosure provides a method for mold grinding using the mold grinding paper described in any one of the first aspect, the method includes the following steps: (1) placing the mold grinding paper under the mold (2) after mold closing, take off the mold lapping paper, and lap the high point of the mold gap.

[0034] The above-mentioned mold grinding method provided by the present disclosure uses paper for mold grinding instead of metal stamping parts, reduces the use of metal stamping parts, and reduces grinding costs; moreover, there is no need to paint red lead on the surface of the mold grinding paper during the grinding process Powder or blue lead powder, to avoid uneven application of red lead powder or blue lead powder and affect the effect of mold grinding.

[0035] Preferably...

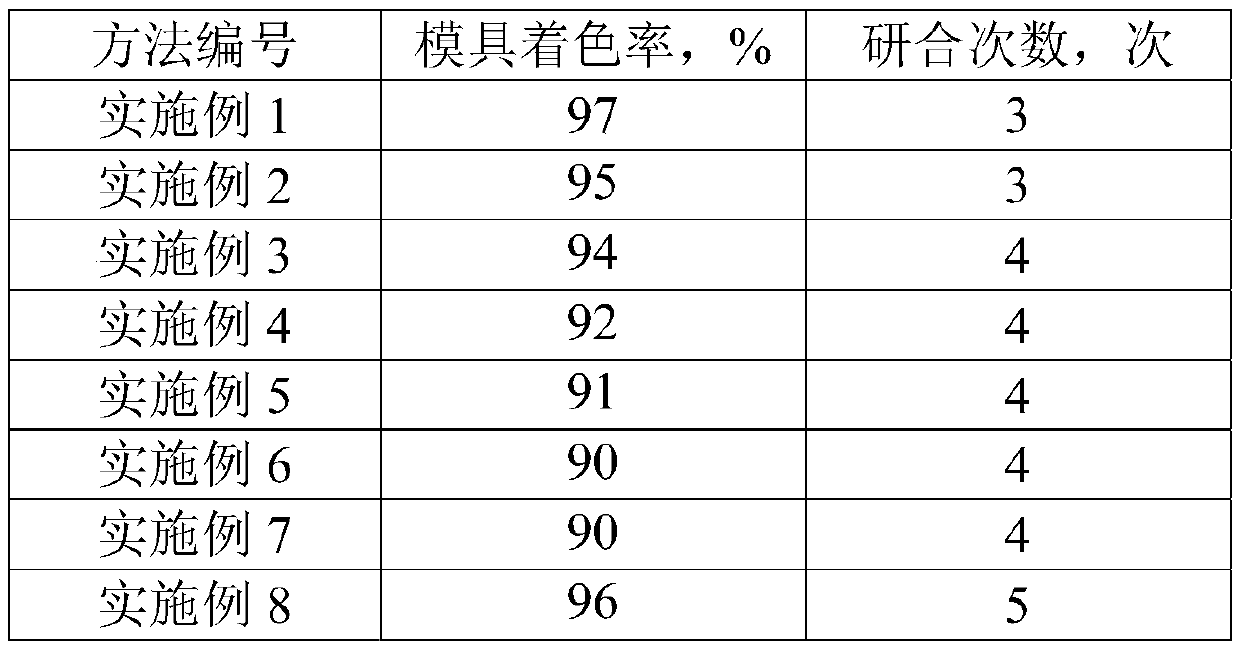

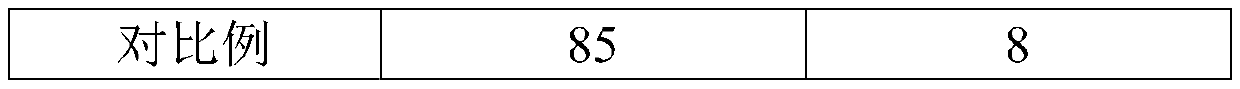

Embodiment 1

[0039] According to the needs of mold grinding, cut the paper for mold grinding into rectangles, squares, and trapezoids of any size within the range of 4m, and then lay it flat on the lower mold of the mold, so that the upper mold and the lower mold of the mold can be closed. After the end, remove the mold grinding paper, and grind the high point of the mold gap.

[0040] In the present embodiment, the toughening fiber (polyester fiber) of 40% by weight is contained in the paper for mold lapping, the paper pulp (wood pulp) of 40% by weight, the tackifier (by polypropylene, vegetable oil) of 18% by weight , polyvinyl acetate and wax are mixed according to the weight ratio of 5:5:3:5) and 2% by weight of pigment (red lead powder).

Embodiment 2

[0042]Utilize the method for embodiment 1 to carry out mold grinding, the difference is: in the present embodiment, the toughening fiber of 35% by weight is contained in the mold grinding and combining paper, the paper pulp of 40% by weight, the viscosifying of 20% by weight agent and 5% by weight of the pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com