Cooking fume guiding machine

A technology of oil fume and guide wall, which is applied in the direction of oil fume removal, household heating, lighting and heating equipment, etc. It can solve the problems of difficult cleaning, many use failures, and non-adjustable wind direction, etc., and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

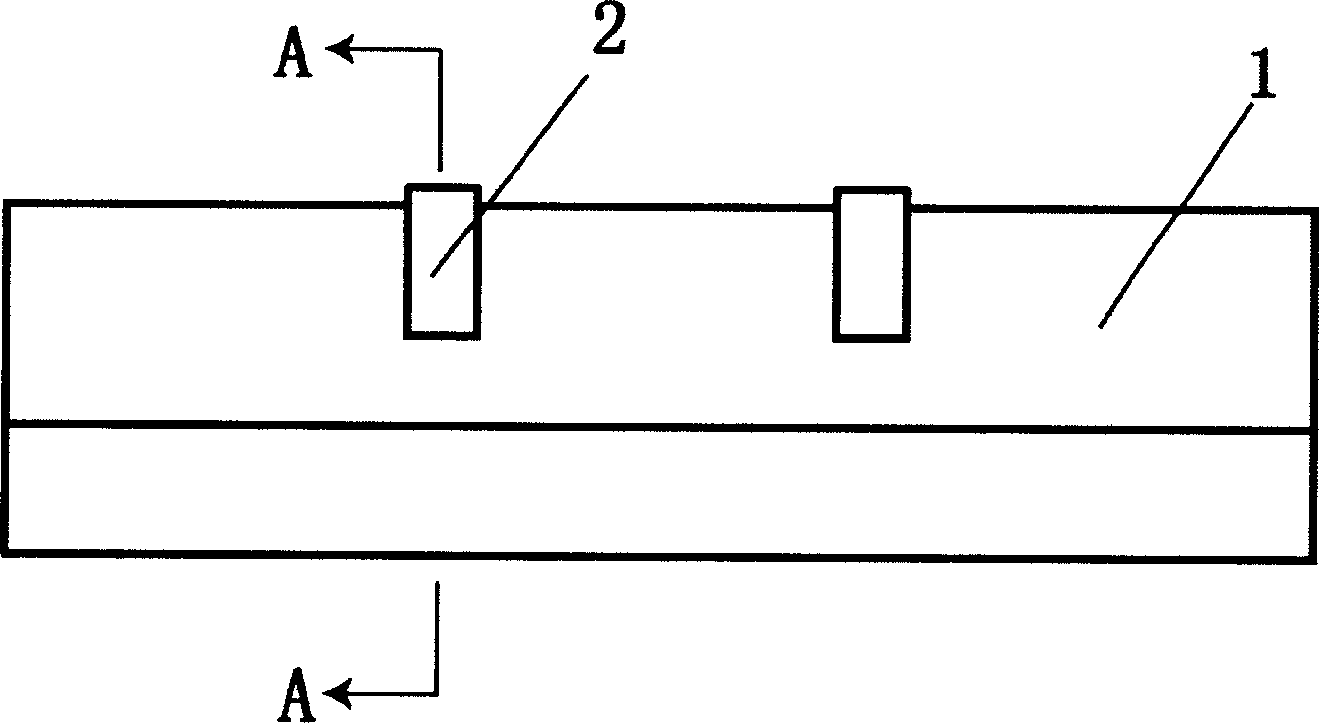

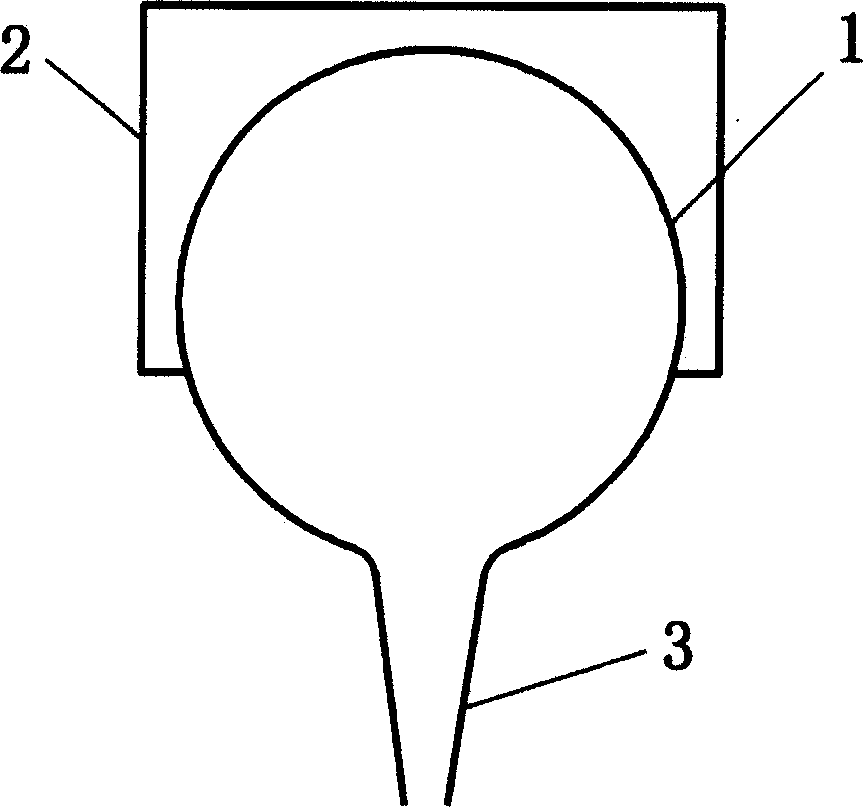

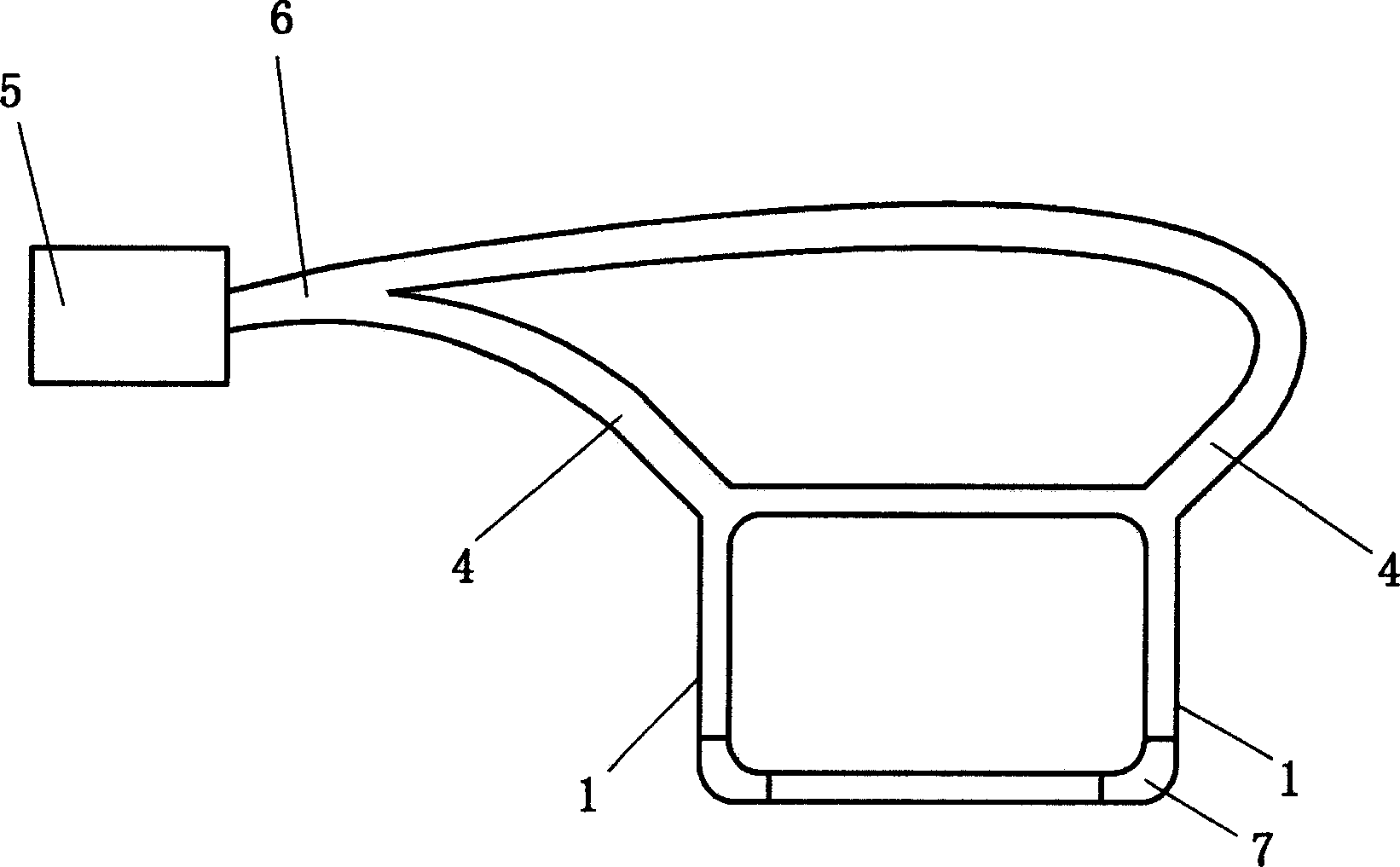

[0032] A lampblack deflector, comprising an air supply device, an air curtain forming device, and a pipeline or an air duct connecting the air supply device and the air curtain forming device. This structural design improves the safety of the entire device and facilitates disassembly and cleaning; The air curtain forming device includes an air duct or an air channel installed on the range hood to form an air curtain, the air duct or air duct forming the air curtain is provided with an air outlet, and an air curtain forming guide wall ( Arm), under the action of the air supply device, an air curtain can be formed through the air duct or air duct to prevent the oil fume from escaping. The air pipe forming the air curtain is covered with a fixing piece, and the fixing piece and the air pipe forming the air curtain are connected by rotation. By r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com