Refrigeration air dryer

a technology of refrigerating air dryer and air pipe, which is applied in the direction of defrosting, separation process, and domestic cooling apparatus, etc., can solve the problems of condensation water leading to a puddle on the floor, condensation water can decay, and the performance of the reheater can drop depending upon, so as to achieve high dehumidification performance and effectively use energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

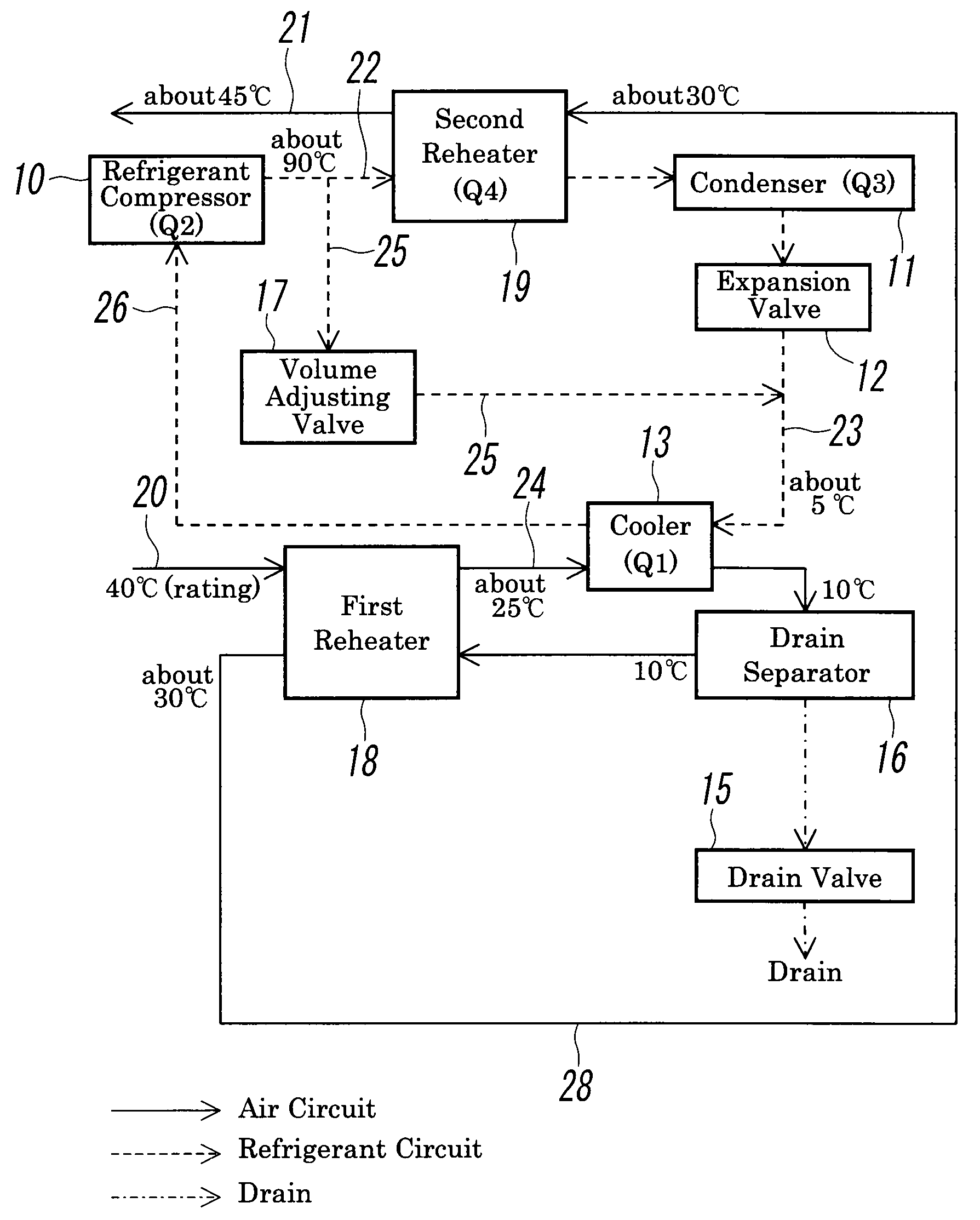

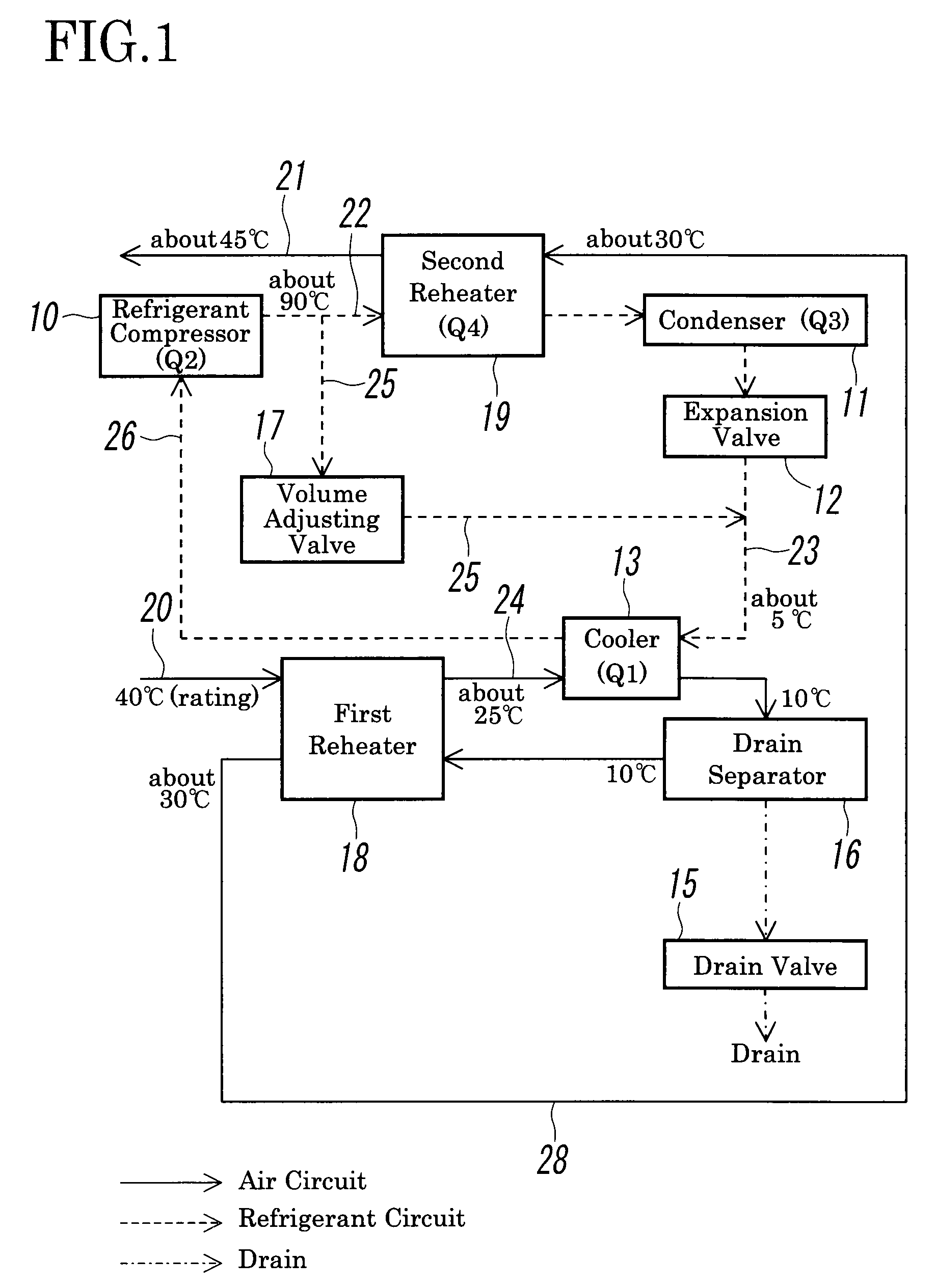

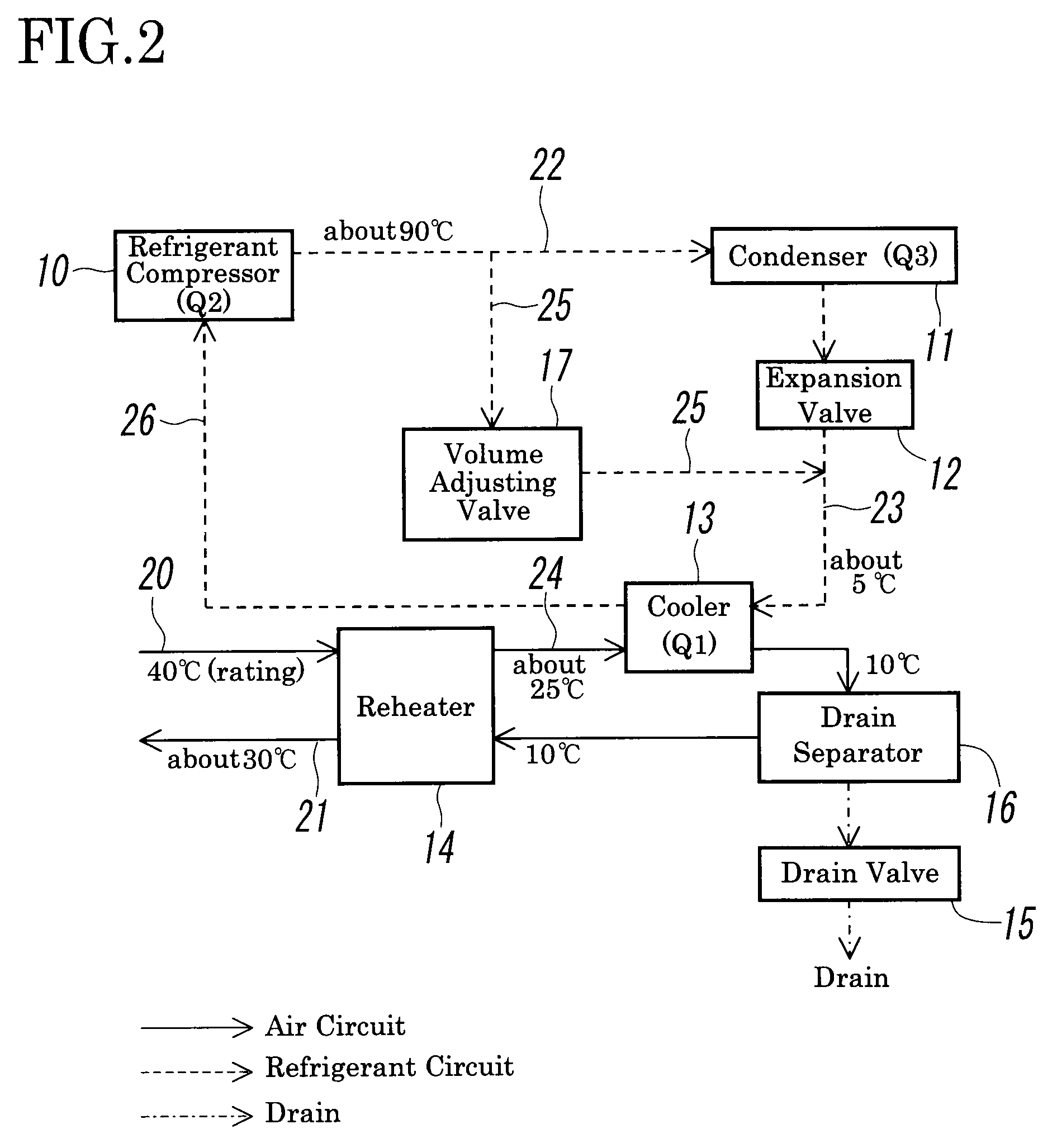

[0028]FIG. 1 shows an embodiment of a refrigeration air dryer according to the present invention. The refrigeration air dryer according to the embodiment includes a refrigerant system and an air system in which several components are the same as those in the conventional refrigeration air dryer shown in FIG. 2. Accordingly, in FIG. 1, the same components as those in FIG. 2 are denoted by the same reference numerals. The major difference between the embodiment and the conventional refrigeration air dryer shown in FIG. 2 is that the embodiment employs a first reheater 18 and a second reheater 19 in order to reduce electric power consumption while maintaining the stable operation of the refrigeration air dryer.

[0029]The refrigerant system in the refrigeration air dryer shown in FIG. 1 includes a refrigerant compressor 10, a condenser 11 which condenses a high-temperature refrigerant which has been compressed by the refrigerant compressor 10 and has been transmitted from a high-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com