Implant for fixing bones

An implant and fixation technology, applied in the field of implants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

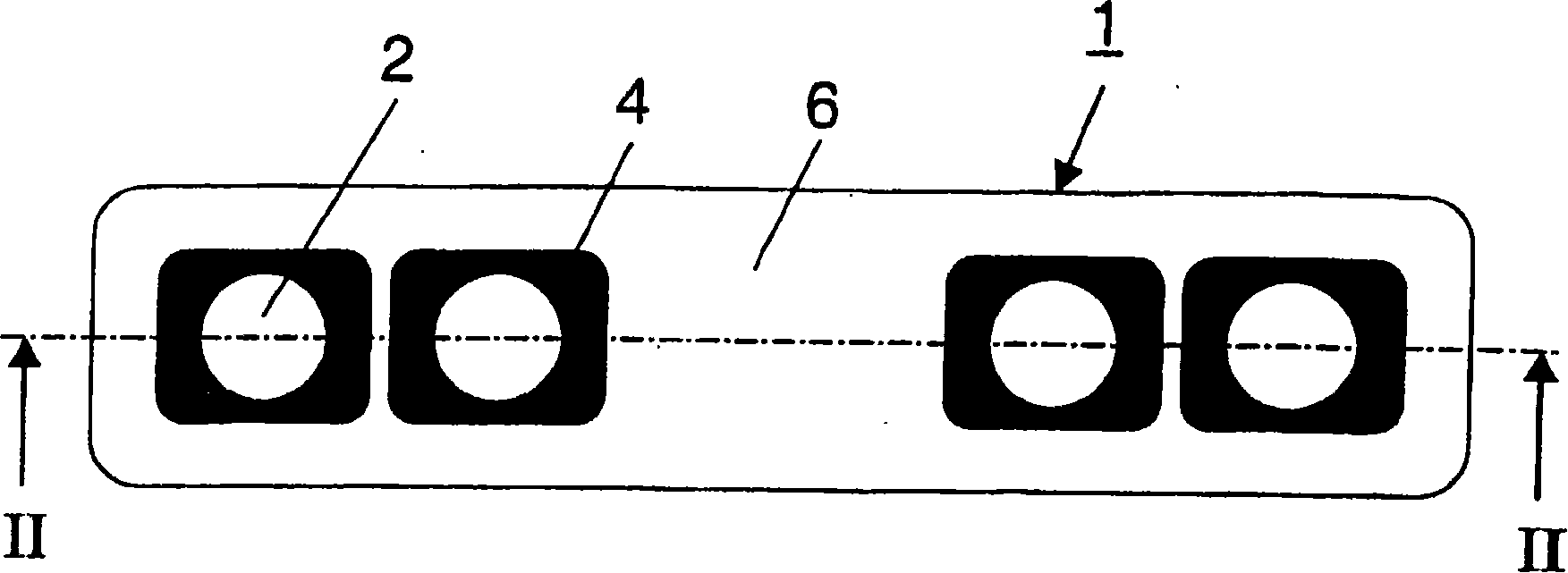

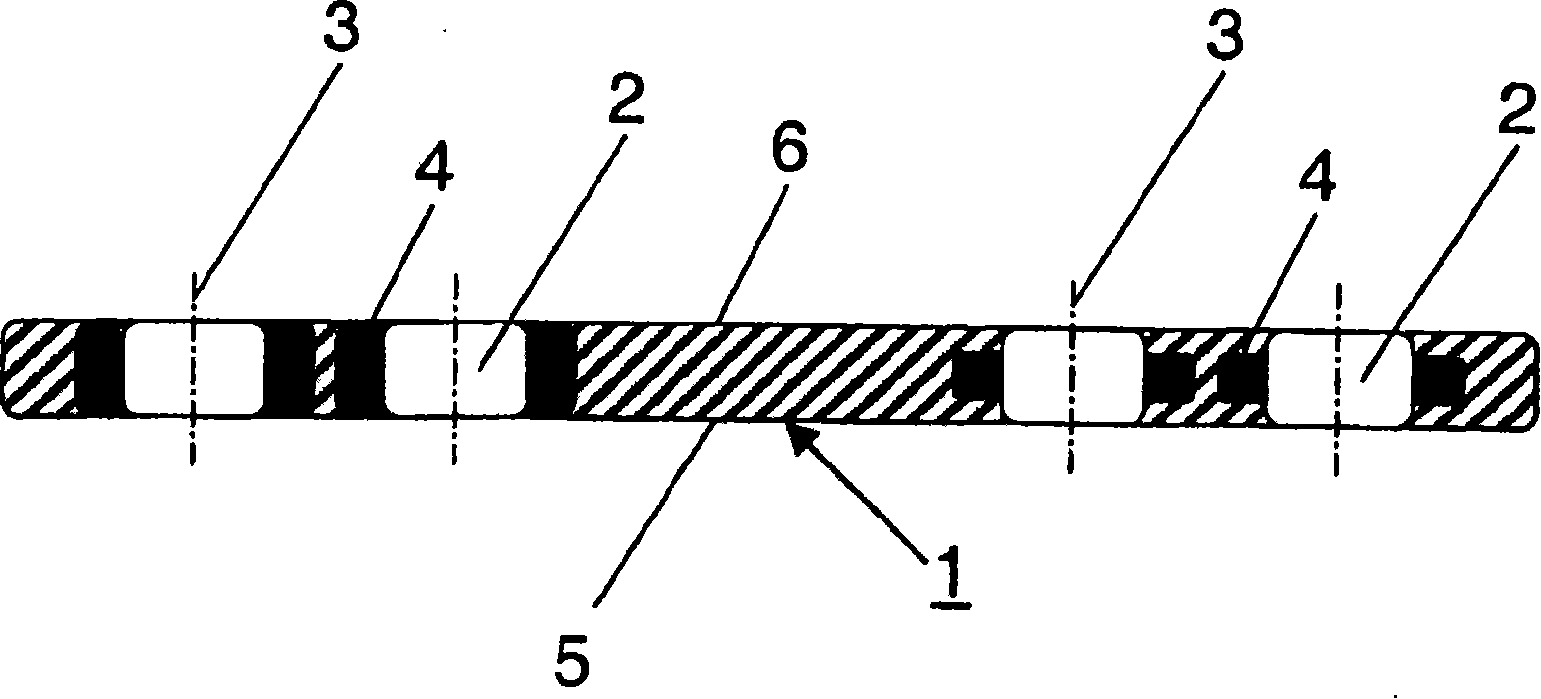

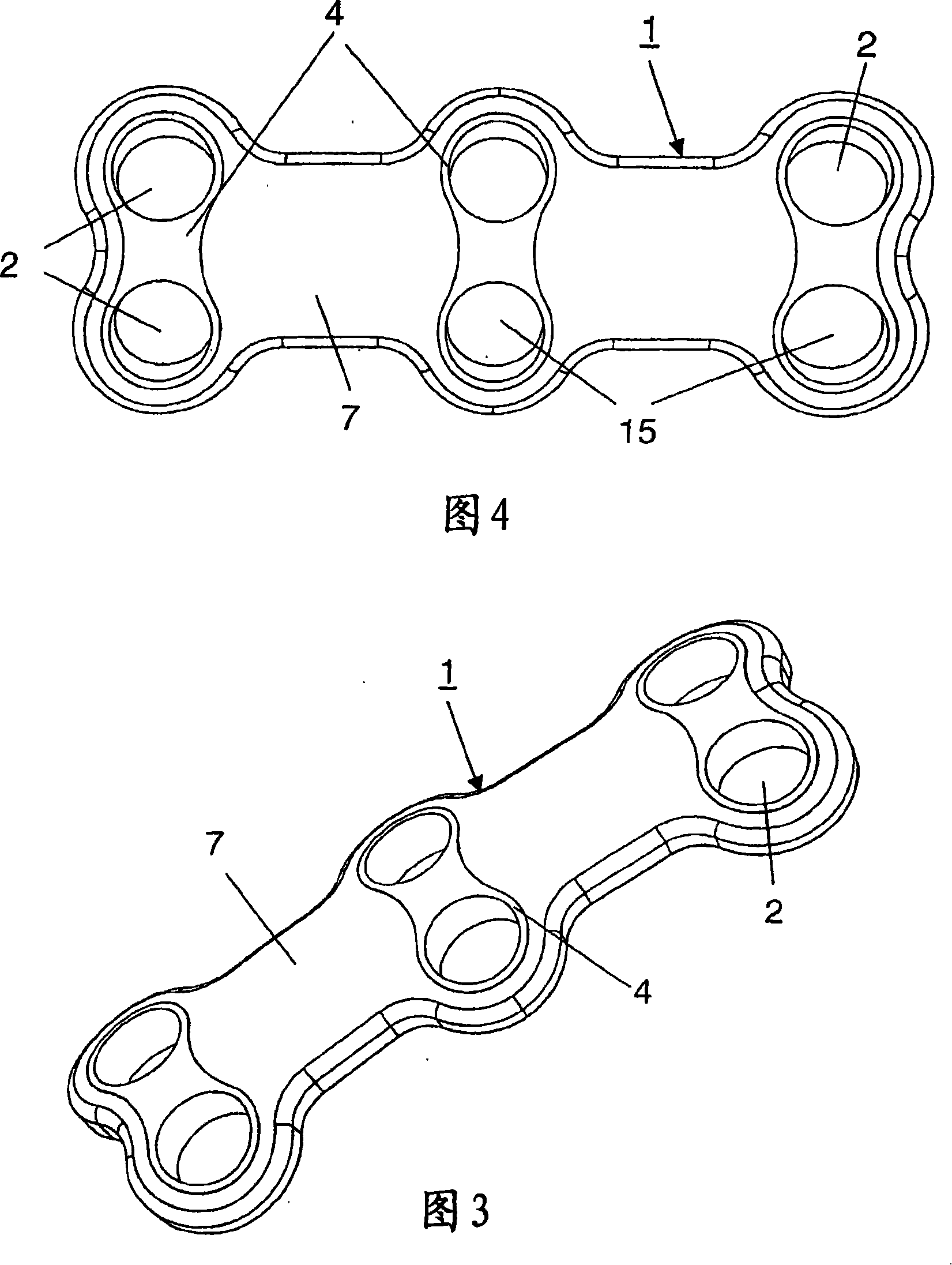

[0028] in figure 1 with figure 2 The implant 1 shown in is a bone plate, which is basically composed of a biocompatible plastic such as polyetheretherketone (PEEK) and has four circular holes in the form of channels 2 with axis 3 for Accommodate bone screws (not shown in the figure). The channel 2 connects the bottom surface 5 of the bone plate for abutting on the bone and the top surface 6 thereof.

[0029] In this case, the channel 2 is embedded in the form of some rectangular metal small plates, which can be understood as the outer envelope part 4 of the channel 2. For example, the outer envelope part 4 made of titanium can be embedded in the surrounding plastic material 7 (for example, PEEK) in a form-locking manner and fixedly connected with the plastic material 7 by injection molding according to its manufacturing method.

[0030] A variation of the outer envelope part 4 embedded in the plastic material 7 is shown in figure 2 On the right, in this form, the height of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com