Cationic black dyes for modified terylene dyeing

A black dye, cationic technology, applied in the field of modified polyester and polyester one-bath dyeing, can solve the problem that cationic dyes are not resistant to high temperature and high pressure, and achieve the effect of bright color, excellent fastness and constant brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

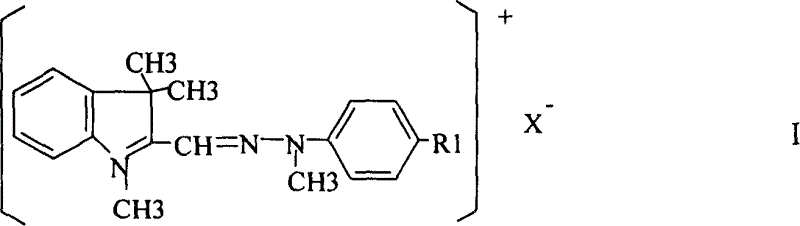

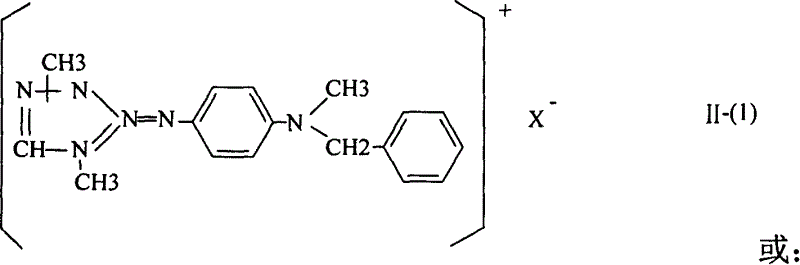

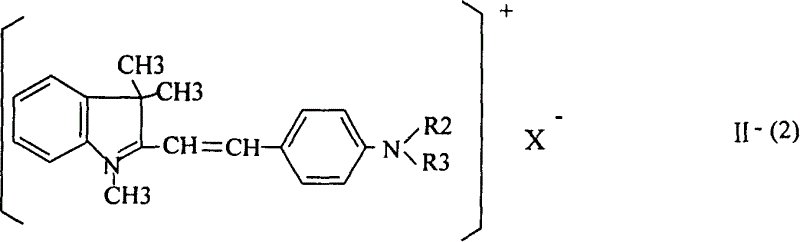

Method used

Image

Examples

example 1~10

[0034] According to the data shown in Table 1, add yellow dye, red dye, blue dye, and diffusing agent NNO into the mixer, and mix for 4 to 8 hours to obtain cationic black dye for modified polyester dyeing.

[0035] The yellow dye can be selected from the golden SD-GL and yellow SD-5GL produced by Zhejiang Runtu Co., Ltd., Shanghai Qingcheng Dyestuff Chemical Co., Ltd., Shanghai Jiaye Dyestuff Chemical Co., Ltd., and the yellow SD-GRL produced by Zhejiang Runtu Co., Ltd. . The red dye can be selected from the red SD-GRL and bright red SD-5GN produced by Zhejiang Runtu Co., Ltd., Shanghai Qingcheng Dyestuff Chemical Co., Ltd., Shanghai Jiaye Dyestuff Chemical Co., Ltd., and the red SD-5GN produced by Zhejiang Runtu Co., Ltd. 2BL. The blue dyes can be blue SD-GSL and blue SD-BL produced by Zhejiang Runtu Co., Ltd., Shanghai Qingcheng Dyestuff Chemical Co., Ltd., Shanghai Jiaye Dyestuff Chemical Co., Ltd., and blue SD-BL produced by Zhejiang Runtu Co., Ltd. 4GSL, Lan SD-F2RL. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com