Structure of forming pressure contact with power semiconductor module

A technology of power semiconductor and connection structure, applied in the direction of semiconductor device, printed circuit structure connection, semiconductor/solid-state device components, etc., can solve the problem of not guaranteeing the reliability of welding connection and contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

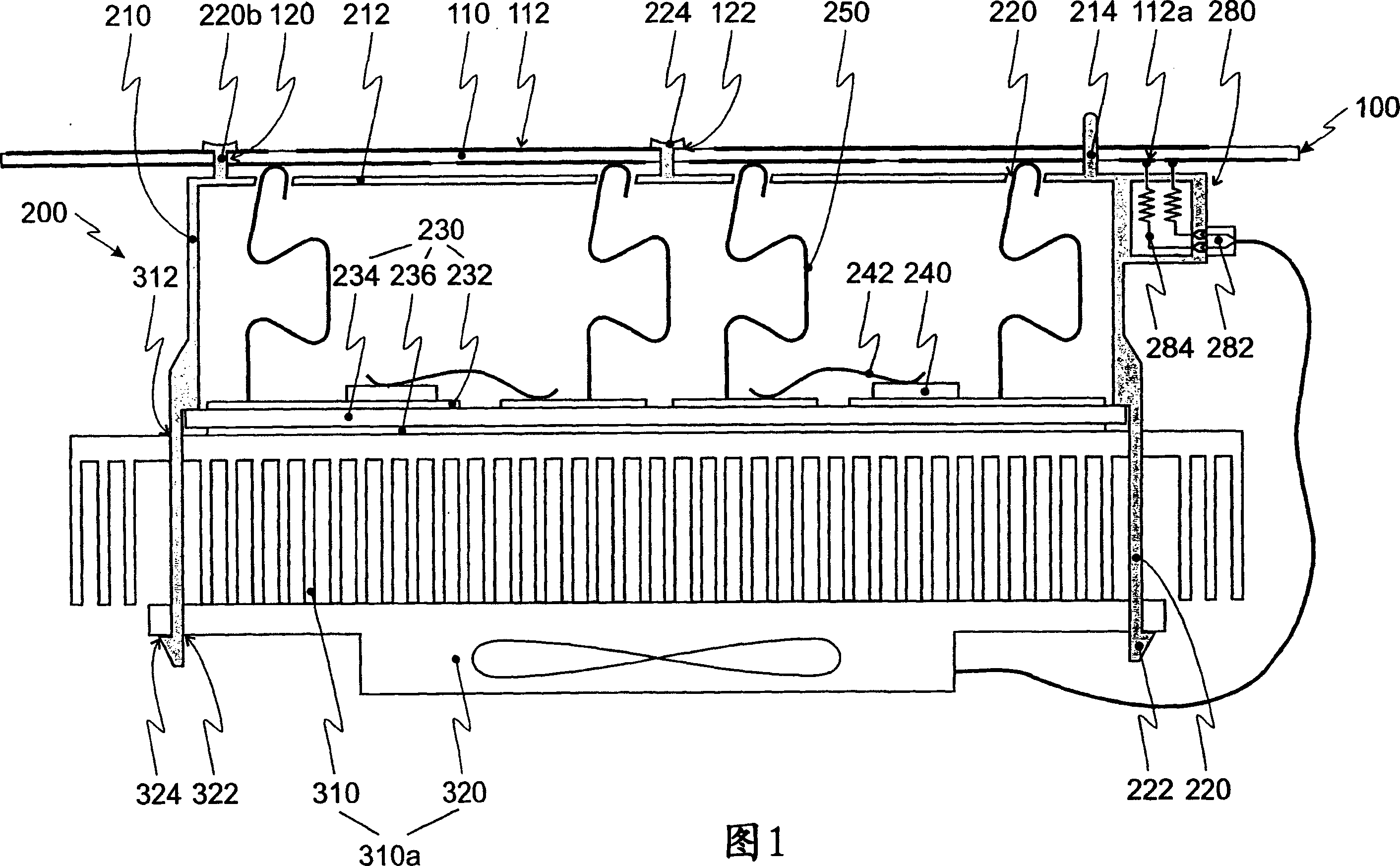

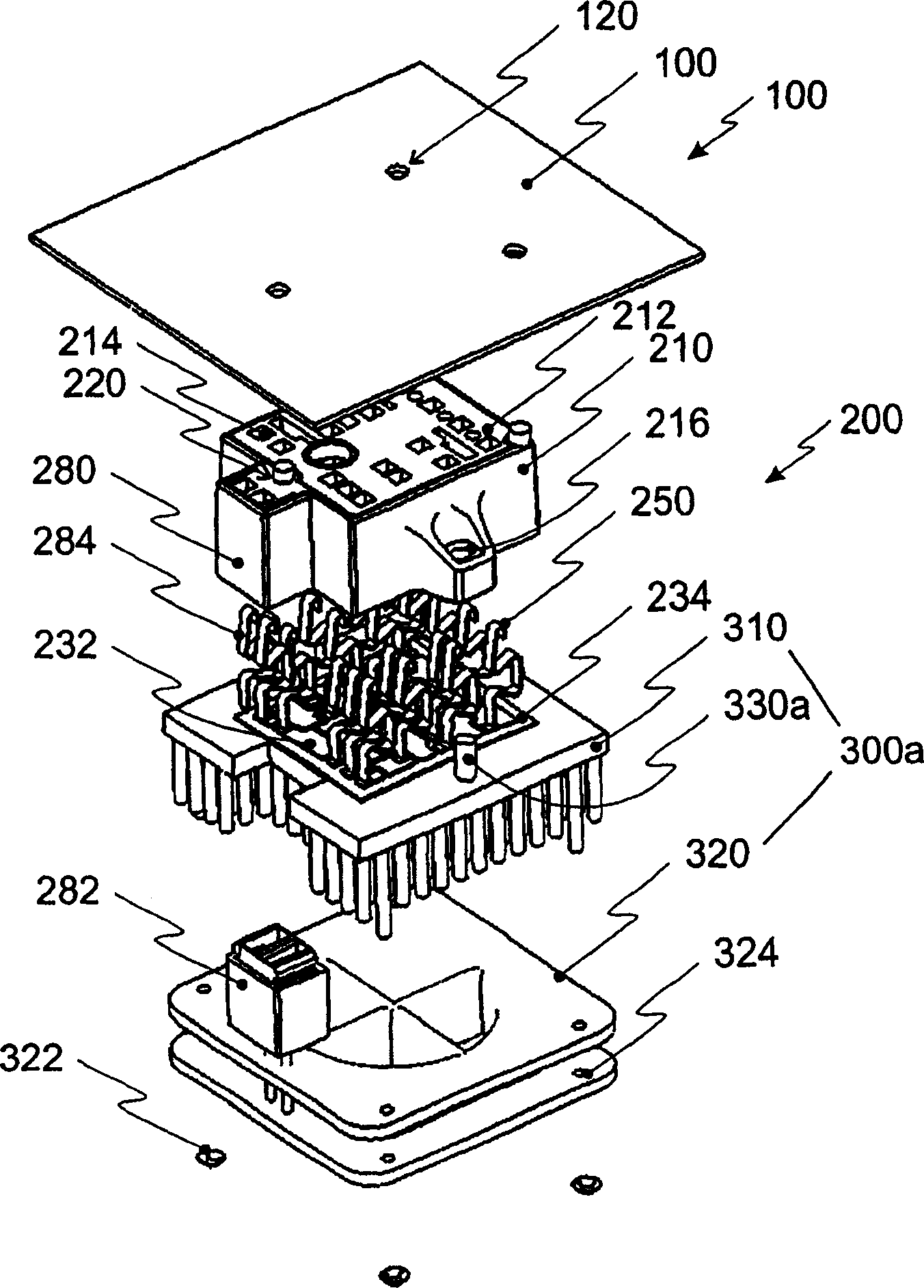

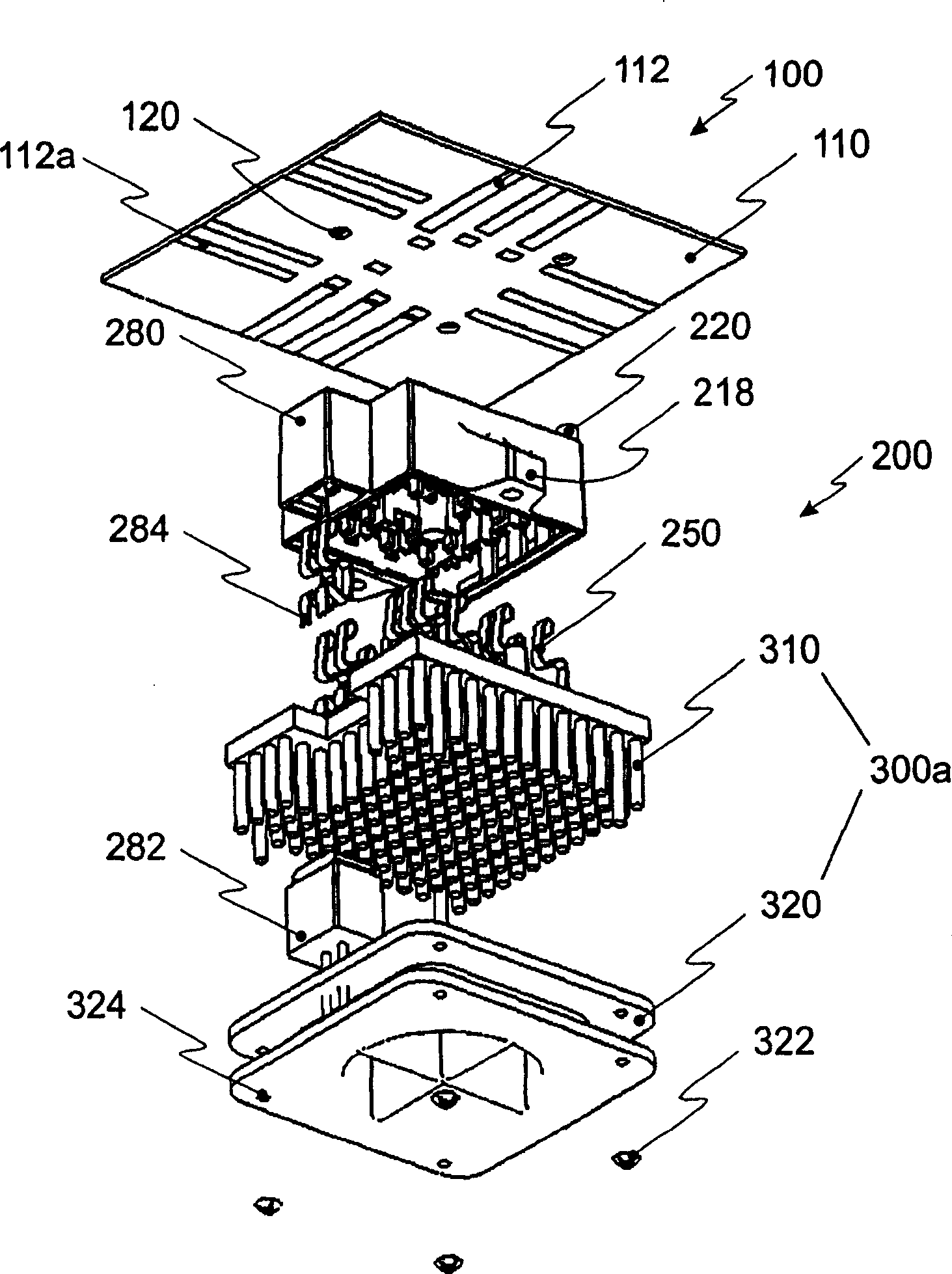

[0025] Figure 1 shows a cross-section of the structure of the present invention. The structure shown consists of a circuit board 100 , a power semiconductor module 200 and a cooling device 300 .

[0026] The circuit board 100 has an insulator 110, and conductive strips 112 arranged on and / or within the insulator. These busbars carry signals such as load signals, control signals and auxiliary signals of the power semiconductor module 200 .

[0027] The power semiconductor module 200 has a frame-like housing 210 with an integrated cover 212 . The second cover of the housing 210 is constituted by the base plate 230 . The substrate consists of an insulator 234, preferably a technical ceramic such as aluminum oxide or aluminum nitrite, and metal layers 232, 236 on both sides of the insulator. Here the metal layer is applied on the insulator 234 by means of the known DCB method. Preferably, the metal layer 232 towards the interior of the housing is structured to form mutually in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com