Thrust surface friction diminishing device for vane type compressor

A friction-reducing, vane-type technology used in parts of pumping devices for elastic fluids, rotary-piston/oscillating-piston pump parts, machinery, etc. to address performance degradation, oil shortage, compressor pressure problems such as rise, to achieve the effect of improving performance, improving reliability, and preventing pressure rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

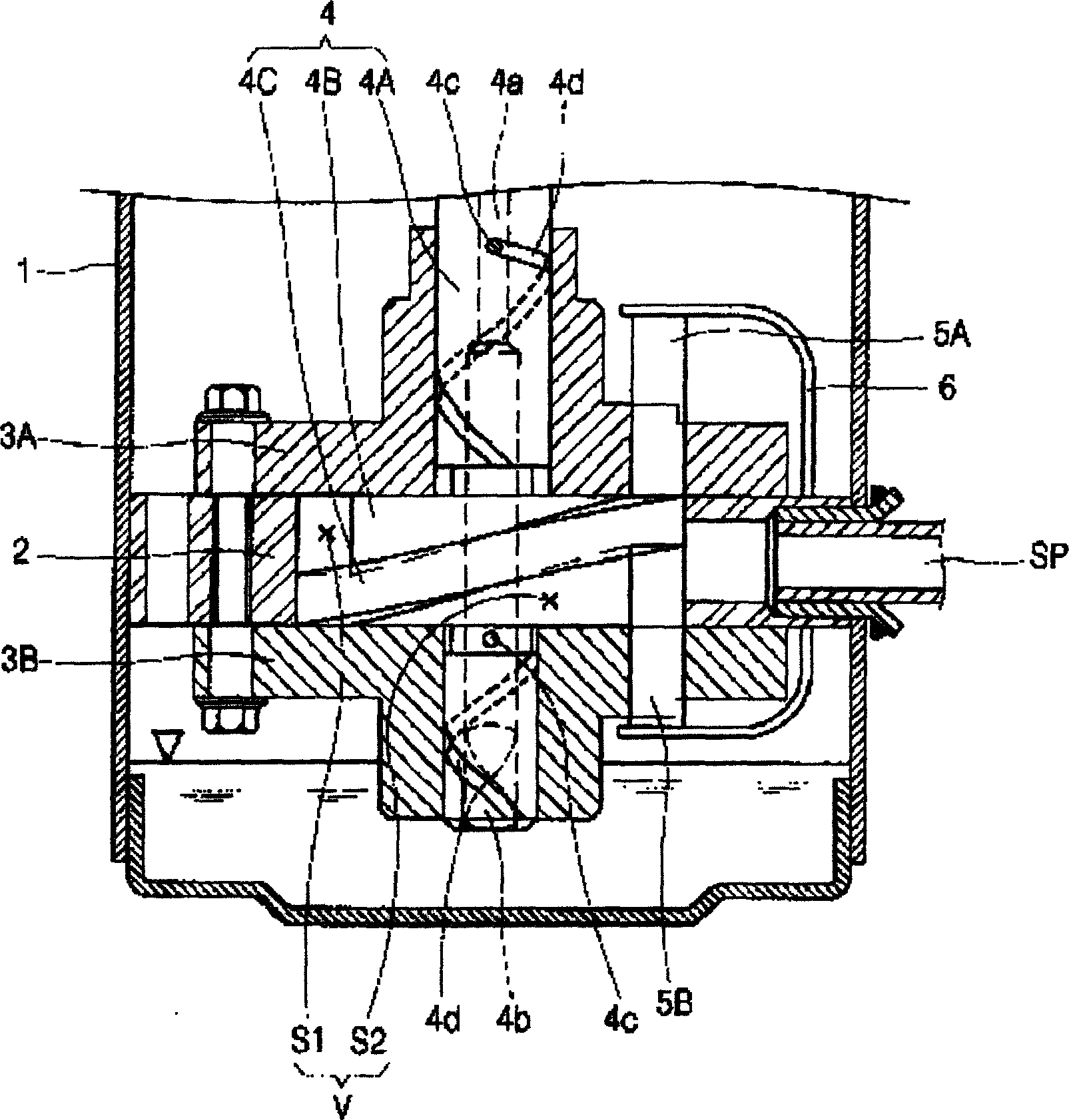

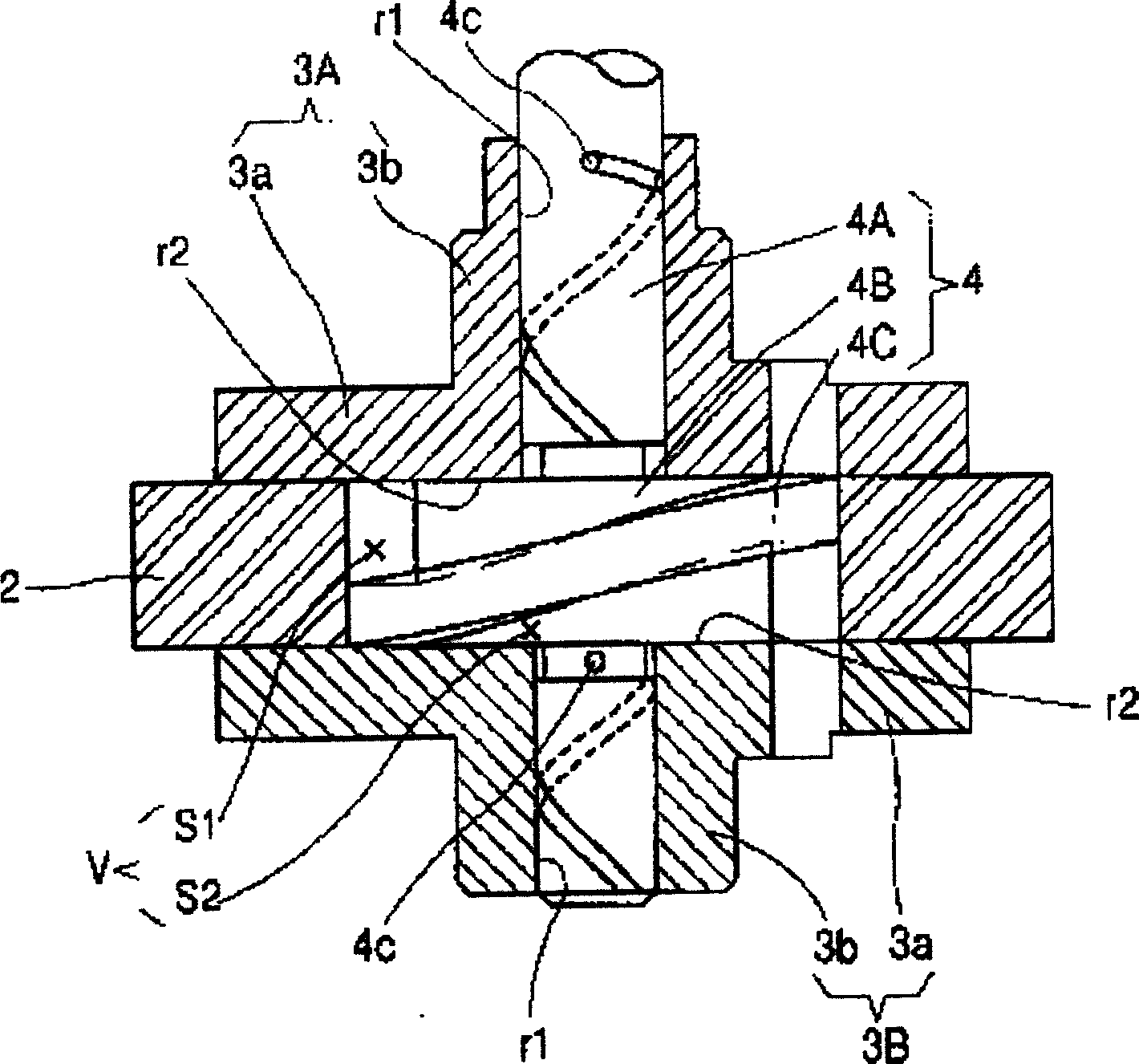

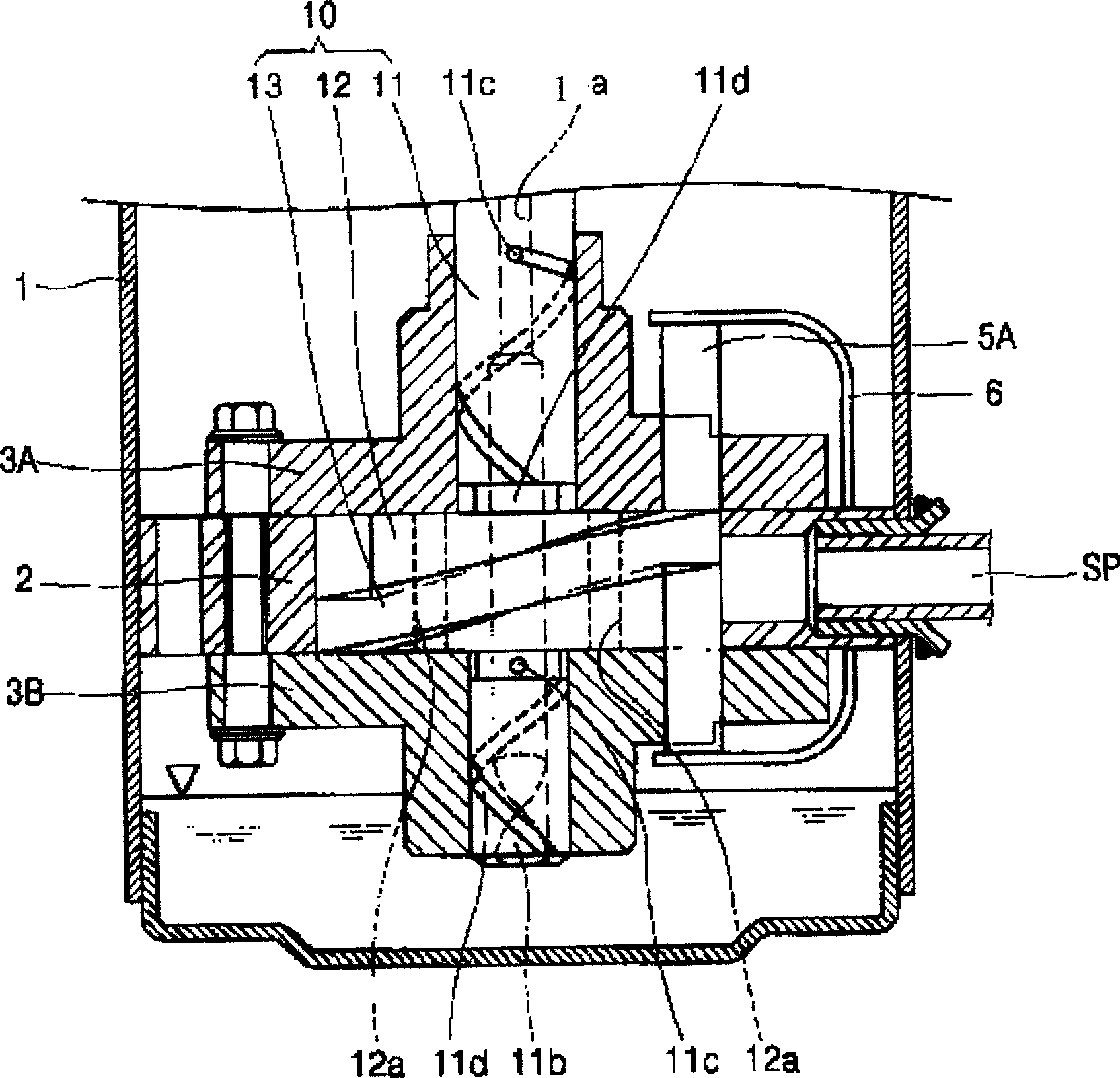

[0039] The thrust surface friction reduction device of the vane compressor of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

[0040] Such as Figure 3 to Figure 5 As shown, the compression mechanism of the vane compressor of the present invention includes a cylinder 2, a first bearing plate 3A and a second bearing plate 3B, a first bearing plate 3A and a second bearing plate 3B, a rotating shaft 10, and a first blade 5A. And the second blade 5B, blade spring 6, the cylinder 2 includes the internal space V for sucking compressed refrigerant gas, and is fixed on the lower half of the shell 1, and the first bearing plate 3A and the second bearing plate 3B are respectively installed on the cylinder 2 and the bottom, together form the cylinder assembly, the rotating shaft 10 divides the internal space V of the cylinder assembly into a plurality of closed spaces, the rotating shaft 10 also includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com