Punching apparatus

A punching device and punching die technology, applied in the field of punching device, can solve problems such as difficulty, raw material rupture, cost increase, etc., and achieve the effects of suppressing excessive inflow, preventing rupture, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

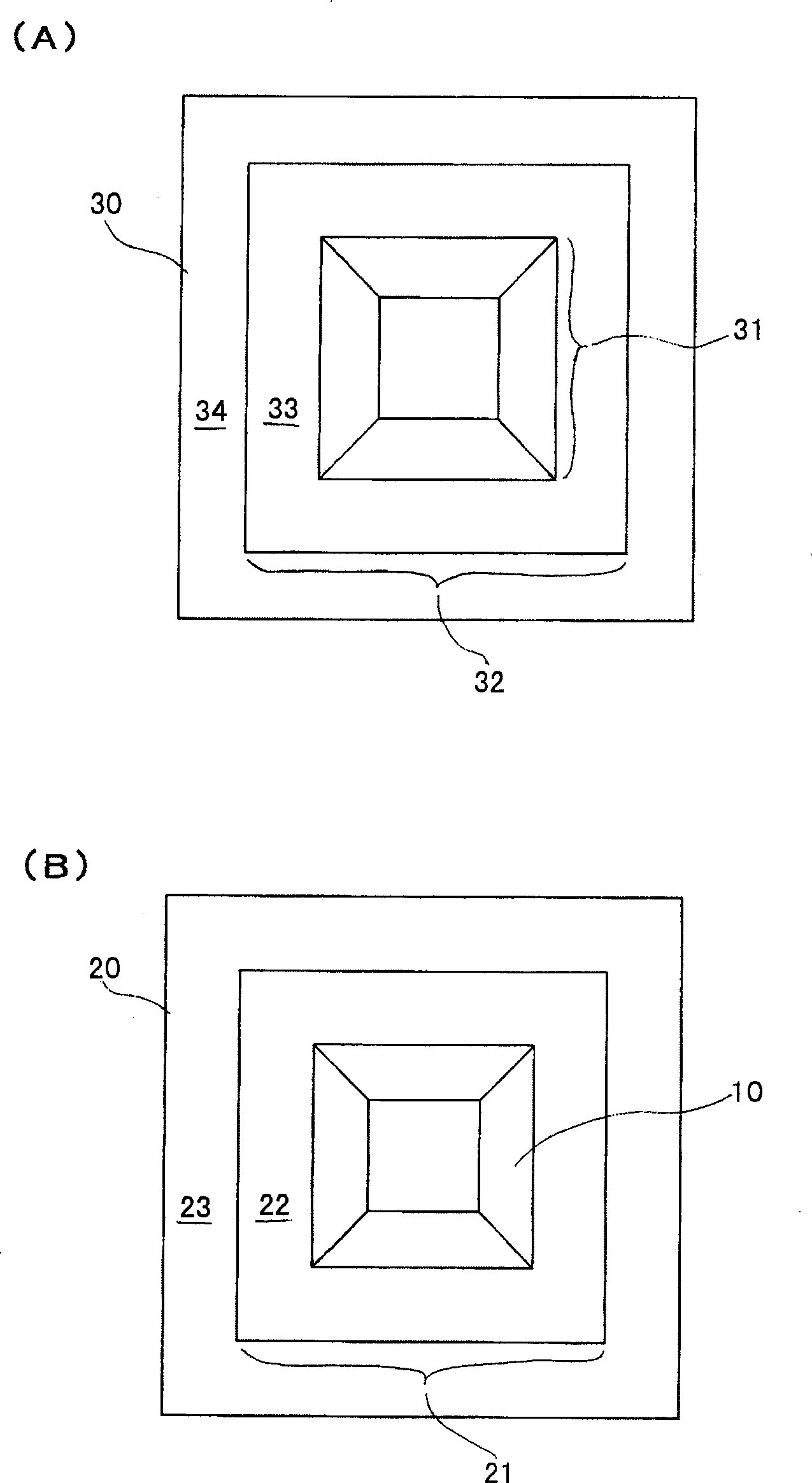

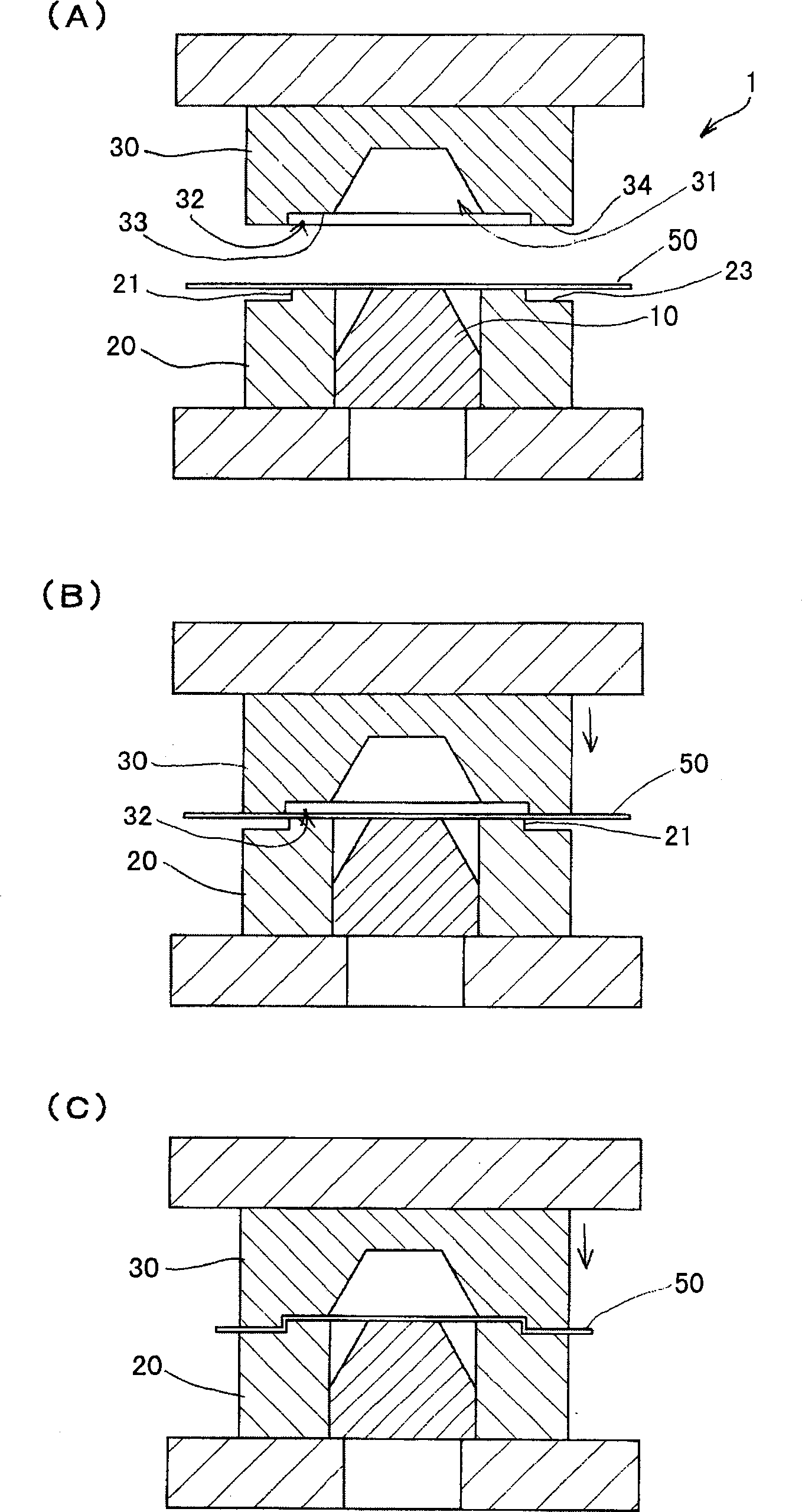

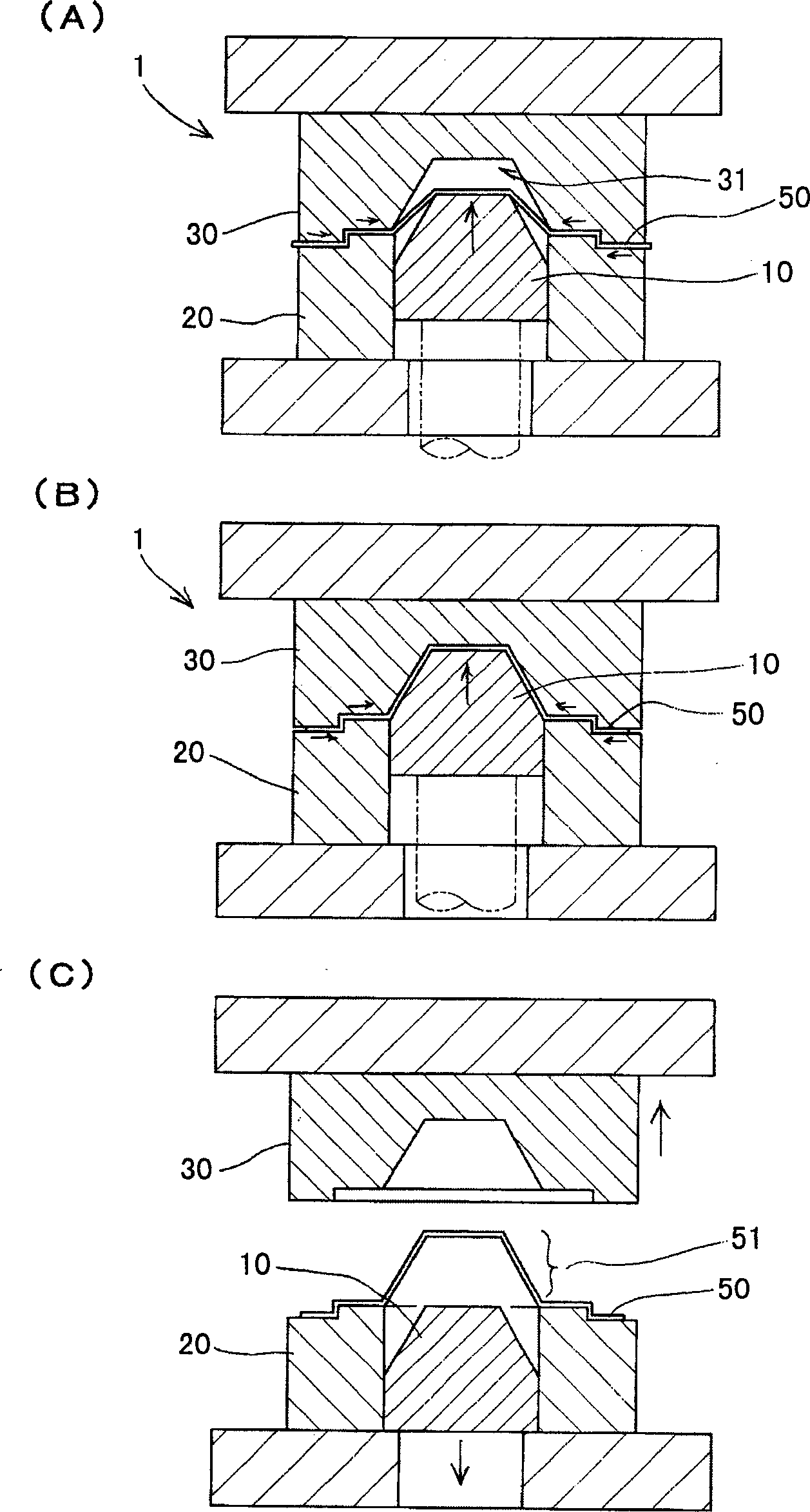

[0034] Below, according to Figure 1 to Figure 3 A first embodiment of the present invention will be described. figure 1 It is a bottom view of a die part and a top view of a punch part and a jig part of a die constituting a press device according to the present embodiment, figure 2 It is an explanatory diagram of the workpiece holding process of the press device related to the present embodiment. image 3 It is an explanatory diagram of a process of forming a workpiece by the press device according to the present embodiment.

[0035] The punching device related to this embodiment shown in the above-mentioned figures has a pair of metal molds 1 facing up and down, and the workpiece 50 made of a metal sheet that is put in and taken out between the upper and lower metal molds is made of metal. Die 1 is deep-drawn to form a square cone-shaped part for the exhaust port device. Each part of the press device other than the die 1 is a well-known structure, and its description is om...

no. 2 approach

[0049] according to Figure 4 to Figure 6 A second embodiment of the present invention will be described. Figure 4 It is a bottom view of a die part of a die constituting a press device according to a second embodiment of the present invention, and a plan view of a punch part and a jig part, Figure 5 It is an explanatory diagram of the workpiece holding process of the press device related to the second embodiment of the present invention, Figure 6 It is an explanatory diagram of a process of forming a workpiece by a press device related to the second embodiment of the present invention.

[0050] The press device related to this embodiment shown in the preceding figures has a pair of dies 1 as in the first embodiment, and the shape of the jig part 20 and the die part 30 constituting the die 1 is partially different. Structure. In addition, as in the above-mentioned first embodiment, each part of the press device other than the die 1 is a well-known mechanism, and descript...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com