Steel strand back-tension prestressed channel mudjacking method

A post-tensioning prestressing and channel grouting technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of tendon corrosion, anchorage connection cable shedding, strength reduction, etc., to achieve cement saving, reliable Protect and reduce working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

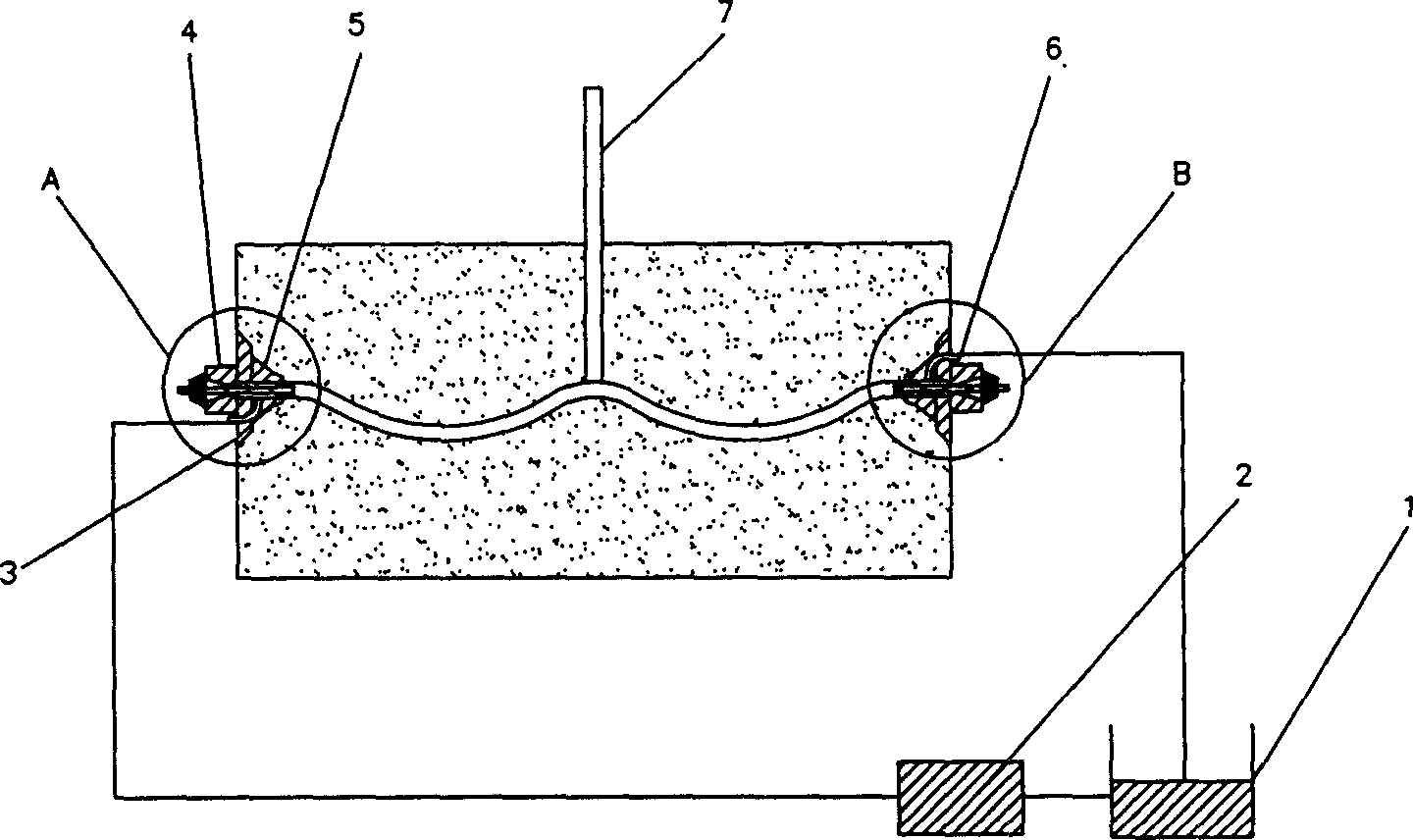

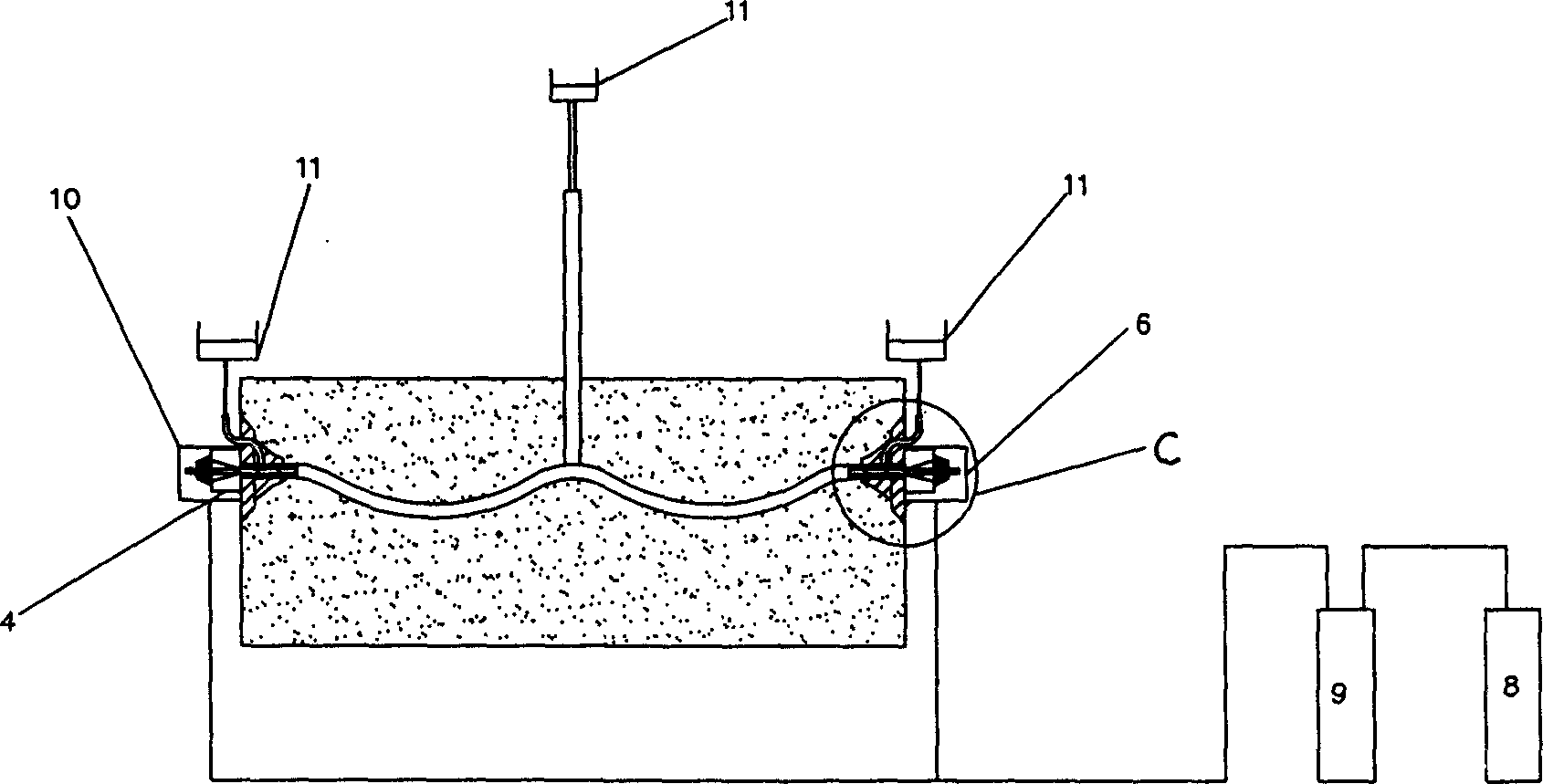

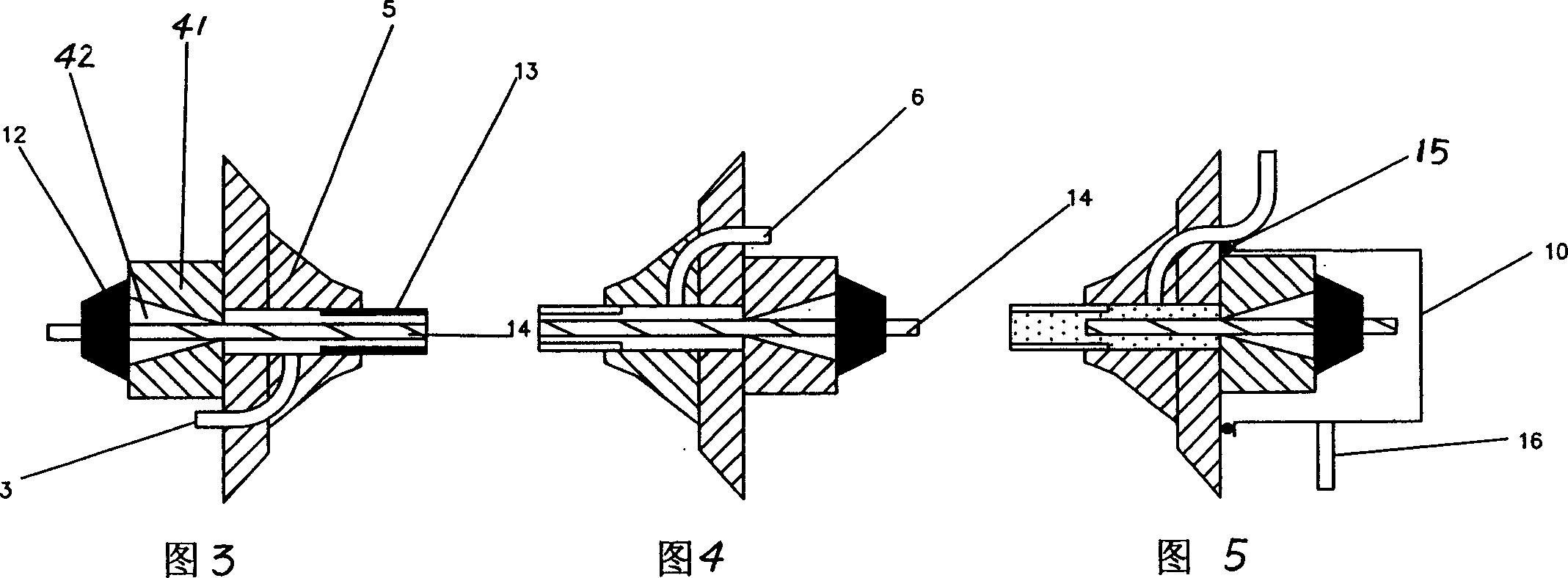

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] The main equipment used in the present invention includes cement slurry tank 1, grouting pump 2, anchorage 4, anchor seat 5, vacuum pump 8, gas-water separation tank 9, grout filling tank 11, steel strand 14 and supporting pipelines and valves ; There are various types of post-tensioned steel strands, which can be roughly divided into two categories: one is that the height difference between the two ends is not large, and the steel strand is bent upward, downward, or repeatedly bent; the other is the steel strand The wiring harness is unidirectionally inclined or even vertically arranged. In either case, the anchorage 4 at both ends of the steel strand 4 is provided with an anchor seat 5. There is a slurry inlet 3 or a slurry outlet 6, and the steel strand in the anchor seat is covered with a bellows 13, and the top of the prestressed channel in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com