Production of high-density topping filtering material from three gradient

A technology of filter material and manufacturing method, which is applied in the field of non-woven fabrics, can solve the problems of unsatisfactory dust stripping effect and difficult further improvement of filtration efficiency, and achieve good stripping effect, considerable economic benefits, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

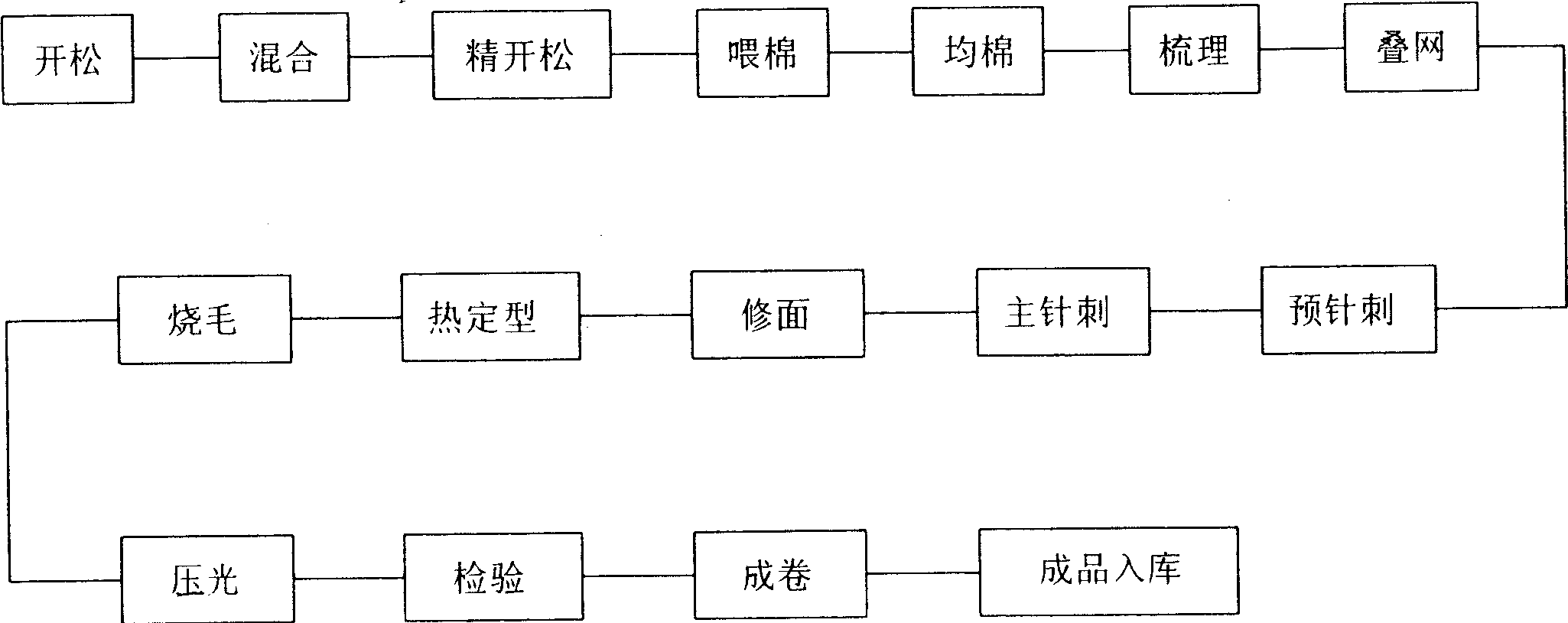

Method used

Image

Examples

Embodiment 1

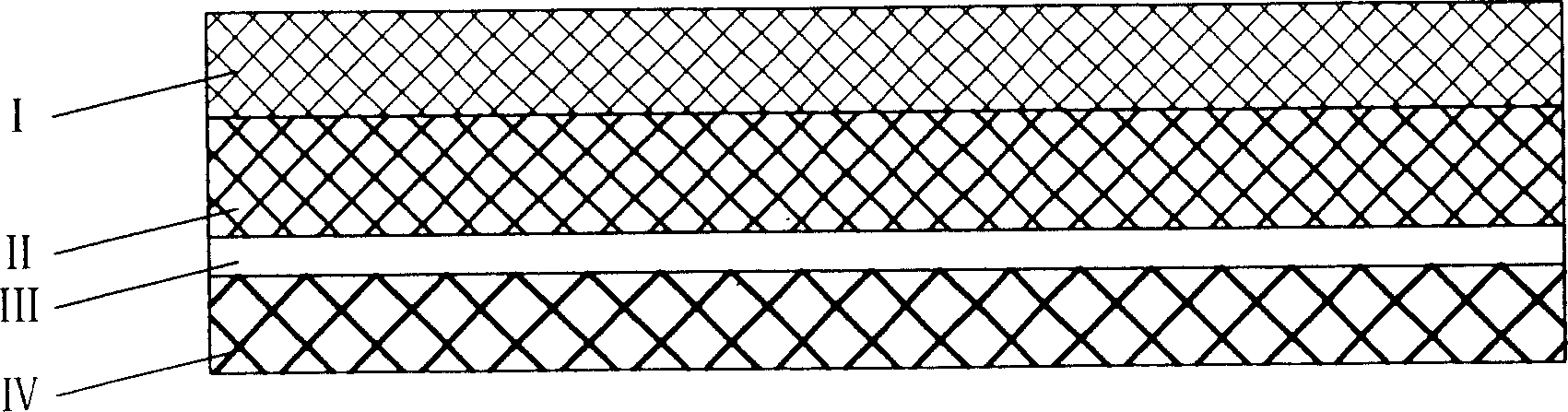

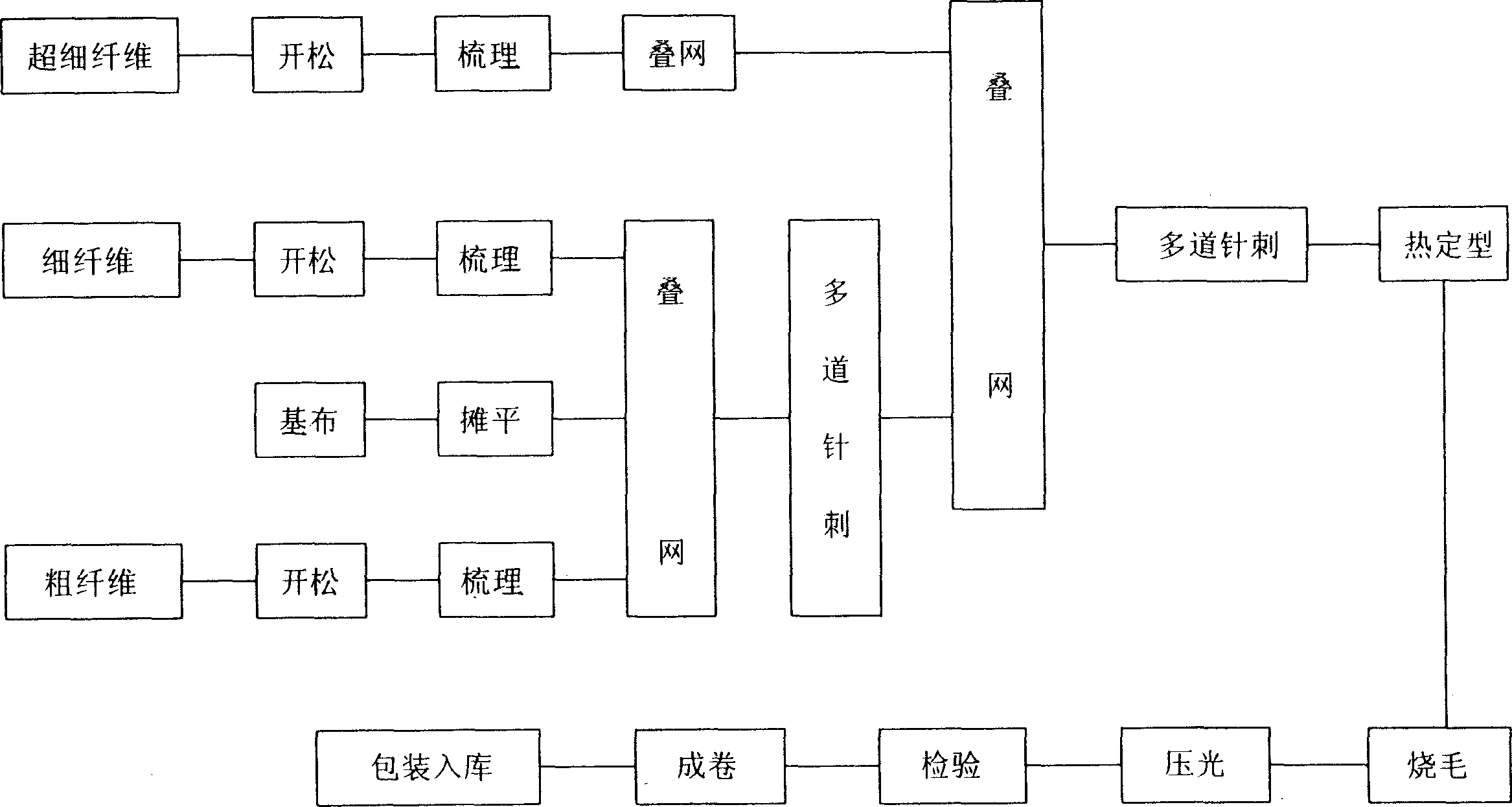

[0024] (1) Firstly, the 1.5dtex PPS fiber, glass fiber base cloth and 3.5dtex PPS fiber are used to form a two-layer fiber web with different fine and thick layers in the middle interlayer at the same time through the fiber-forming process equipment, and are fed into multiple needles together. Needle-punched blanks are formed by the loom, and the needle-punched density is 200 needles / cm 2 (2) Place a 0.85dtex PPS fiber net on the 1.5dtex PPS fiber net, and then enter the last few needle punching machines to perform needle felting, and the needle punching density is 200 needles / cm 2 (3) heat setting, singeing, and calendering of the needle felt to form a filter material with a three-gradient structure and a high-density surface layer with micropores and a smooth surface.

Embodiment 2

[0026] (1) Firstly, the process equipment of 1.5dtex polyester (PET) fiber, polyester (PET) base cloth and 4.5dtex polyester (PET) fiber are respectively collected into two fibers to form a web at the same time, and the upper and lower layers of the middle interlayer are formed at the same time. Layers of fiber web are fed into multi-channel needling machines together to form needling blanks with a needling density of 250 needles / cm 2 ; (2) Put 0.5dtex PET fiber net on the 1.5dtex PET fiber net, then enter the spunlace machine for spunlace, the spunlace density is 100 needles / cm 2 (3) After spunlace, the superfine fiber is used as the upper layer, the fine fiber is used as the middle layer, and the composite needle felt of polyester base cloth and thick fiber is heat-set, singeing, and calendered to make a three-dimensional felt. Gradient high-density surface layer microporous surface filter material.

[0027] Example

[0028] The above fiber codes are marked accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com