Device for tapwater pipe line directly pressurizating

A technology of tap water pipelines and booster devices, applied in water supply devices, water supply main pipelines, water supply pipeline systems, etc., can solve problems such as unavailability of pipeline pressure, water source end pipes affecting normal water use of water source end users, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

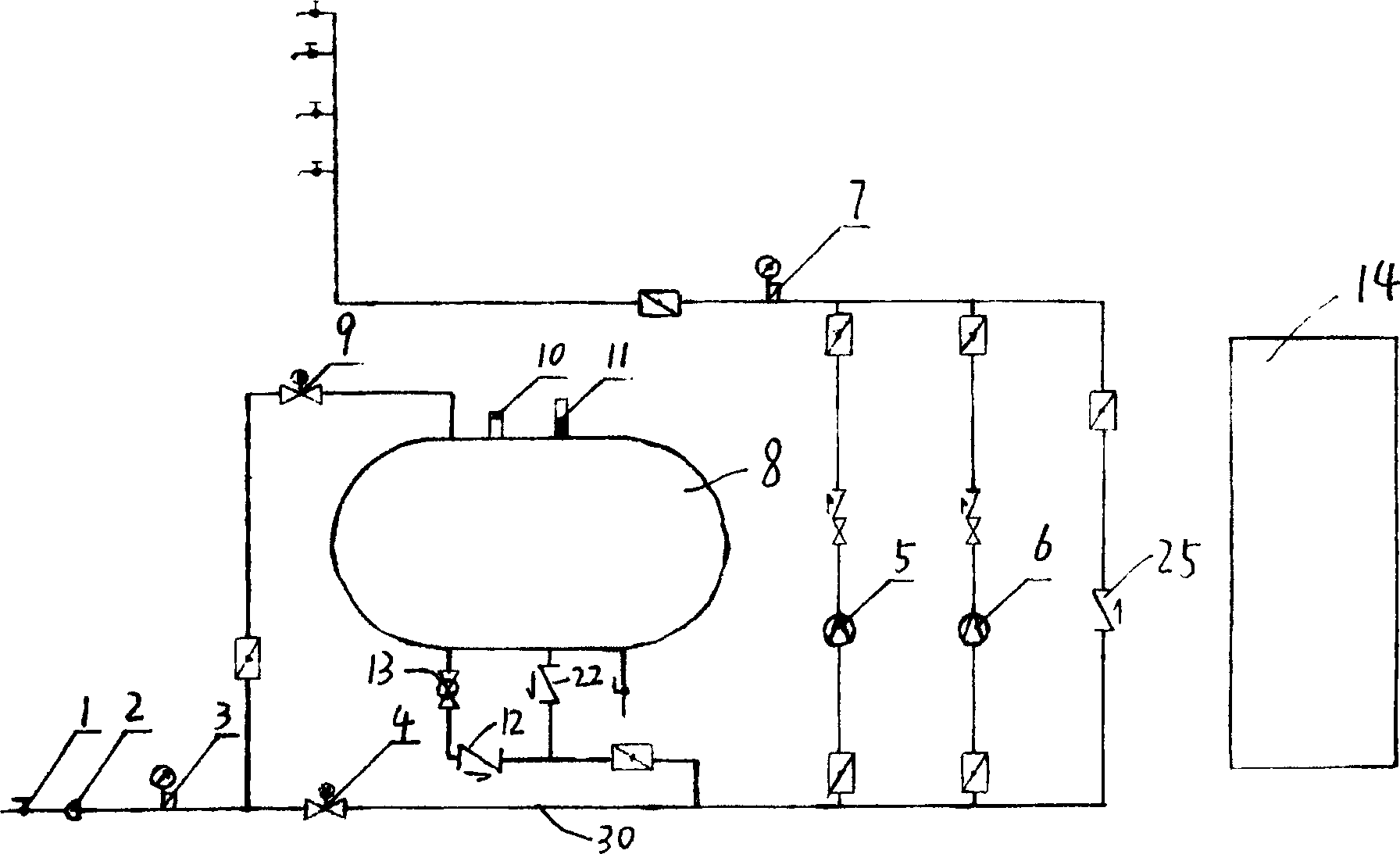

[0015] Example: see figure 1 , a direct pressurization device for tap water pipelines, mainly comprising: a first pressure gauge 3, a first electric valve 4, a first water pump 5, a second water pump 6, a second pressure gauge, a water collection tank 8, and a second electric valve 9 , the first check valve 12, the pipeline pump 13, the control cabinet 14, the water outlet of the first pressure gauge 3 communicates with the water inlets of the first and second electric valves 4 and 9 at the same time, and the water outlet of the second electric valve 9 communicates with the water outlet through the pipeline The water inlet of the water collecting tank 8 is connected, and the water collecting tank 8 is provided with three water outlets, the first water outlet is connected with the water inlet of the pipeline pump 13, and the second water outlet is connected with the water inlet of the second check valve 22, The third water outlet is provided with a gate valve for emptying. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com