New prefabricated landscape overflow weir

A prefabricated overflow weir technology, which is applied in barrage/weir, sea area engineering, construction, etc., can solve the problems of non-adjustable overflow weir, slow installation and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

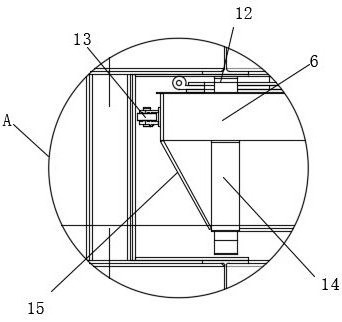

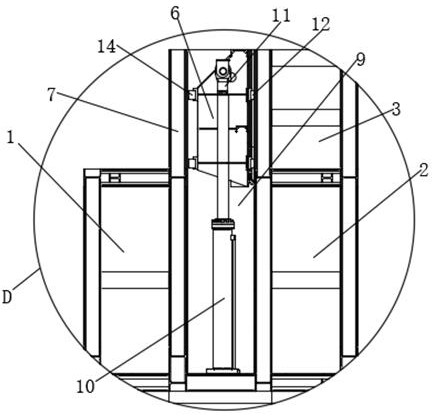

[0037] The new prefabricated landscape overflow weir includes a fixed frame 1, a stable frame 2, a bearing frame 3, a fixed steel pipe 4, a steel pipe groove 5, a straight lift gate 6 and a straight lift frame 7, the left side of the straight lift frame 7 and the right side of the fixed frame 1 The sides are fixedly connected, the right side of the lift frame 7 is fixedly connected with the left side of the stable frame 2, the upper end of the stable frame 2 is fixedly connected with the lower end of the bearing frame 3, steel pipe grooves are arranged on the left and right sides of the fixed frame 1, the stable frame 2 and the bearing frame 3 5. The fixed steel pipe 4 is movably socketed inside the steel pipe groove 5, and the vertical door 6 is movably socketed inside the lift frame 7. The outer side of the stable frame 2 and the bearing frame 3 are fixedly connected with the steel sheet pile 8 side, and the fixed The outer side of frame 1 is also fixedly connected with one s...

Embodiment 2

[0040] Embodiment 2: the difference based on Embodiment 1 is;

[0041] S1, survey the height of the river bottom, and determine the installation position of the fixed steel pipe 4;

[0042] S2, drive the fixed steel pipe 4 into the bottom of the river with a pile driver, and pay attention to controlling the relative size;

[0043] S3, fill up the river bottom in the area 4 of the 4 fixed steel pipes with gravel;

[0044] S4, align the steel pipe groove 5 on the weir body with 4 fixed steel pipes 4, and put it into the river bottom;

[0045] S5, the space between the fixed steel pipe 4 and the steel pipe groove 5 is poured with concrete;

[0046] S6. After the concrete is solidified, drive the steel sheet piles 8 on both sides into the river bottom;

[0047] S7. After fixing the steel sheet piles 8 on both sides, fill the gap with backfill soil and compact it;

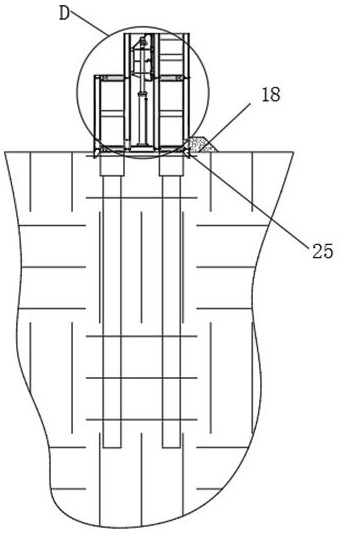

[0048] After the weir body of S4 is put into the river bottom, the underwater concrete 18 is filled on the side c...

Embodiment 3

[0050] Embodiment 3: the difference based on embodiment 1 and 2 is;

[0051] The steel sheet pile 8 is composed of a plurality of steel sheet pile assemblies 22, and the steel sheet pile assembly 22 includes a steel sheet pile beam 20, a steel sheet pile left connector 19 and a steel sheet pile right connector 21, and the left end of the steel sheet pile beam 20 is fixed to the right end of the steel sheet pile left connector 19 Connection, the right end of the steel sheet pile beam 20 is fixedly connected to the left end of the steel sheet pile right connector 21, the steel sheet pile left connector 19 matches the steel sheet pile right connector 21, and the steel sheet pile 8 adopts the SP-IV type Larsen steel sheet pile; the fixed frame 1 A plurality of support plates 16 and support slant columns 17 are provided on the outer side of the stability frame 2, the upper end of one support plate 16 is fixedly connected to one end of the support slant column 17, and the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com