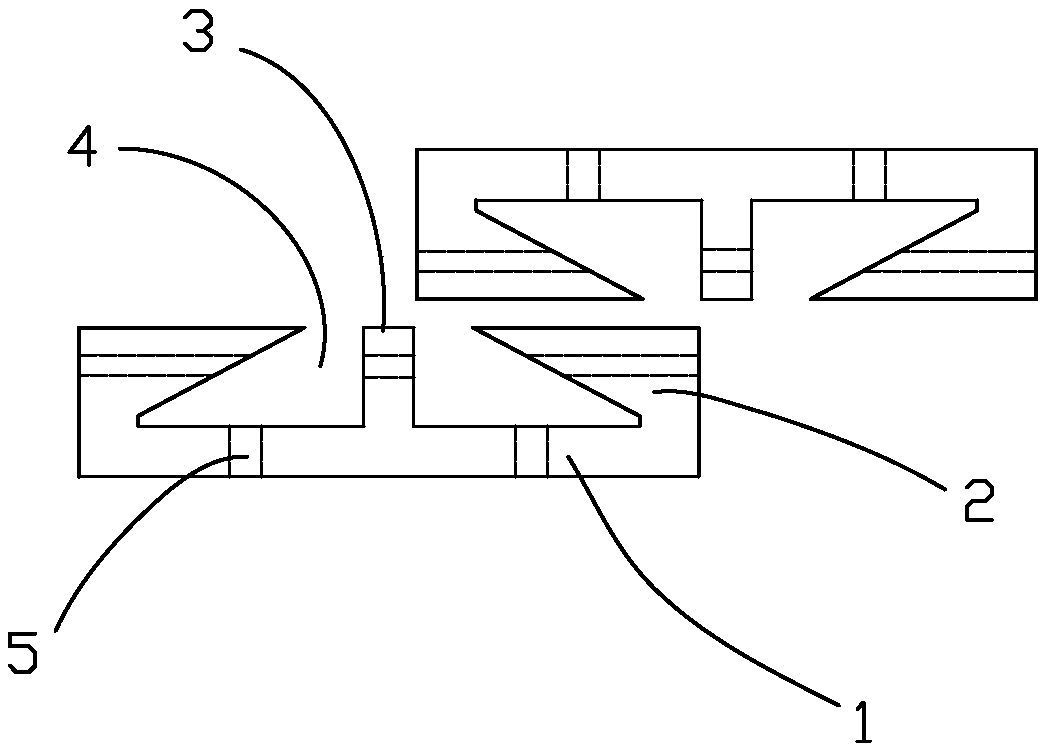

Self-locking slope protection brick

A slope protection brick and self-locking technology, applied in the direction of coastline protection, etc., can solve the problems of being vulnerable to the impact of slopes, landslides, and slope protection bricks cannot effectively resist, so as to avoid large-scale landslides, slow down corrosion speed, and improve water permeability and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Self-locking slope protection bricks are made of the following raw materials by weight: 46.5 parts of crushed stone, 23 parts of cement, 8.5 parts of silicomanganese slag, 1.6 parts of modifier, 0.8 parts of polycarboxylic acid water reducer, and ethylenediamine tetramethylidene 1.3 parts of sodium phosphonate and 5 parts of water. The modifier consists of potassium hydroxyethylene diphosphonate, polyamino polyether methylene phosphonic acid, sodium ethylenediamine tetramethylene phosphonate and sodium tolyltriazole according to 1:2.5:0.3 : 0.9 weight ratio mixing system. The particle size of the crushed stone is 5-25mm.

[0023] When making, first mix the silico-manganese slag and modifier uniformly to obtain modified silico-manganese slag; then mix the modified silico-manganese slag with the rest of the raw materials uniformly to obtain a mixture; finally place the mixture in the mold to vibrate and pressurize Molding, the pressure is 8MPa, and air dry after demolding....

Embodiment 2

[0025] Self-locking slope protection brick, made of the following raw materials by weight: 40 parts of gravel, 25 parts of cement, 5 parts of silico-manganese slag, 2 parts of modifier, 0.5 parts of polycarboxylic acid water reducing agent, ethylenediamine tetramethylene 2 parts of sodium phosphonate and 2.8 parts of water. The modifier consists of potassium hydroxyethylene diphosphonate, polyamino polyether methylene phosphonic acid, sodium ethylenediamine tetramethylene phosphonate and sodium tolyltriazole according to 1:3:0.1 : The weight ratio of 1.2 is mixed. The particle size of the crushed stone is 5-25mm.

[0026] When making, first mix the silico-manganese slag and modifier uniformly to obtain modified silico-manganese slag; then mix the modified silico-manganese slag with the rest of the raw materials uniformly to obtain a mixture; finally place the mixture in the mold to vibrate and pressurize Molding, the pressure is 8MPa, and air dry after demolding.

Embodiment 3

[0028] Self-locking slope protection brick, made of the following raw materials by weight: 50 parts of crushed stone, 20 parts of cement, 13 parts of silicomanganese slag, 1 part of modifier, 1 part of polycarboxylic acid water reducing agent, ethylenediamine tetramethylidene 1 part of sodium phosphonate and 6 parts of water. The modifier consists of potassium hydroxyethylene diphosphonate, polyamino polyether methylene phosphonic acid, sodium ethylenediamine tetramethylene phosphonate and sodium tolyltriazole according to 1:2:0.4 : 0.6 weight ratio mixing system. The particle size of the crushed stone is 5-25mm.

[0029] When making, first mix the silico-manganese slag and modifier uniformly to obtain modified silico-manganese slag; then mix the modified silico-manganese slag with the rest of the raw materials uniformly to obtain a mixture; finally place the mixture in the mold to vibrate and pressurize Molding, the pressure is 9MPa, and it can be air-dried after demolding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com