Graded loaded sample preparation method of cement soil direct shear sample

A graded loading and cement-soil technology, applied in the preparation of test samples, etc., can solve the problems of large human errors, errors, and difficulty in forming samples, and achieve the effect of high cost performance, simple structure, and avoiding disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

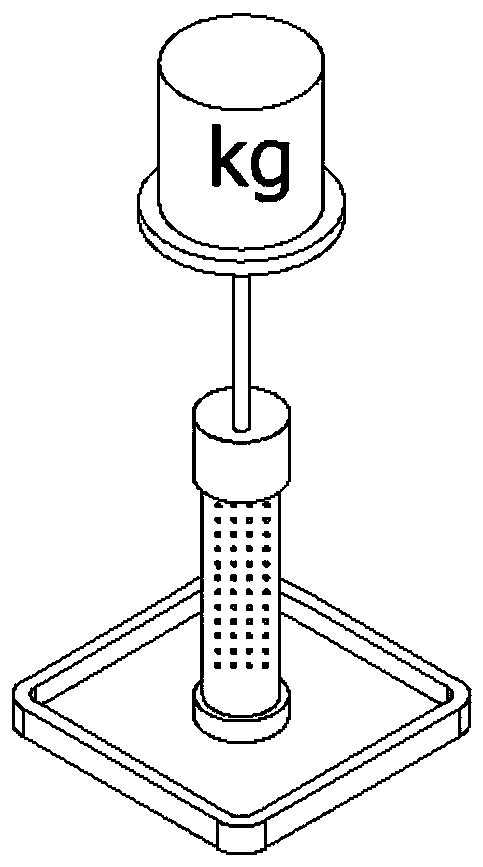

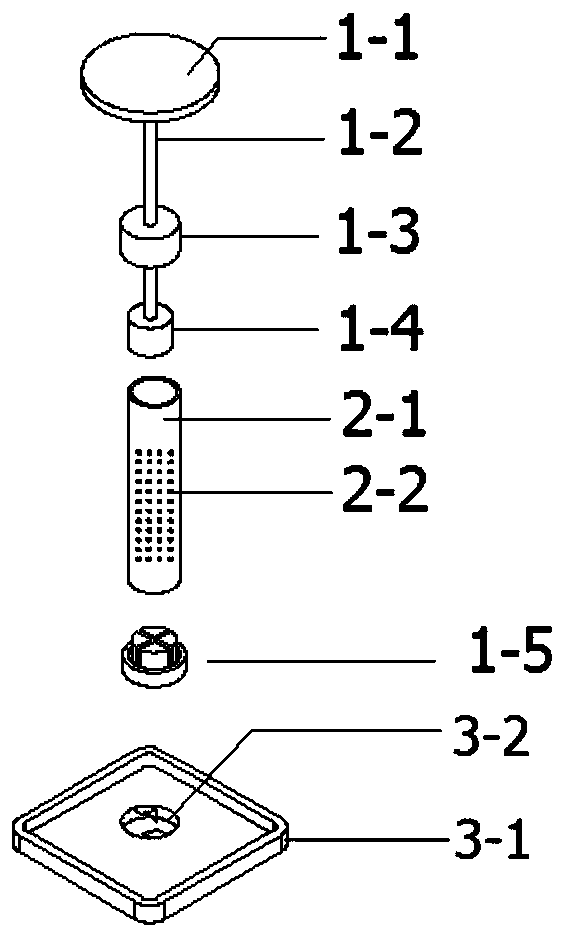

[0051] As shown in the figure, a method for preparing samples of cement-soil direct shear samples with graded loading in the present invention, wherein the sample preparation device involved includes a pressure applying mechanism 1, a sample receiving mechanism 2, a supporting mechanism 3, a cutting mechanism 4, Soil injector 5.

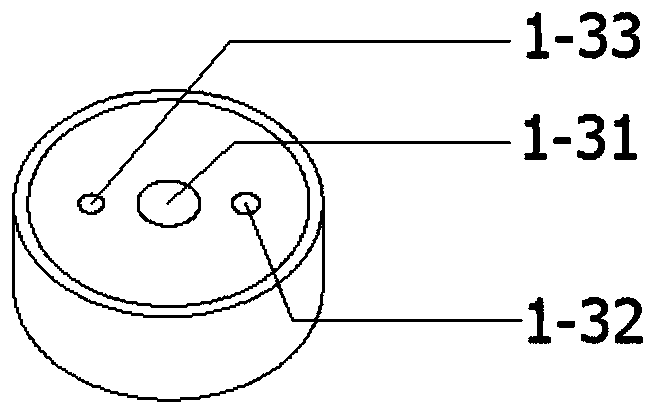

[0052] Wherein, the pressing mechanism 1 is composed of a bearing plate 11 , a force transmission shaft 12 , a pressing fixed cover 13 , a pressing disk 14 and a pressure receiving disk 15 .

[0053] The bearing plate 11 is a disc with a diameter of 150 mm and a thickness of 15 mm, on which weights of different weights can be placed to provide vertical pressure for the entire device.

[0054] Power transmission shaft 12 is the cylinder of diameter 20mm, high 220mm, and one end is fixedly connected with the center of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com