Plate heat exchanger with condensed fluid separating functions and its manufacturing method

A technology for heat exchangers, condensing liquids, applied in separation methods, heat exchange equipment, chemical instruments and methods, etc., can solve problems such as reducing size and weight, heat transfer loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

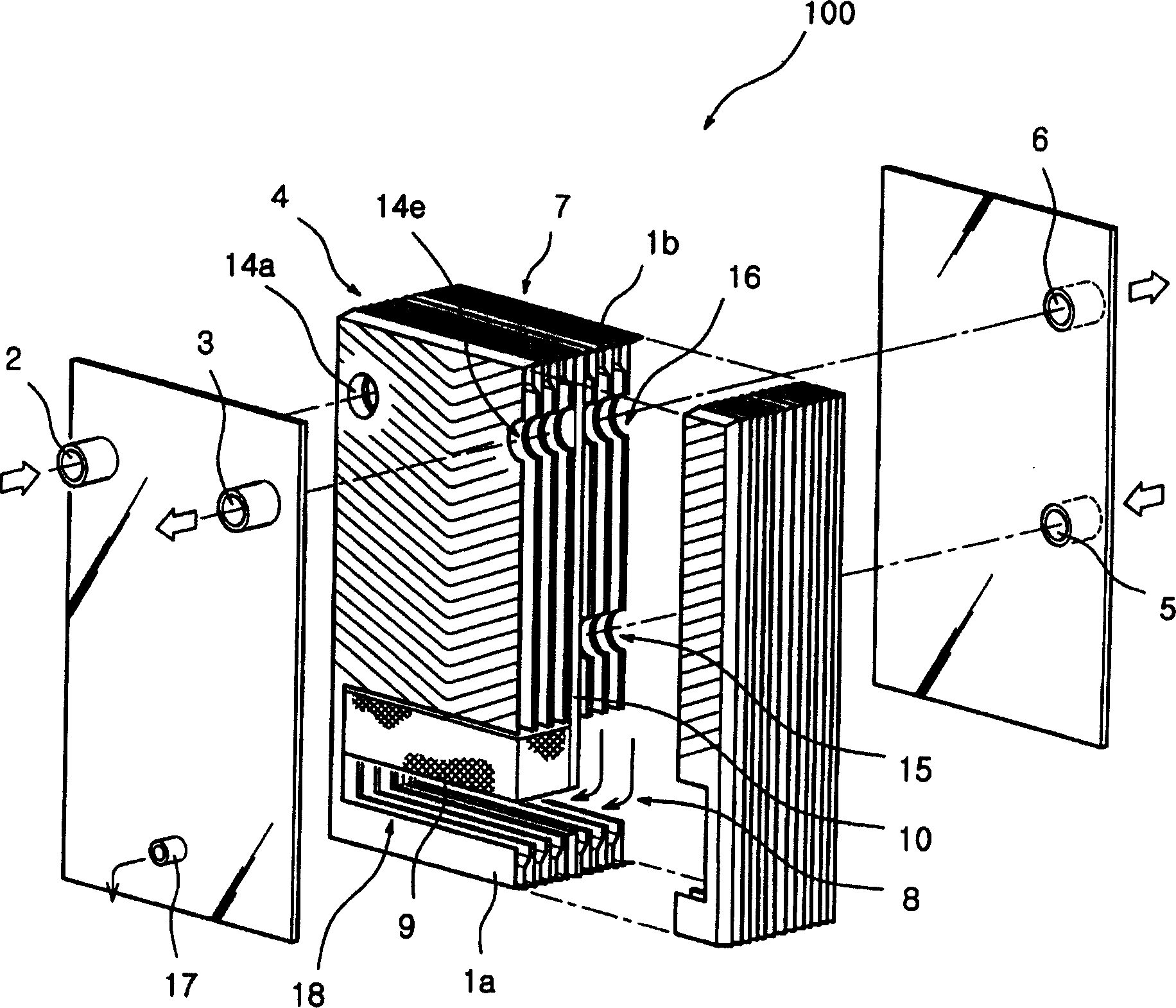

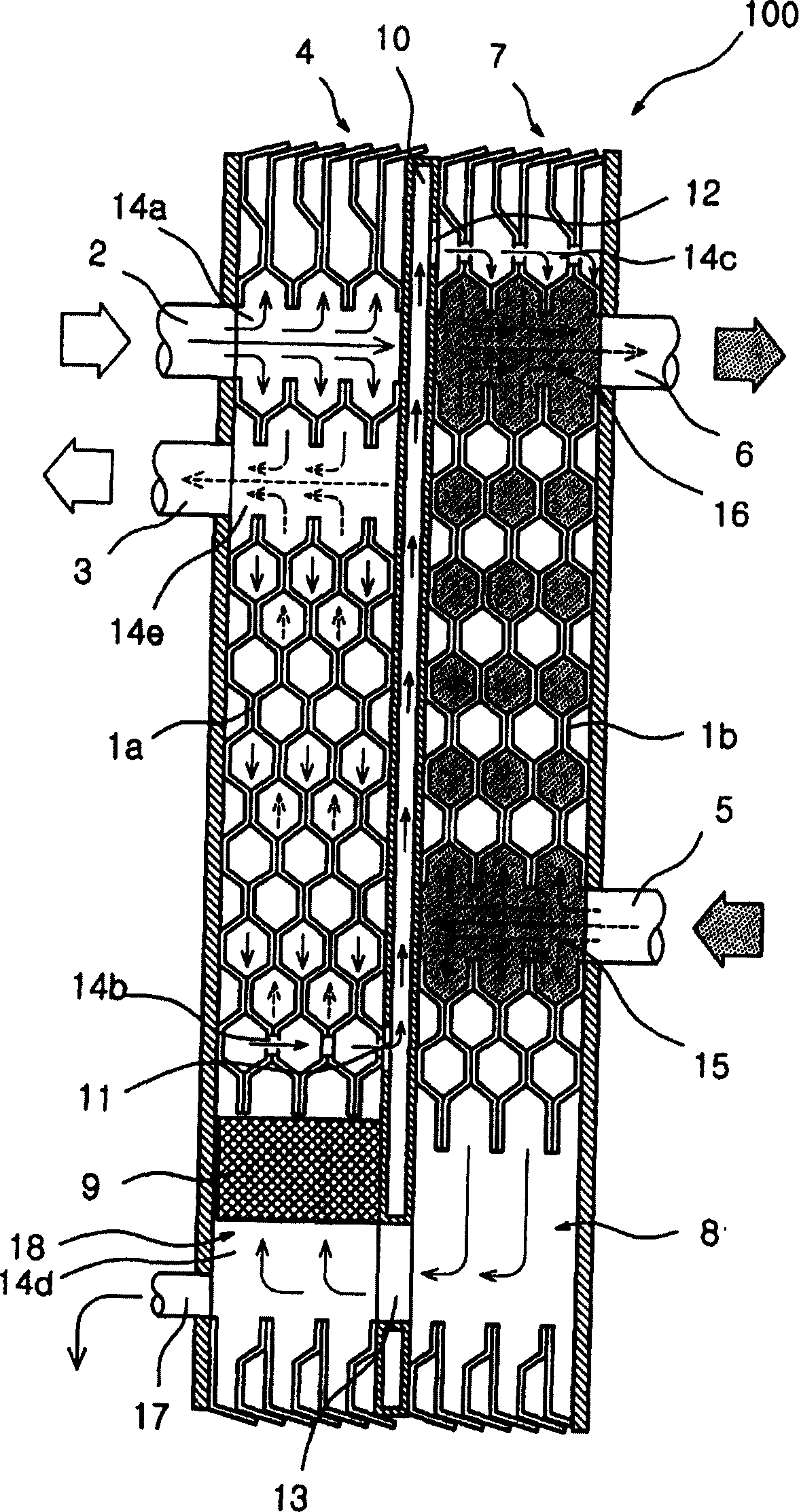

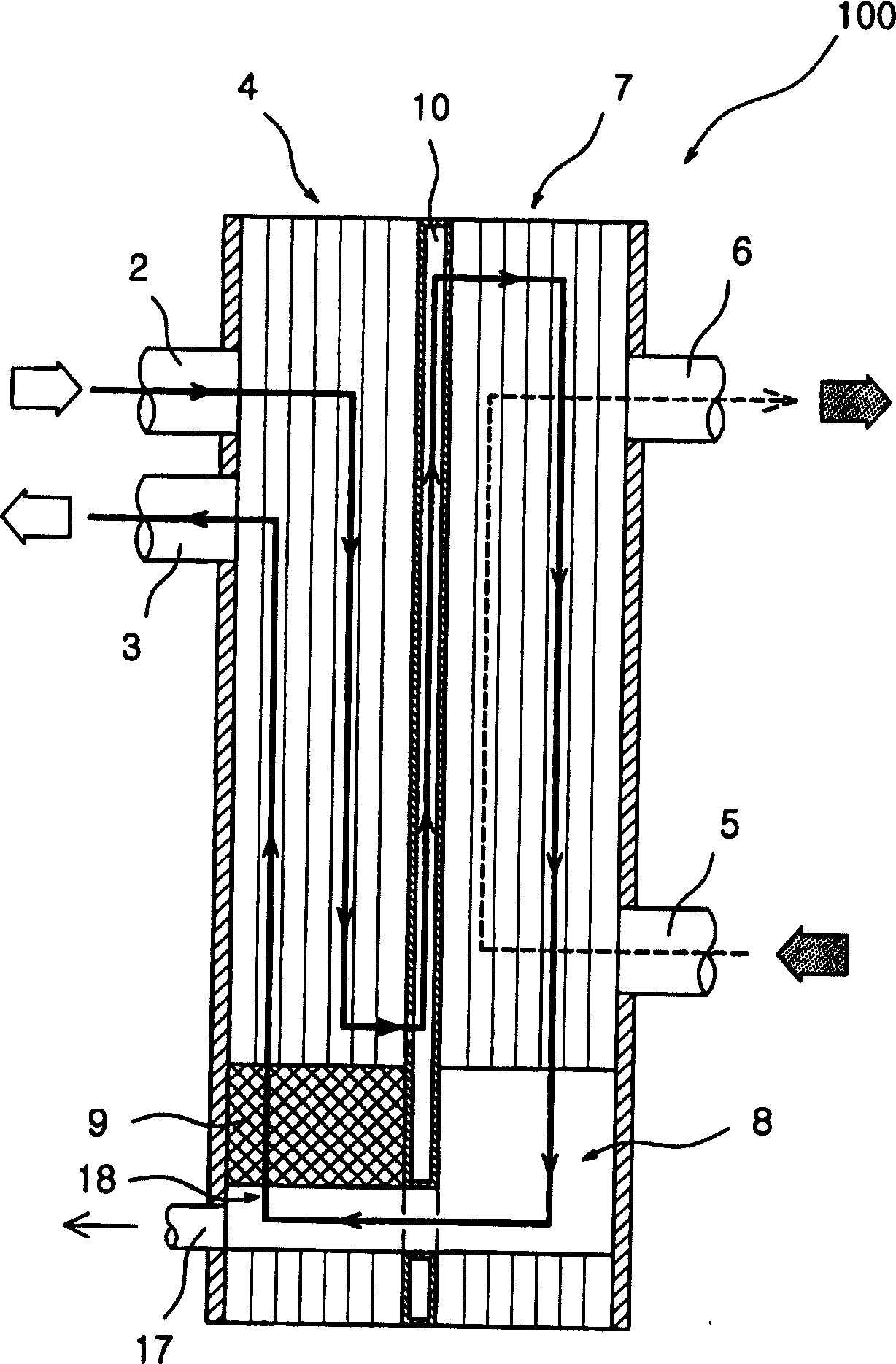

[0014] figure 1 is an exploded perspective view of a plate heat exchanger according to the present invention, figure 2 is a cross-sectional view of the plate heat exchanger, image 3 Indicates the flow of compressed air and working fluid in a plate heat exchanger.

[0015] Such as figure 1 and 2 As shown, the integrated plate heat exchanger 100 with condensate separation function according to the present invention comprises a regenerator 4 having a plurality of corrugated plates 1a laminated therein, wherein two internal air passages are formed by means of the laminated plates 1a , so as to be connected to the inlet hole 2 and the outlet hole 3; and a cooler 7 having a plurality of laminated corrugated plates 1b to form two internal passages therein, wherein the working fluid connected to the working fluid passage in the passage An inlet hole 5 and a worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com