Electromagnetic operation device

An electromagnetic operation and electromagnetic technology, applied in circuits, electrical switches, electrical components, etc., can solve the problems of vacuum valve opening time deviation, difficulty in saving space, and inability to stably cut off the system, and achieve the effect of stable disconnection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

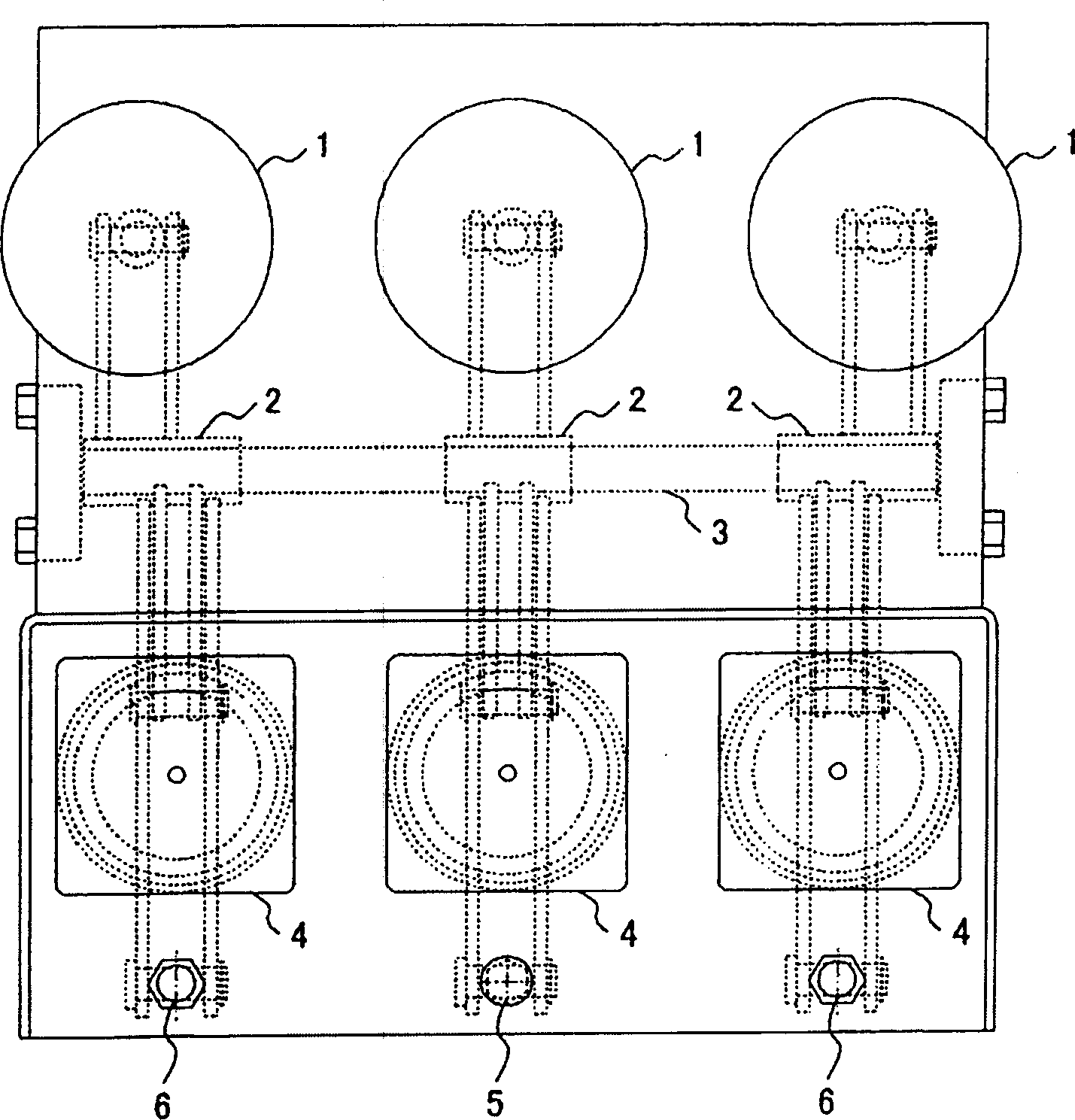

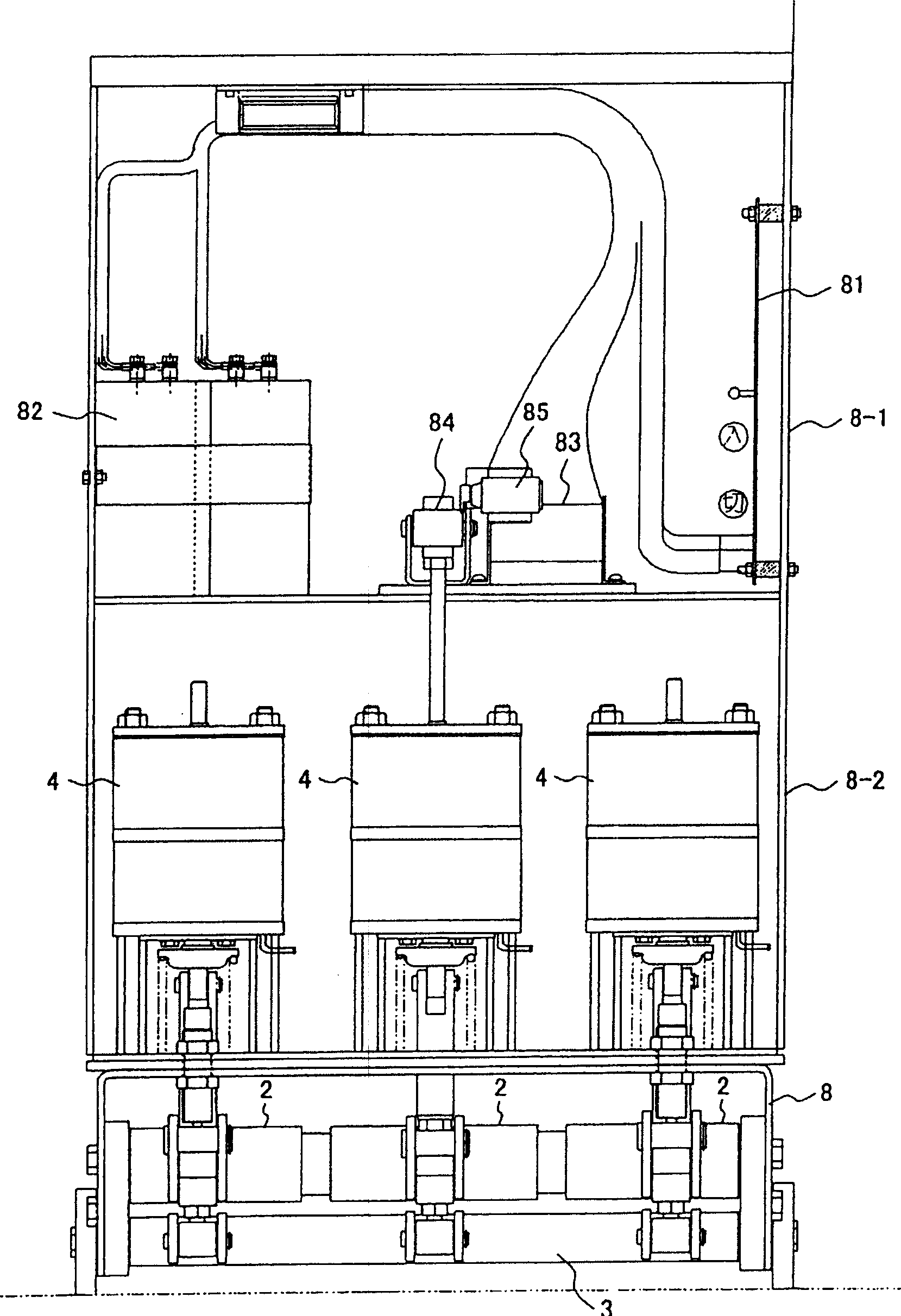

[0023] figure 1 is a top view of the electromagnetic operating device of the present invention, figure 2 is the front view including the electromagnetic manipulator and controller, Figure 3A , Figure 3B is a side view including the main shaft and the three-phase connecting shaft.

[0024] Such as figure 1 As shown, the vacuum valves 1 of each phase are respectively connected to the electromagnetic operator 4 through the main shaft 2 . The main shafts 2 freely start to move in each phase, and are connected by a three-phase connection shaft 3 as described later, so that synchronization among the main shafts 2 is obtained.

[0025] Such as figure 2 As shown, the electromagnetic operating device is accommodated in a box-shaped multi-segment frame body 8, controllers such as a control board 81 and a capacitor 82 are accommodated in the upper segment 8-1, and the electromagnetic operator 4 is accommodated in the middle segment 8-2. . As shown in the figure, the upper sect...

Embodiment 2

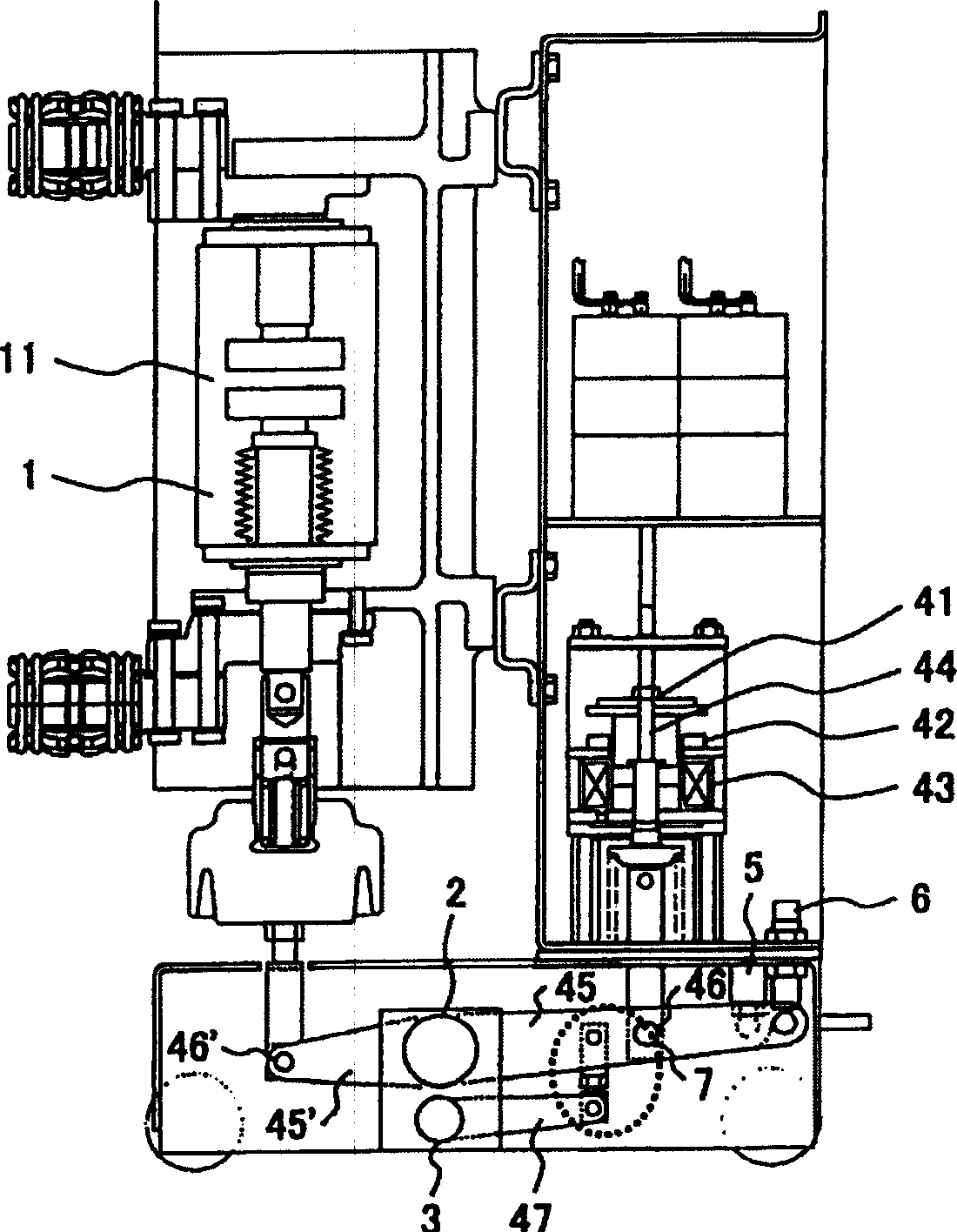

[0039] A second embodiment of the present invention will be described below. Figure 5 , Image 6 It is an embodiment in which the three-phase connection shaft 3 is arranged on the upper part of the electromagnetic operator 4 .

[0040] The three-phase connection shaft 3 is arranged on the upper side of the electromagnetic operator 4 , and the main shaft 2 is arranged on the lower side of the electromagnetic operator 4 . The connection of the two axes is performed by the rod 44 of the electromagnetic operator 4 . That is, since the rod 44 is connected to the vane 45 of the main shaft 2 via the fulcrum 46 , the movement of the rod 44 can be transmitted to the vane 47 of the upper three-phase connection shaft 3 . Thus, the three-phase connection shaft 3 can achieve synchronization among the respective main shafts 2 .

Embodiment 3

[0042] A third embodiment of the present invention will be described below. Figure 7 This is an example in which the three-phase connection shaft 3 is arranged on the vacuum valve 1 side. The difference from the first embodiment is that the three-phase connecting shaft 3 is arranged on the lower part of the main shaft 2 on the side of the vacuum valve 1 . The connecting portion 7 is provided between the vane 45' on the vacuum valve 1 side of the main shaft 2 and the vane 47 of the three-phase connecting shaft 3. The linked action is the same as in the first embodiment.

[0043]The three embodiments described above should be appropriately selected according to the configuration of the electromagnetic operation device. For the first and third embodiments, the main shaft and the three-phase connection shaft are arranged in the same frame area, so it is easy to assemble or Adjustment. On the other hand, the second embodiment has a structure that does not require a connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com