Technique for molding adobe of ceramic brick

A technology of ceramic bricks and bricks, which is applied in the field of stone-like ceramic bricks, and can solve the problem that the color distribution cannot achieve the realistic effect of natural stone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

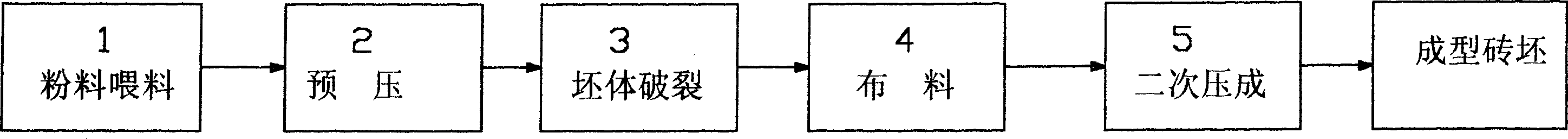

[0013] A ceramic tile forming technology of the present invention includes three parts: a mould, a press and a cloth, and adopts a unique design and technology to coordinate and cooperate with each other to complete the molding of the ceramic blank. The ceramic tile has a realistic imitation stone effect.

[0014] On the basis of the first powder feeding, it is completed through the following implementation steps.

[0015] The first step: pre-press forming; pre-press the ceramic powder into adobe through the mold, distribution system and press.

[0016] The second step: breaking the adobe; through the unique structure and method, the adobe protected in the mold cavity is broken and gaps appear.

[0017] The third step: cloth; add another ingredient (after firing, ensure that it is different from the color of the base blank). Sprinkle on the cracked and textured brick surface and fall into the gap.

[0018] The fourth step: the second forming; with the full pressure required ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap