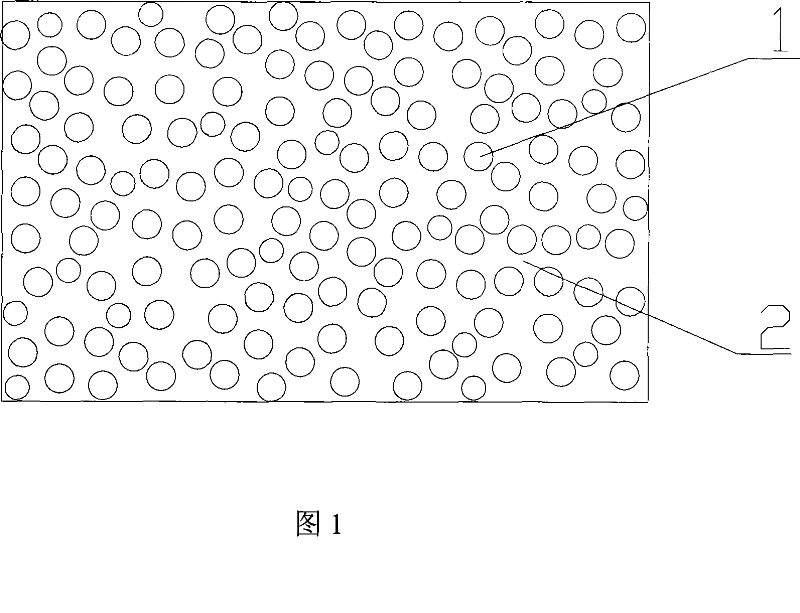

Porous light hollow brick

A hollow brick, lightweight technology, applied in the field of building wall thermal insulation and energy saving, can solve the problems of increasing building weight, increasing cost, and reducing the total amount of use, so as to achieve environmental protection, reduce resource consumption, reduce effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The foamed plastic with a volume percentage of 20% and the clay with a volume percentage of 80% are mixed and stirred evenly to make bricks, and fired according to the process to obtain porous lightweight hollow bricks. After testing, the bulk density, thermal conductivity and pressure bearing capacity of the brick are respectively: 1448kg / m 3 , 0.231W / (m·K), 1.53MPa.

Embodiment 2

[0020] The foamed plastic with a volume percentage of 30% and the clay with a volume percentage of 70% are mixed and stirred evenly to make bricks, which are fired according to the process to obtain porous lightweight hollow bricks. After testing, the bulk density, thermal conductivity and pressure bearing capacity of the brick are respectively: 1235kg / m 3 , 0.207W / (m·K), 1.36MPa.

Embodiment 3

[0022] The foamed plastic with a volume percentage of 40% and the clay with a volume percentage of 60% are mixed and stirred evenly to make bricks, and fired according to the process to obtain porous lightweight hollow bricks. After testing, the bulk density, thermal conductivity and pressure bearing capacity of the brick are respectively: 1087kg / m 3 , 0.182W / (m·K), 1.18MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure endurance | aaaaa | aaaaa |

| Pressure endurance | aaaaa | aaaaa |

| Pressure endurance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap