Centrifugal pump

A centrifugal pump and pump housing technology, applied in the field of centrifugal pumps, can solve problems such as efficiency effects, and achieve the effects of improving efficiency, increasing volume flow, and improving flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

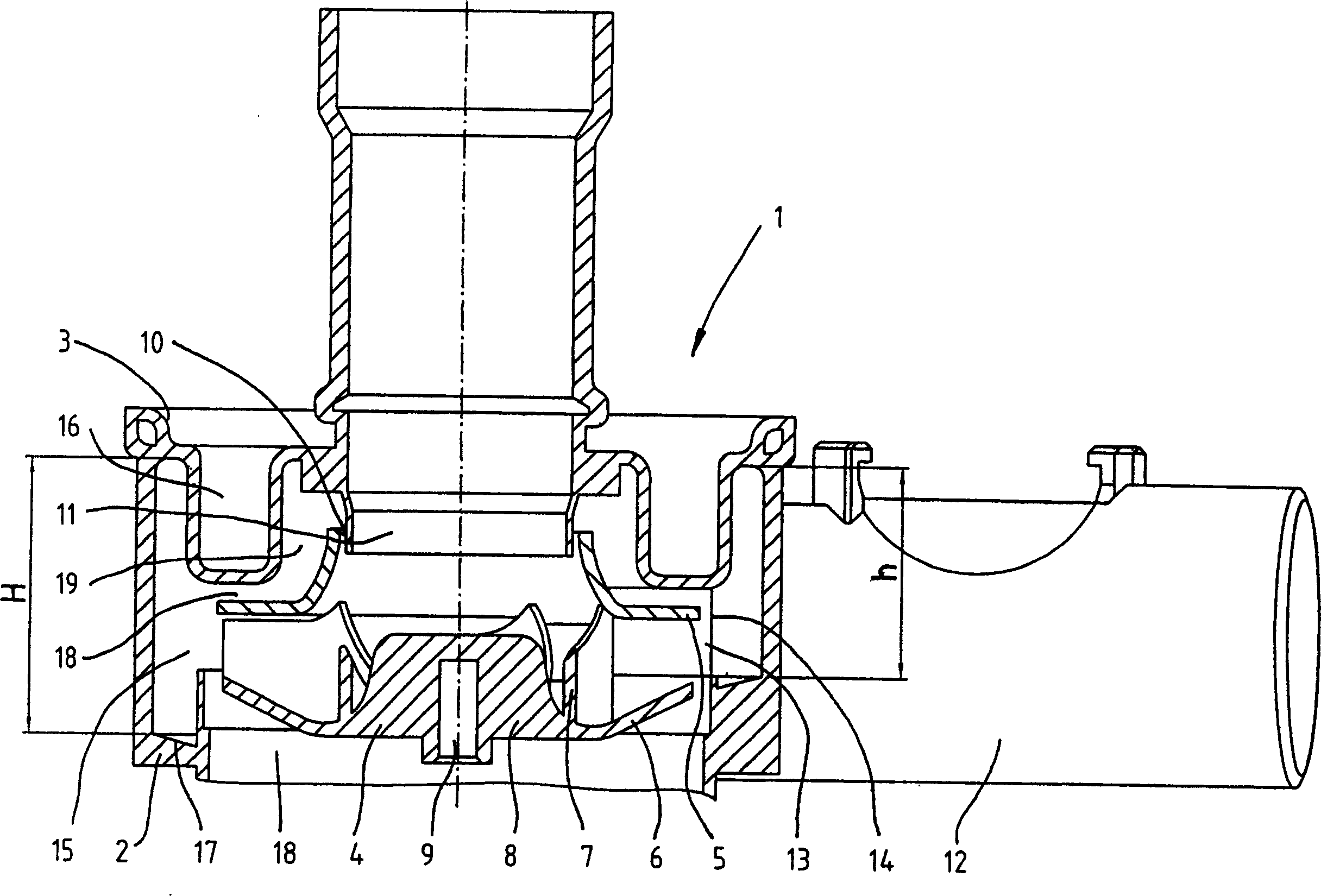

[0029] according to figure 1 The pump 1 includes a cylindrical pump housing 2, on which a cover 3 is mounted. Cover 3 can accommodate figure 1 The heating element is not shown, for which the cover is made of a thermally conductive material, such as metal.

[0030] Arranged within the pump housing 2 is a pump impeller 4 which essentially consists of an upper cover 5 and a lower cover 6 with blades 7 arranged therebetween. The blades 7 are bent and shaped in such a way that, when the pump impeller 4 rotates, a corresponding annular flow of the liquid in the pump impeller 4 results.

[0031] The pump impeller 4 is provided on the underside with an axial projection 8 which has a central bore 9 for receiving a drive shaft, not shown in detail. The pump impeller 4 is thus driven from the side opposite the heating element or cover 3 .

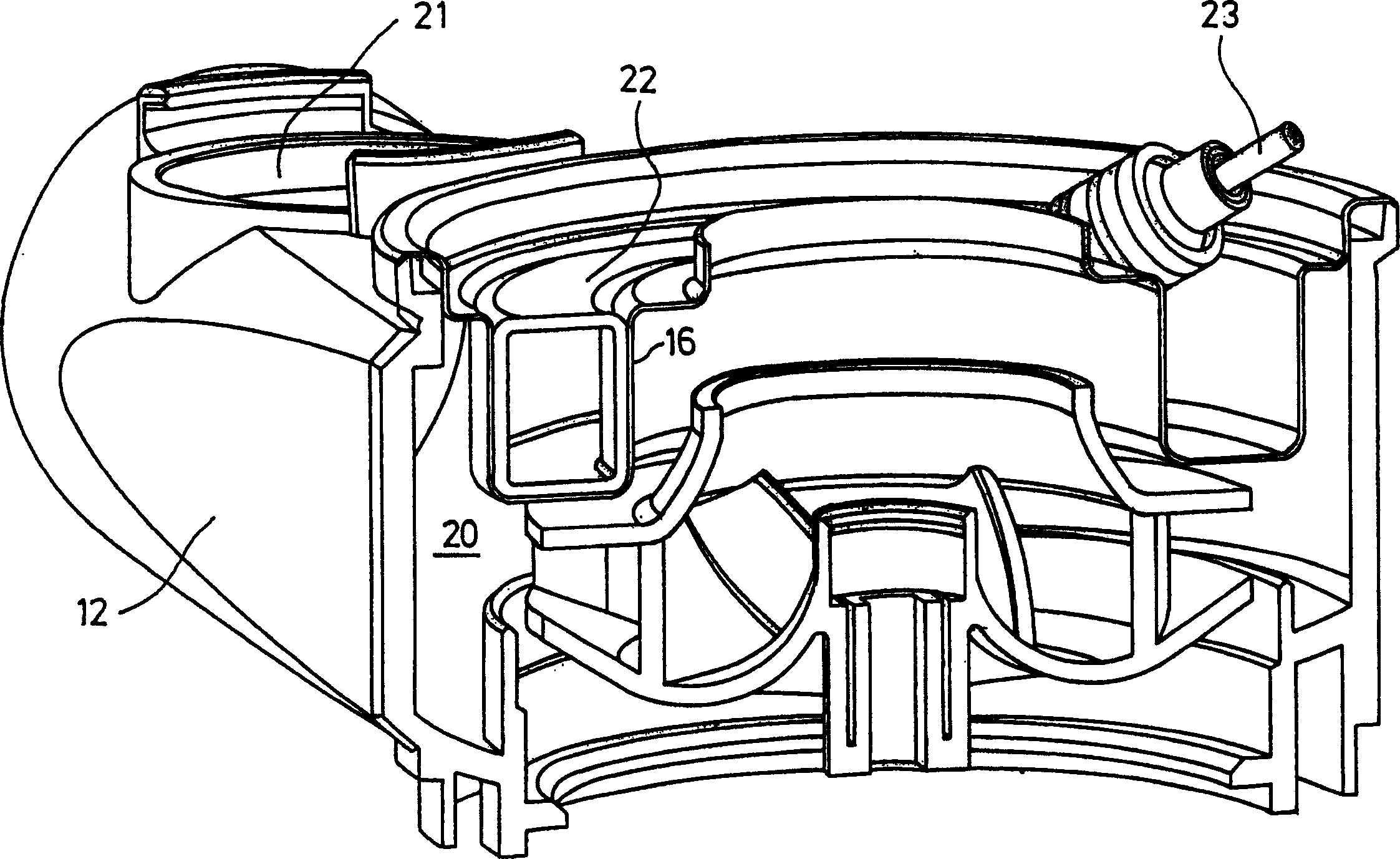

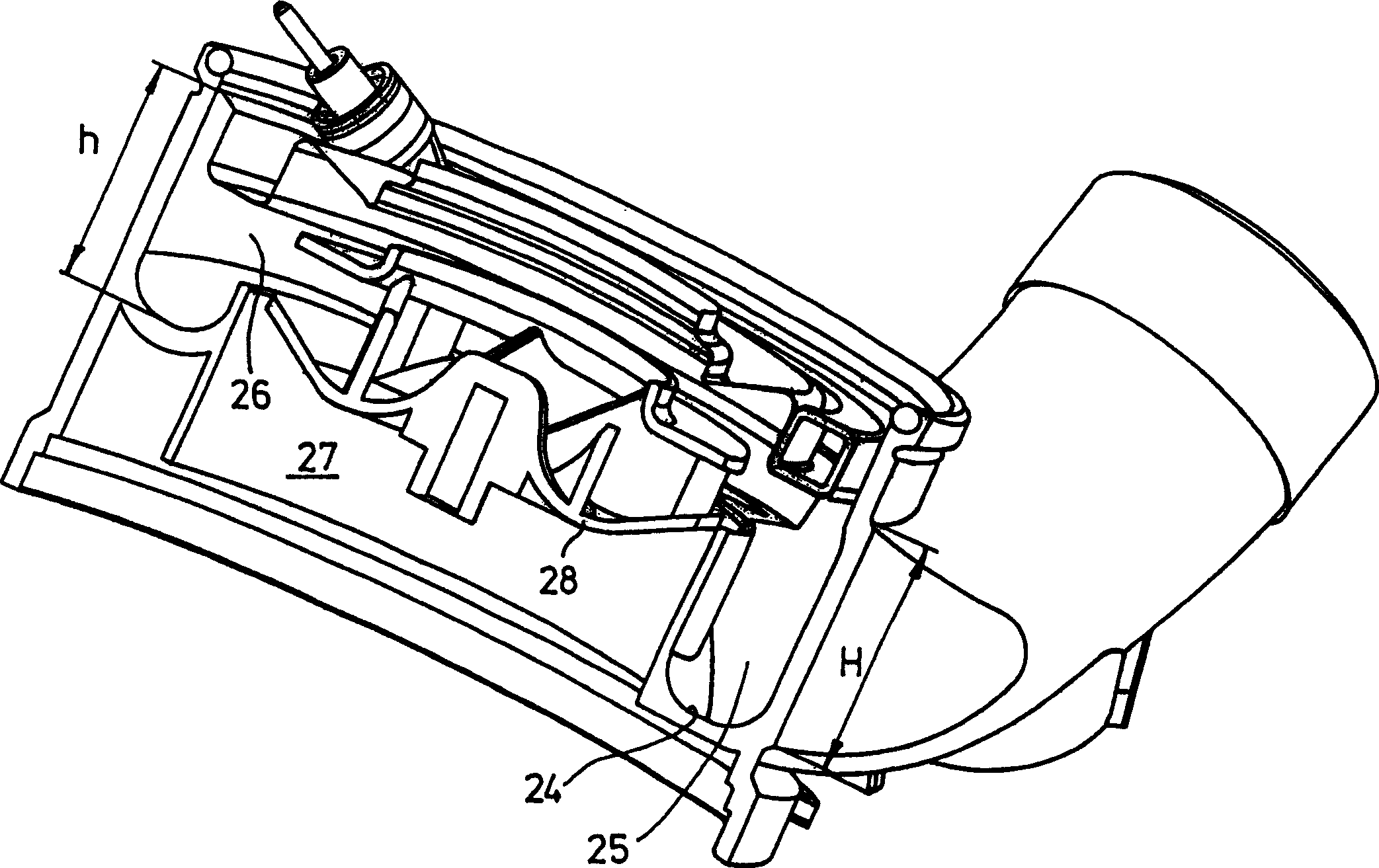

[0032] The upper cover 5 has a central opening 10 into which an inlet connection 11 protrudes. An outlet pipe joint 12 in image 3 Mounted tang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com