Faceplates of lamp house cover, and openable type combinatorial injection molding lamp house

A cover panel and open-type technology, which is applied in the field of boards and light boxes combined with the boards, can solve the problems of unreasonable force on the box structure, inconvenient disassembly and assembly of light boxes, waste of leftover materials, etc., and achieve simple and convenient assembly , good stereo vision effect, fast installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

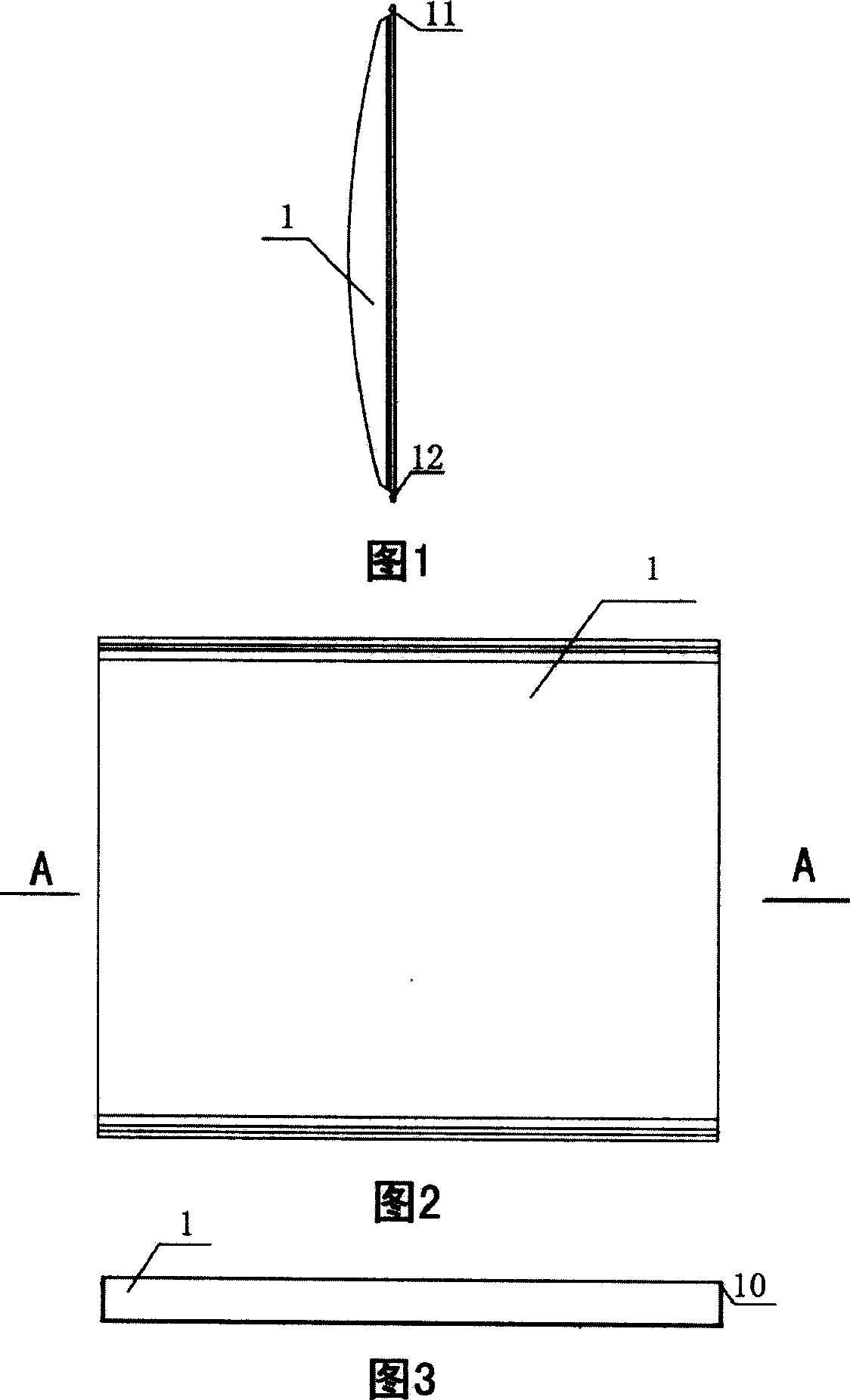

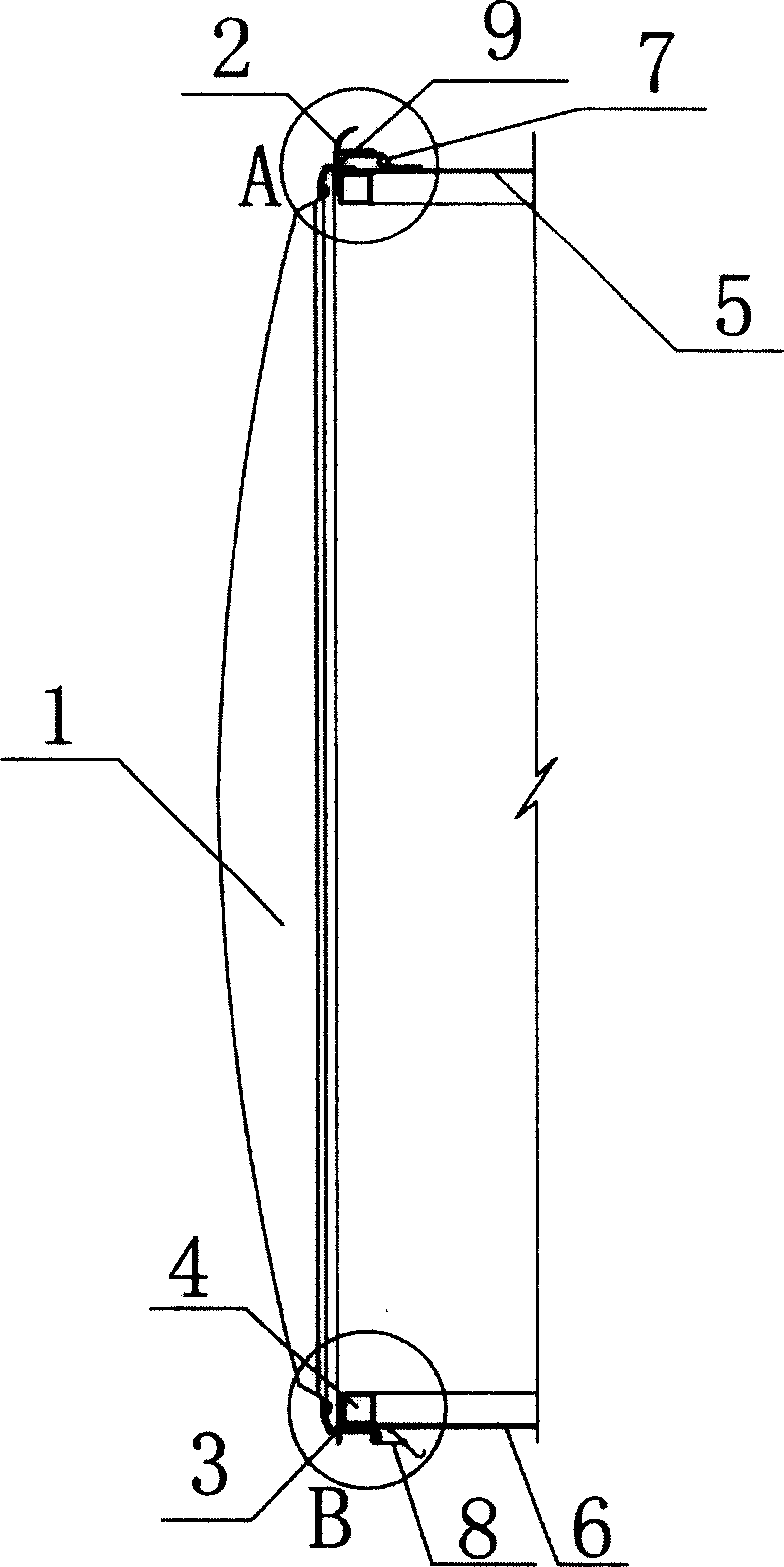

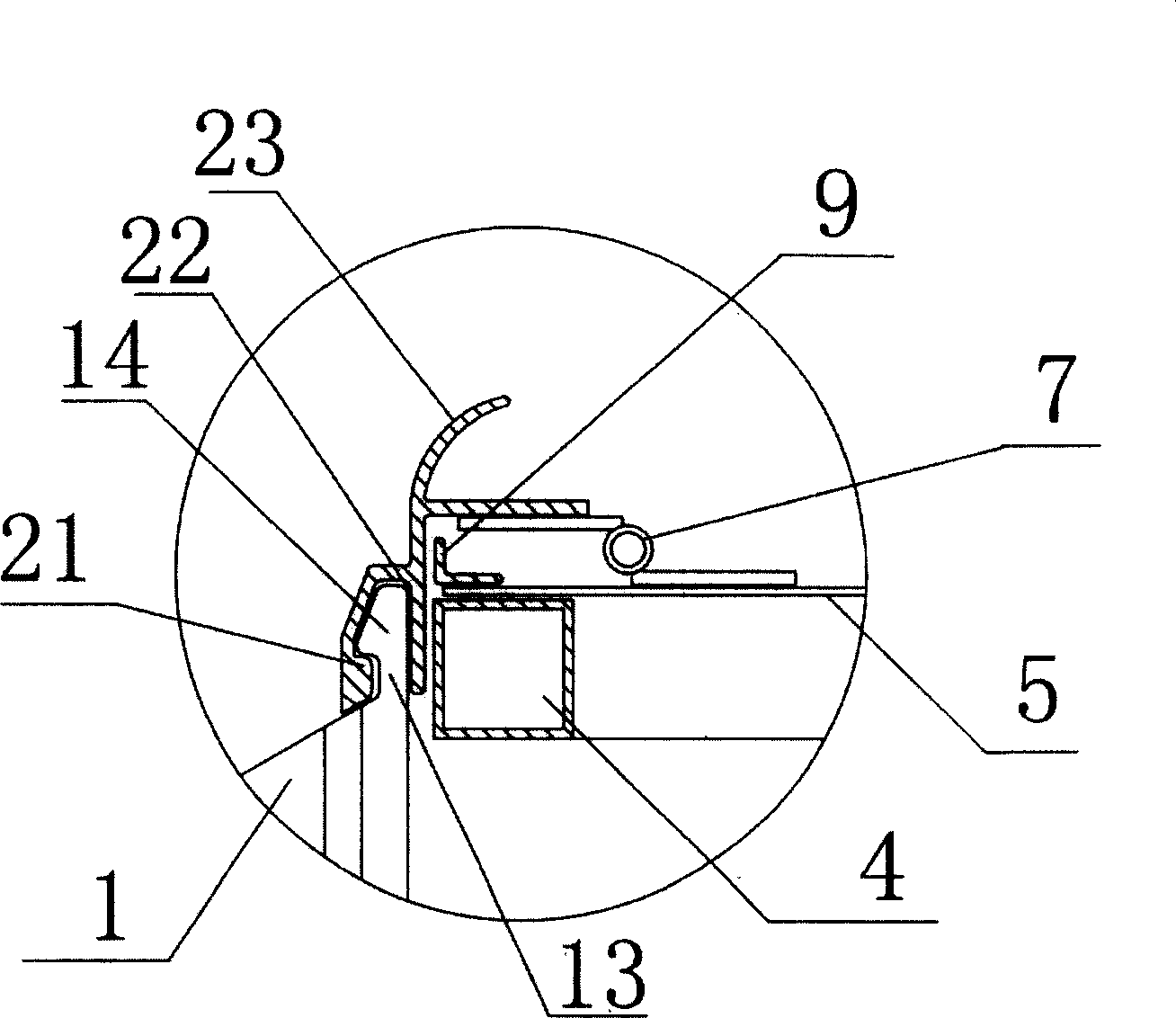

[0030] Referring to Figs. 1, 2 and 3 for the embodiment of the light box cover panel of the present invention, the left and right side edges of the light box cover panel 1 respectively have a dust-proof groove, and the groove is filled with a sealing strip 10. The front plate surface is a convex arc surface, the rear plate surface is a plane, the upper edge of the plate body has an upper load-bearing hook 11, the lower edge of the plate body has a lower load-bearing hook 12, and the head 14 of the load-bearing hook The neck 13 of force hook head expands. The back of the upper and lower load-bearing hooks is flush with the plate body, and the neck 13 front of the load-bearing hooks is concave. The neck 13 from the board body to the force-bearing hook gradually becomes thinner from the front of the board body to the rear direction of the board body. The lower jaw of the load-bearing hook head protrudes forward, the top of the head is flat, and an inclined slope is formed from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com