Method and apparatus for testing tunnel magnetoresistive effect element, manufacturing method of tunnel magnetoresistive effect element and tunnel magnetoresistive effect element

A technology of tunneling magnetoresistance and manufacturing method, which is applied in the manufacture/processing of electromagnetic devices, functional testing of magnetic heads, and the manufacture of magnetic flux-sensitive magnetic heads, etc., which can solve the problems of costing a lot of manpower and time, and achieve effective and fast mass production The effect of convenient and error-free confirmation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Before describing the preferred embodiments of the present invention, the relevant circumstances leading to the present invention will first be introduced.

[0054] The inventors of the present application found that when the sensing current flowing through the TMR read head element is increased to a value that may cause breakdown of the element, the TMR read head element dominated by metal conduction and the TMR read head element dominated by tunnel current There are differences in the resistance change characteristics of each TMR read head element among the head elements.

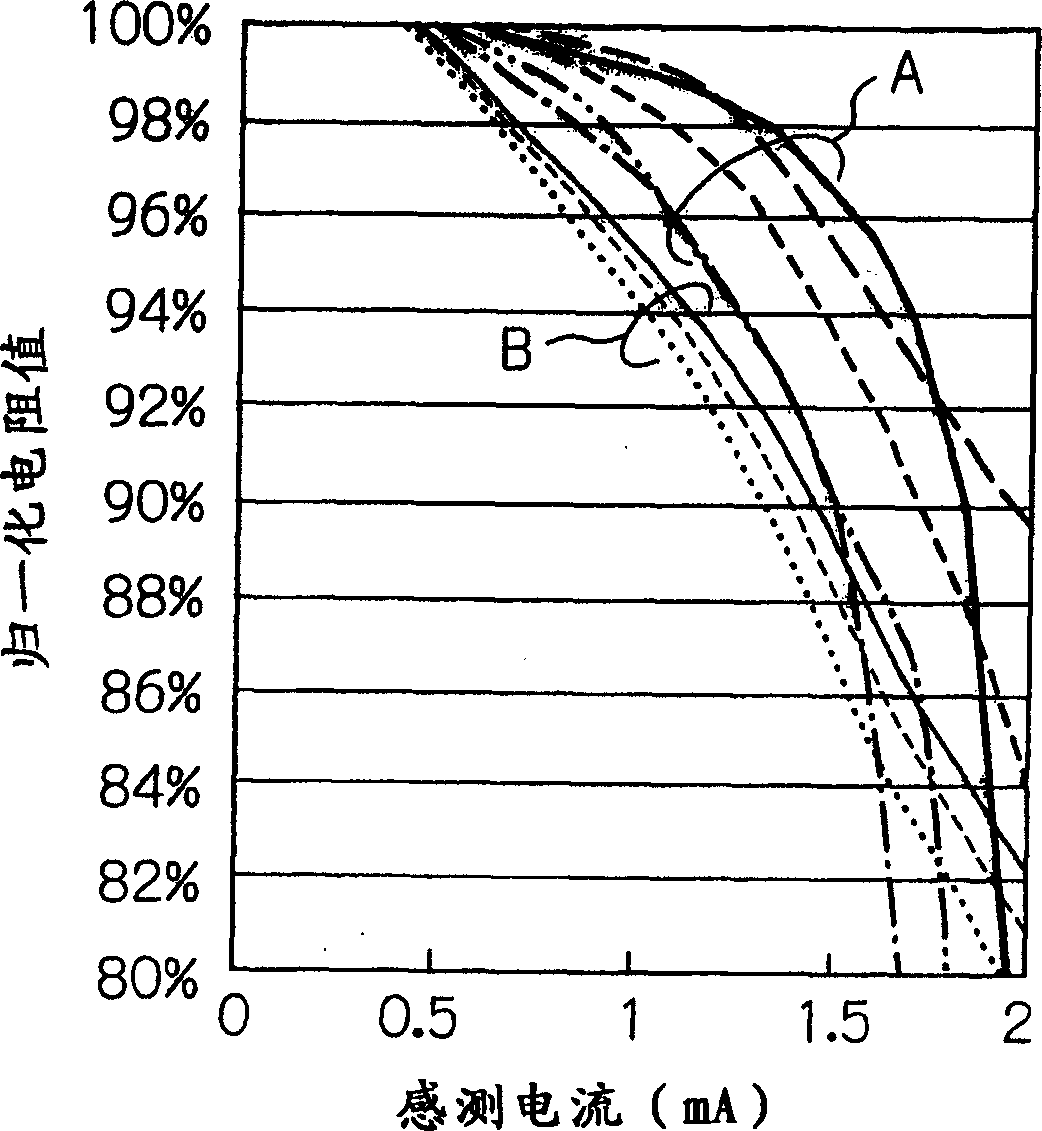

[0055] figure 1 shows the characteristic between the normalized resistance (%) and the sense current Is (mA) for a plurality of TMR read head elements measured by the present inventors.

[0056] As shown in the figure, it should be noted that there are two groups, that is, for group A TMR read head elements, when the sense current increases, its resistance gradually decreases, and for group B TMR ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com