Method for arranging electronic ballast in high strength gas discharge lamp

A technology of electronic ballasts and gas discharge lamps, which is applied in the direction of circuit layout, components of lighting devices, cooling/heating devices of lighting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] One of the embodiments of the present invention:

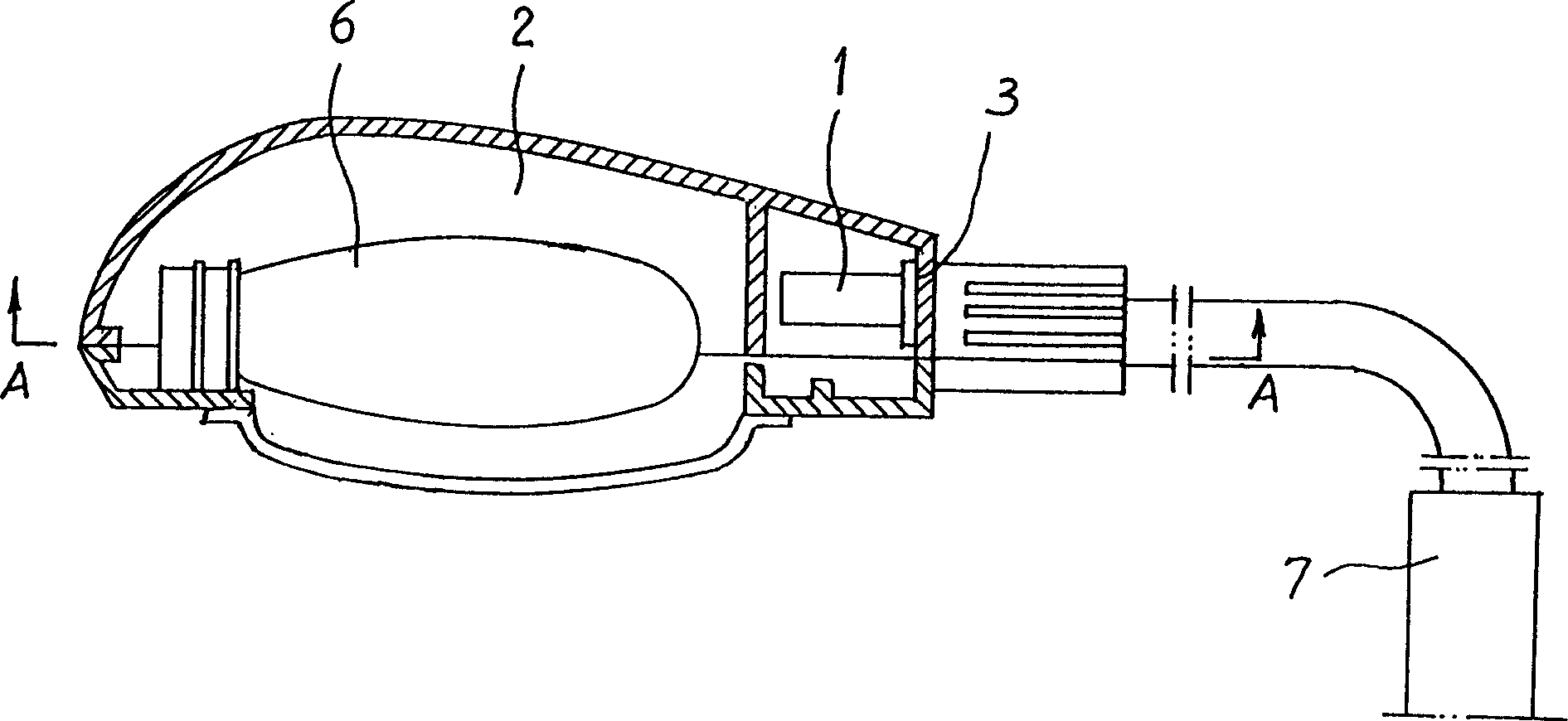

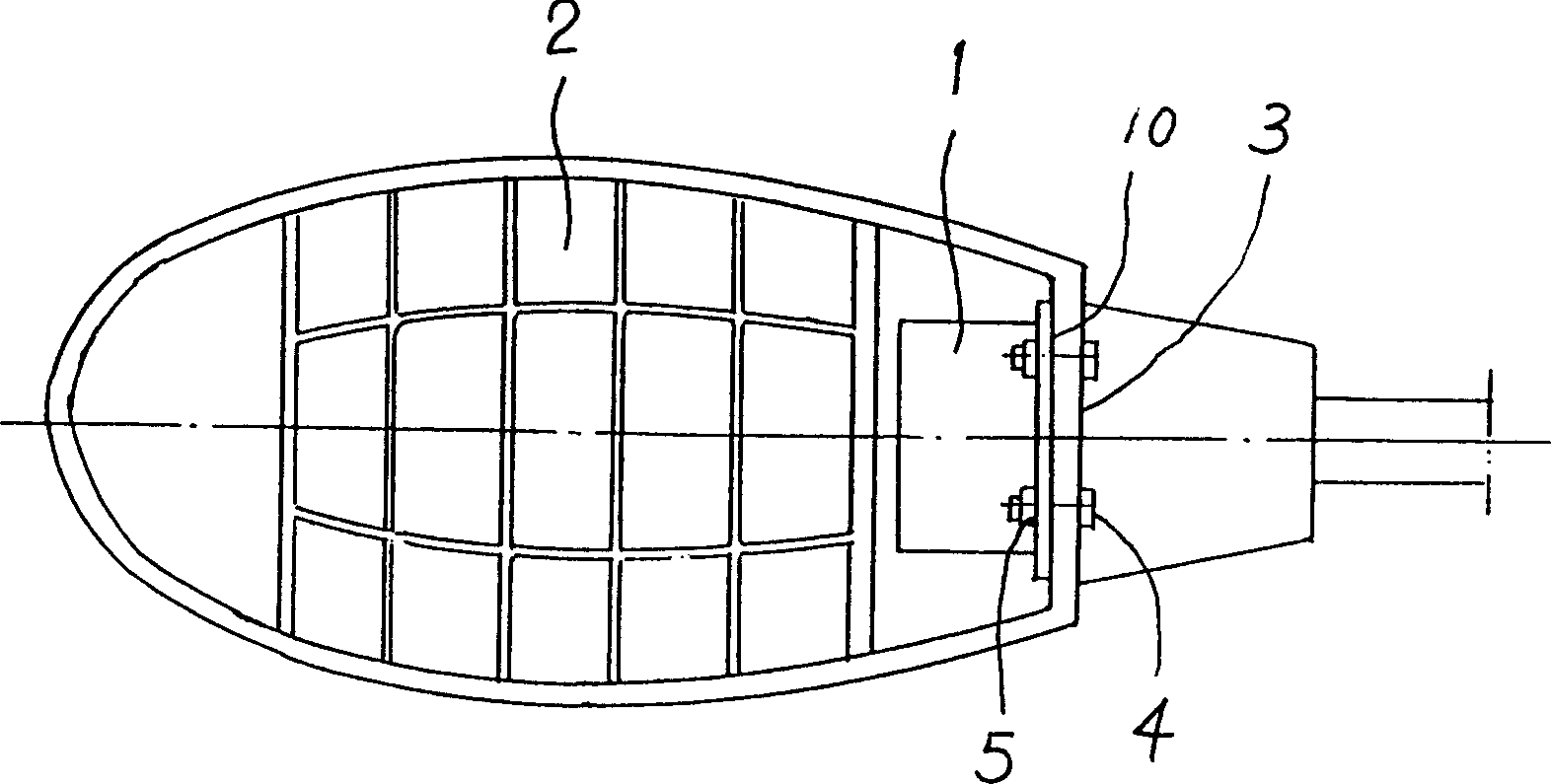

[0010] like Figure 1 to Figure 2 As shown, a plane of the electronic ballast 1 is placed on the inner surface of the rear wall 3 of the lamp housing 2, and finally the electronic ballast 1 is fastened to the inner surface of the rear wall 3 of the lamp housing 2 by bolts 4 and nuts 5 just go up. 6 is a light bulb among the accompanying drawings, and 7 is a lamppost.

[0011] Another embodiment of the invention:

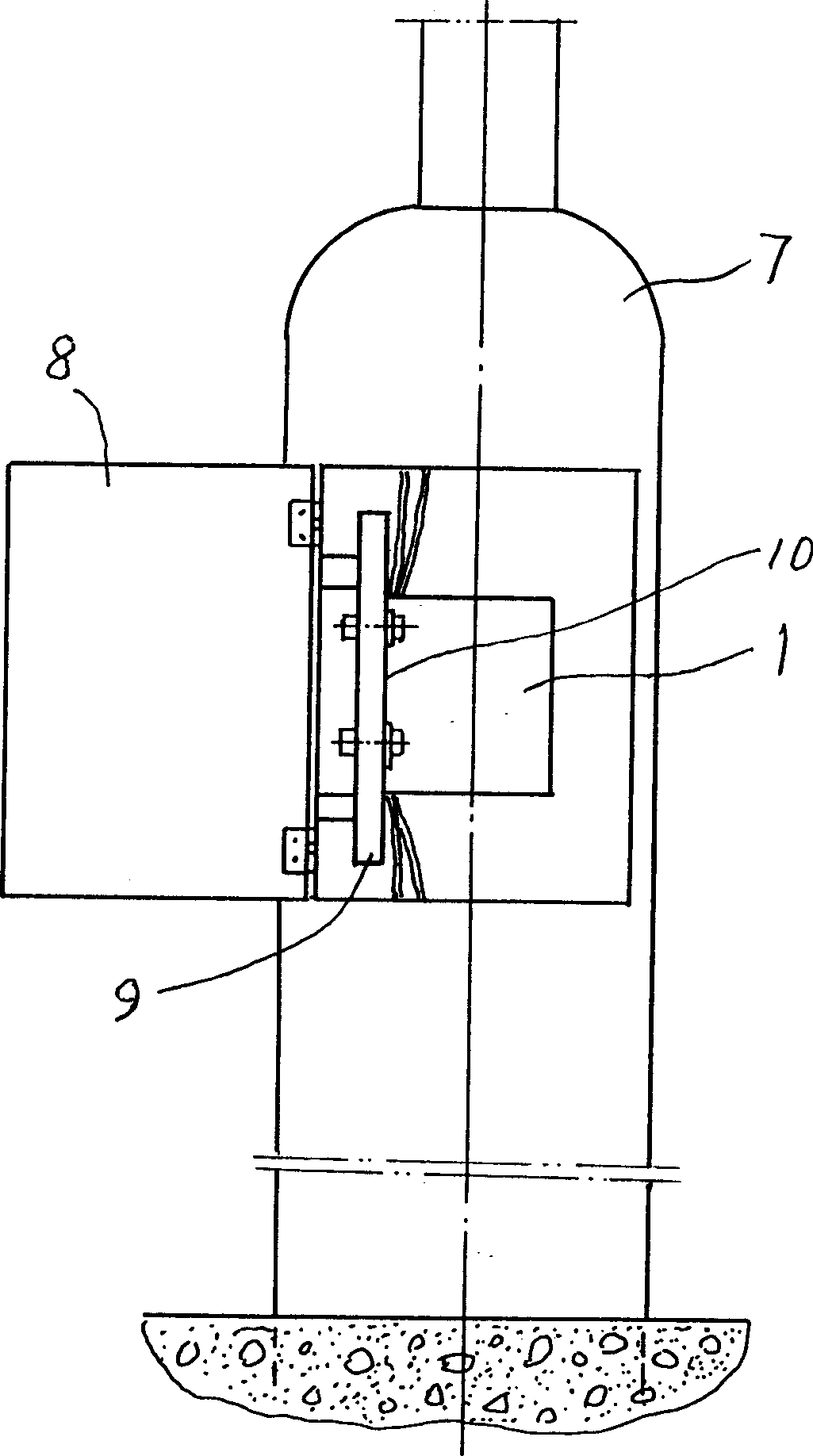

[0012] like image 3 The solution shown is to place a flat surface of the electronic ballast 1 on a flat plate 9 inside the lamp post door 8 at the lower part of the lamp post 7 for mounting fuses and other components.

[0013] During implementation, the largest plane of the electronic ballast 1 should be in contact with one of the planes of the lamp housing 2 or the lamp post 7 as much as possible, so as to expand the heat dissipation area and speed up the heat dissipation. In addition, in order to furth...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap