Dispensing and bale discharging computer control method in aluminium casting

A control method and computer technology, applied in the direction of calculation, casting equipment, manufacturing tools, etc., can solve problems such as calculation errors, broken furnaces, and the quality of finished aluminum that cannot be said to be accurate ingredients, so as to reduce the amount of tasks, concentrate the grade and be precise, Avoid illegibility and misreading effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A complete package scheduling model includes 12-16 packages per shift in each workshop, and a total of 24-32 packages in the two workshops. There are three shifts per day, namely the small night shift (16:00-24:00), the large night shift ( 0:00-8:00), day shift (8:00-16:00). Before 12:00 of each day shift, the team leader of the electrolysis team will send the task list to the foundry workshop, and the contractor in the foundry workshop will input the tank number and task quantity into the computer. While entering the tank number, the iron and silicon content of the tank Automatically retrieved from the database and displayed in the specified cell. After the task quantity of each package is input, the calculation of the average iron content, average silicon content and total weight of the package is automatically completed. After completing the input of all task quantities in a workshop, Automatically complete the calculation of the average iron content, average silicon...

Embodiment 2

[0044] Table 1 is a part of the primary aluminum quality input table. For example, today is April 5, and the contractor needs to input the primary aluminum quality of April 4 into the April 4 column.

[0045] time

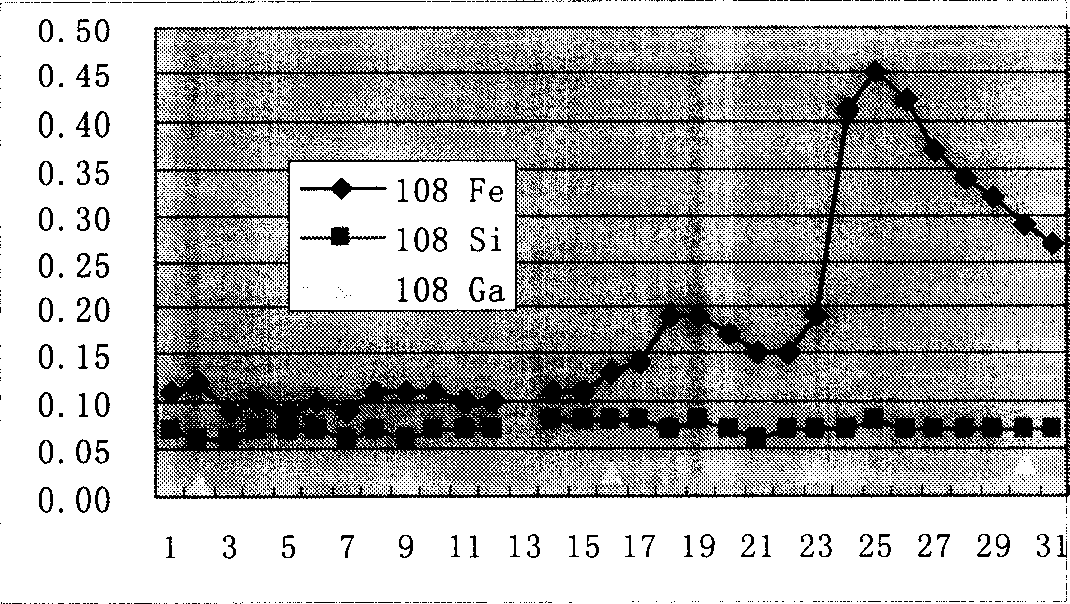

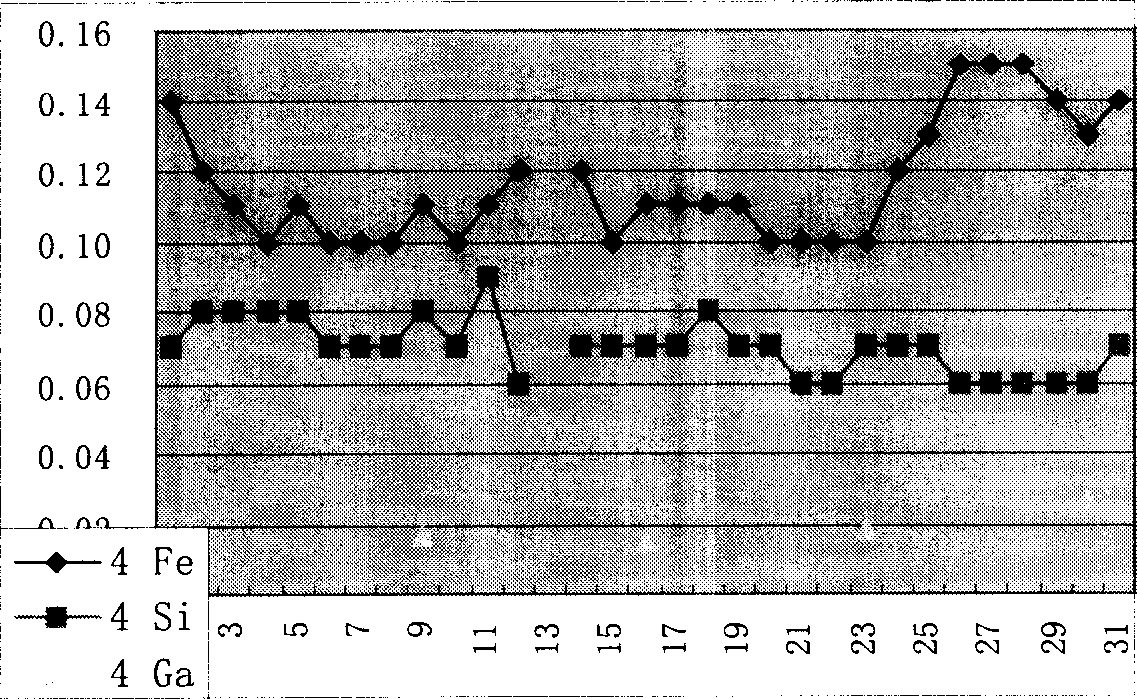

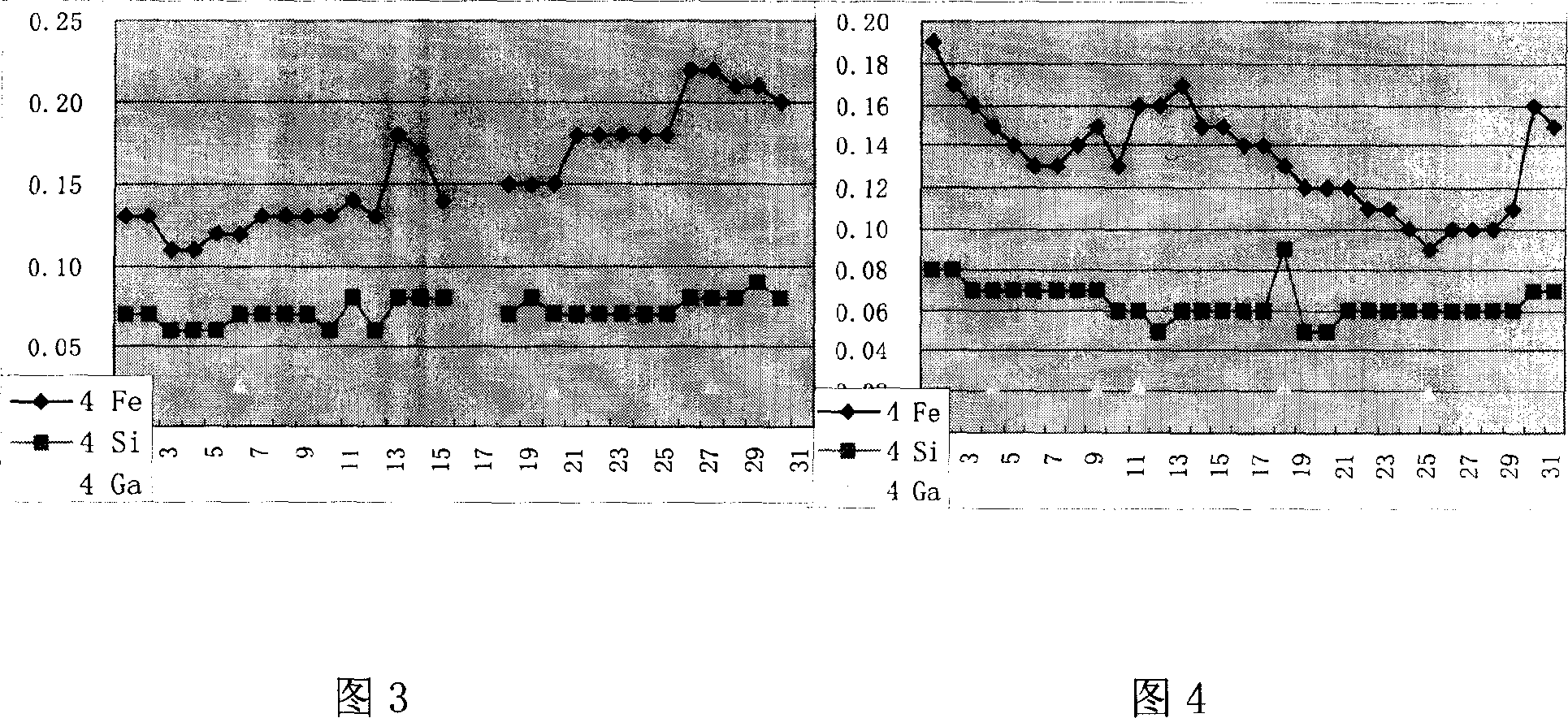

[0046] The quality of primary aluminum often changes suddenly. To grasp its change law, it is necessary to continuously check the change of primary aluminum quality for 3-5 days to determine, and thus design a dynamic change curve for one month, as shown in figure 1 shown.

[0047] It can be clearly seen from the figure that the iron content in the tank has a clear upward trend from the 13th to the 18th. The iron content of this trough rises sharply, so the trough should be predicted in the subsequent packing model between the 13th and 18th, and the predicted value should be set at an increase of 0.02% per day, and especially on the 22nd to 25th. On the 24th, a larger space for ingredients should be reserved. For example, consider setting the forecast v...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap