Recovering method of acetone and ammonia in hydrated hydrazine waste salt water by ketone azine method

A technology for recovering ketazine method and ketazine method, which is applied in the field of recovery and utilization of acetone and ammonia, which can solve the problems of loss and low yield of hydrazine, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

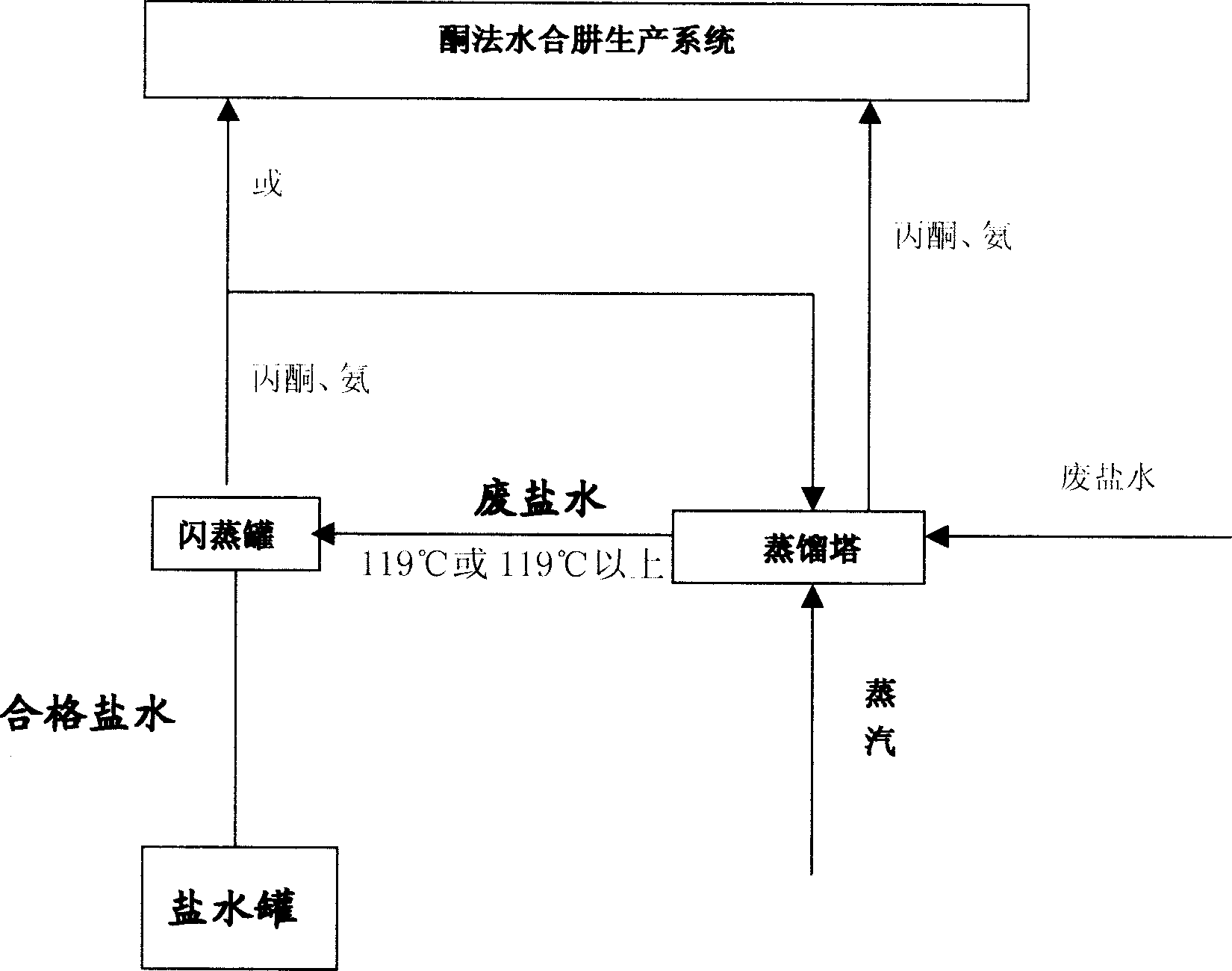

[0027] (a) The waste brine in the production process of hydrazine hydrate by ketazine method is continuously sent to the distillation tower, and the steam at 150°C is continuously and directly passed into the bottom of the distillation tower to make the waste brine form bubbling, and the steam flow rate is used to control the distillation tower The temperature at the top is 90°C, and the temperature of the waste brine reaches 119°C. The acetone and ammonia in the waste brine in the tower kettle are evaporated, and the ketazine, acetone, and ammonia separated from the waste brine are recovered through the top of the tower and used as ketazine hydration The raw material for hydrazine production is sent back to the hydrazine hydrate production system using the ketazine method; the remaining waste brine is sampled and analyzed, which contains sodium chloride: 6%, ketazine: 0.1%, ammonia: 0.1%, acetone: 0.1% It can be seen that a large amount of ketazine, acetone, and ammonia have b...

Embodiment 2

[0030] Reclaim acetone and ammonia in the ketazine method hydrazine hydrate waste brine by the method in embodiment 1, change the steam temperature into 180 DEG C in wherein (a) step, enter the remaining waste brine temperature of the flash tank to be 122 DEG C, in The acetone and ammonia recovered after (b) step flash evaporation are not directly returned to the ketazine method hydrazine hydrate production system to use, but enter (a) step distillation tower as a heat source for rectification recovery, and acetone and ammonia After concentration, it can be used as raw material for the production of hydrazine hydrate by the ketazine method, react with sodium hypochlorite to obtain ketazine, and then hydrolyze to obtain hydrazine hydrate. Finally, the remaining brine can also be configured as qualified brine to be used as a raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com