Production of mechanical hub rim seat and its shape steel bar material

A production method and technology of construction machinery, applied in the direction of a device in which the axial direction of the swirl can be reversed, a swirl device, etc., can solve the problems of wasting raw materials, wasting steel, wasting electric energy, etc., and achieve a simple production method and a reasonable shape Effect

Inactive Publication Date: 2006-03-15

王学田

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

a. Waste of raw materials, about 9 kg of steel is wasted to produce a part; b. Waste of labor; c. Waste of electricity; d. Consumption of tools

The reason for the correction is that the process is unreasonable and the shape of the spare material for producing the rim bead seat is unreasonable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

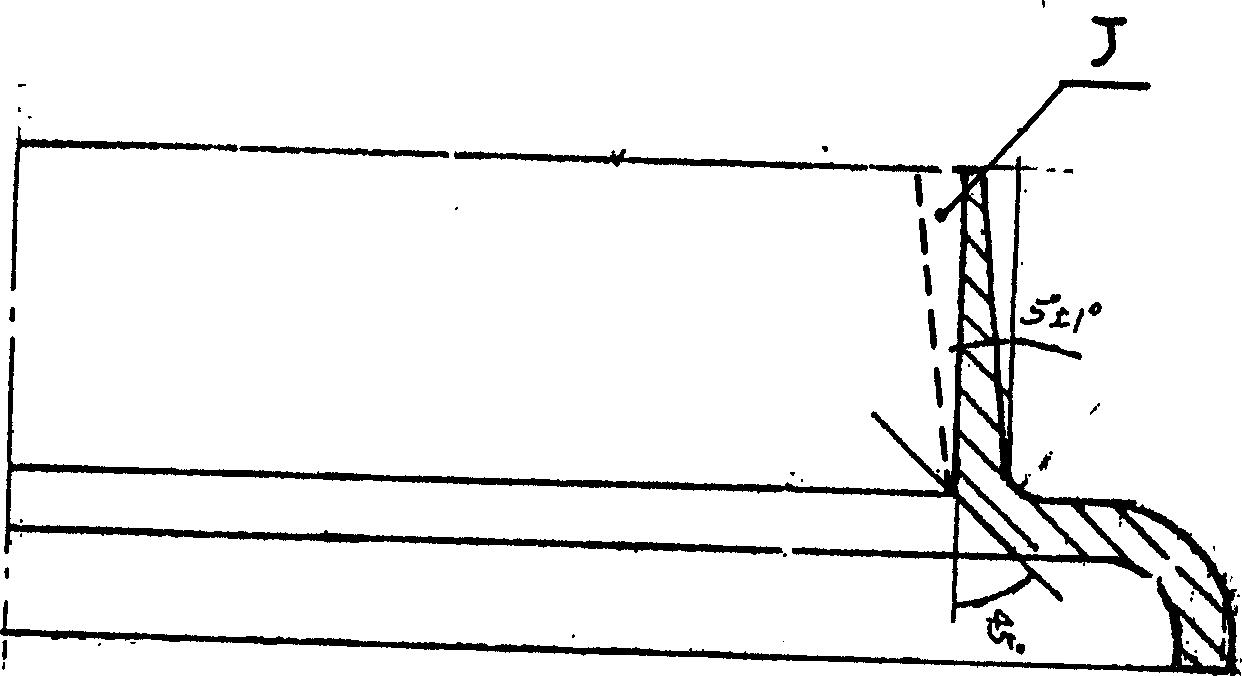

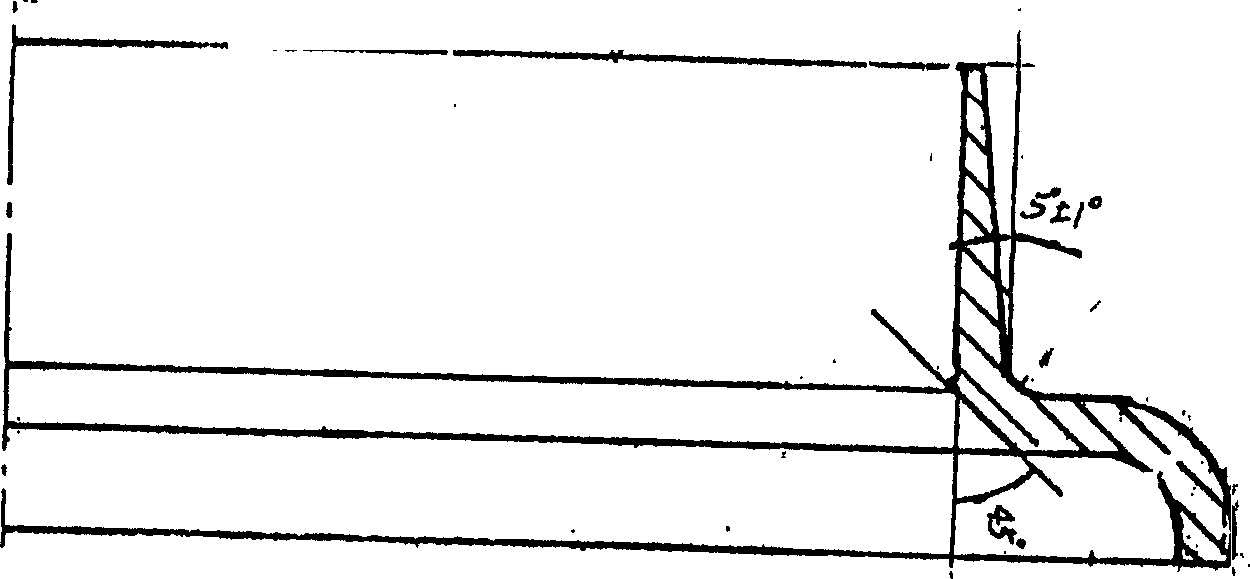

[0012] The production method of the present invention is a, prepare profiled steel strip material; B, profiled steel strip material is cut blanking according to required length; f. The lathe processes the 45° surface; g. The two ends of the lathe are finished.

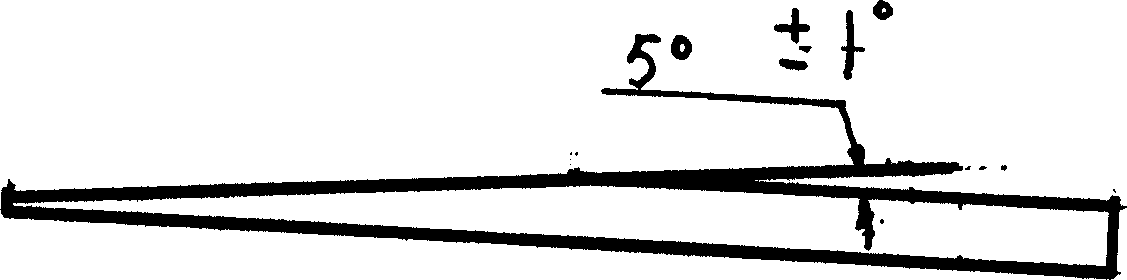

[0013] The upper left side of the prepared steel strip material of the present invention is a slope of 5°, and its tolerance is ±1°.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A technology for manufacturing the wheel rim as tyre holder of engineering machinery includes such steps as providing strip steel section, cutting short by required length, making bevel ends, forming a ring by die, heating for shaping, turning surface by 45 deg, and smoothing the connecting. Its strip steel section is also disclosed.

Description

1. Technical field: [0001] The invention relates to a production method of construction machinery components and production materials thereof, in particular to a production method of construction machinery wheel rim bead seats and section steel strip materials. 2. Background technology: [0002] At present, the production method of construction machinery wheel rim bead seat is complicated, and needs to go through the process of machining the inner circle on a lathe, that is, the inner circle has a processed surface, so the production method has the following defects. a. Waste of raw materials, about 9 kg of steel is wasted to produce a part; b. Waste of labor; c. Waste of electric energy; d. Consumption of tools. The reason for the correction is that the process is unreasonable and the shape of the spare material for producing the rim bead seat is unreasonable. This is [0003] Insufficiency of existing technology. 3. Contents of the invention: [0004] The purpose of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23P13/00B04C5/08

Inventor 王学田

Owner 王学田

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com