Cloth feeding device for sewing machine

A technology of a cloth feeding device and a sewing machine, which is applied in the direction of sewing machine components, cloth feeding mechanisms, sewing equipment, etc., and can solve problems such as inability to correctly transport the sewn object and the error of the cloth feeding amount, so as to save setting space, suppress jumping, The effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0050] (overall structure of the embodiment of the present invention)

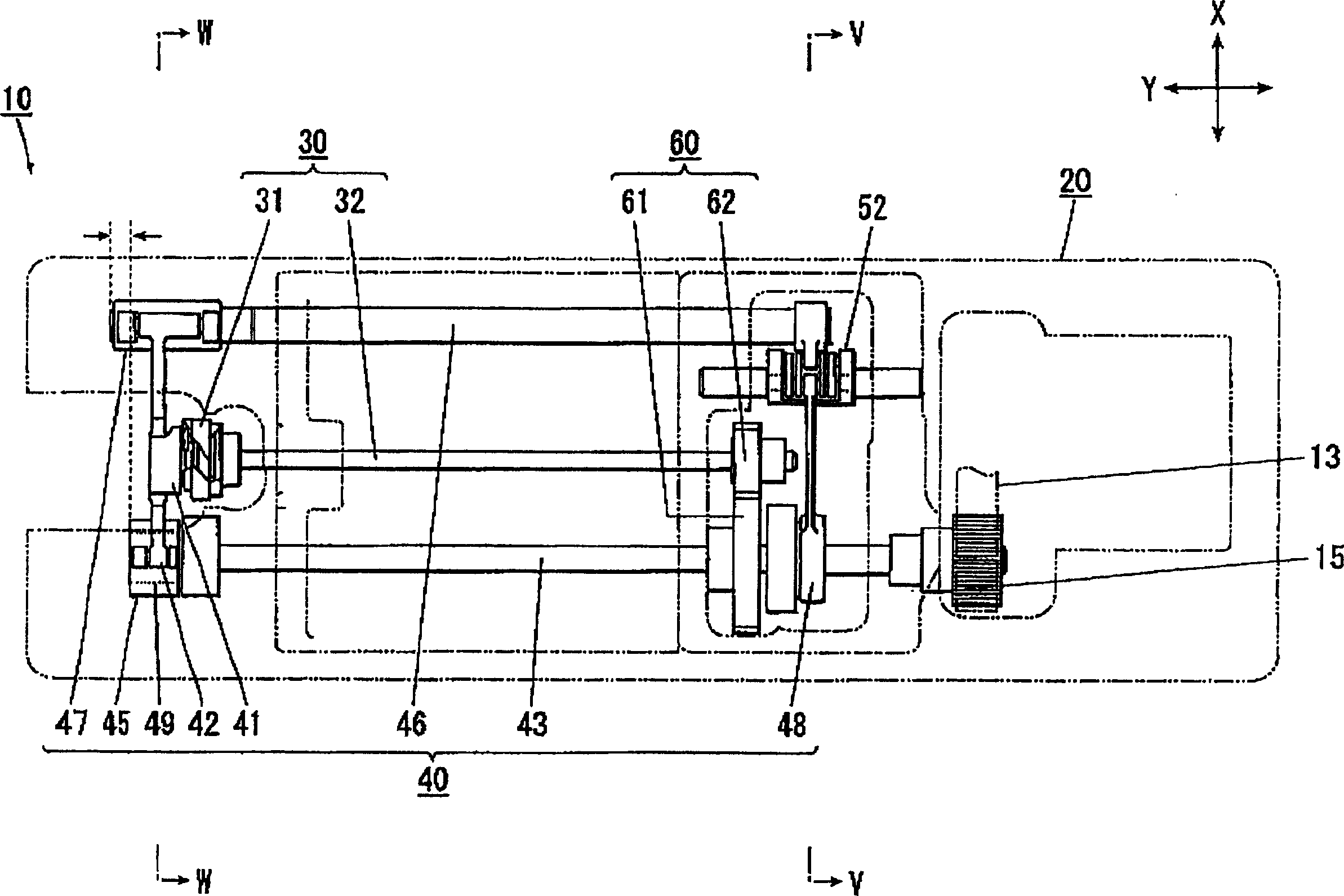

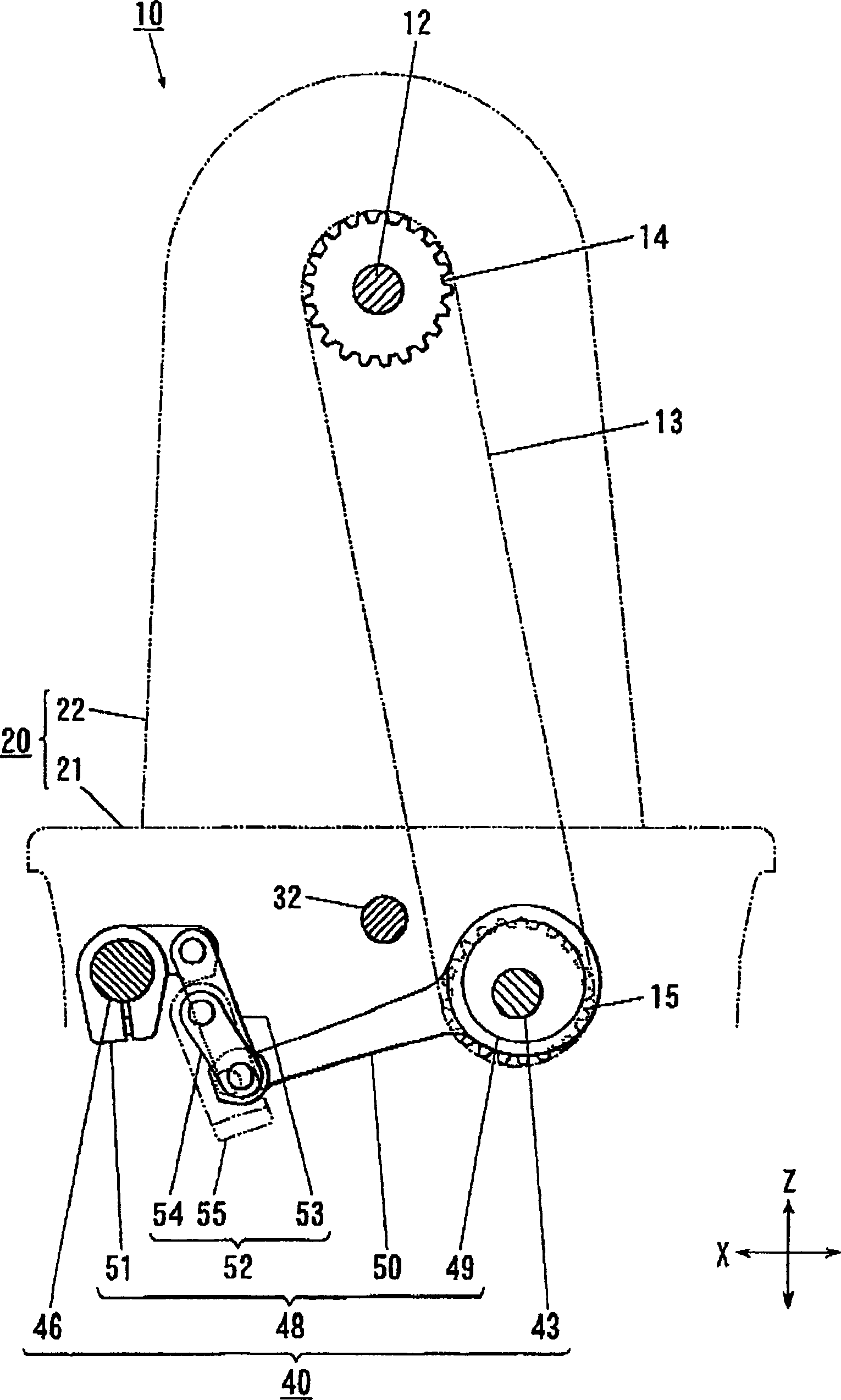

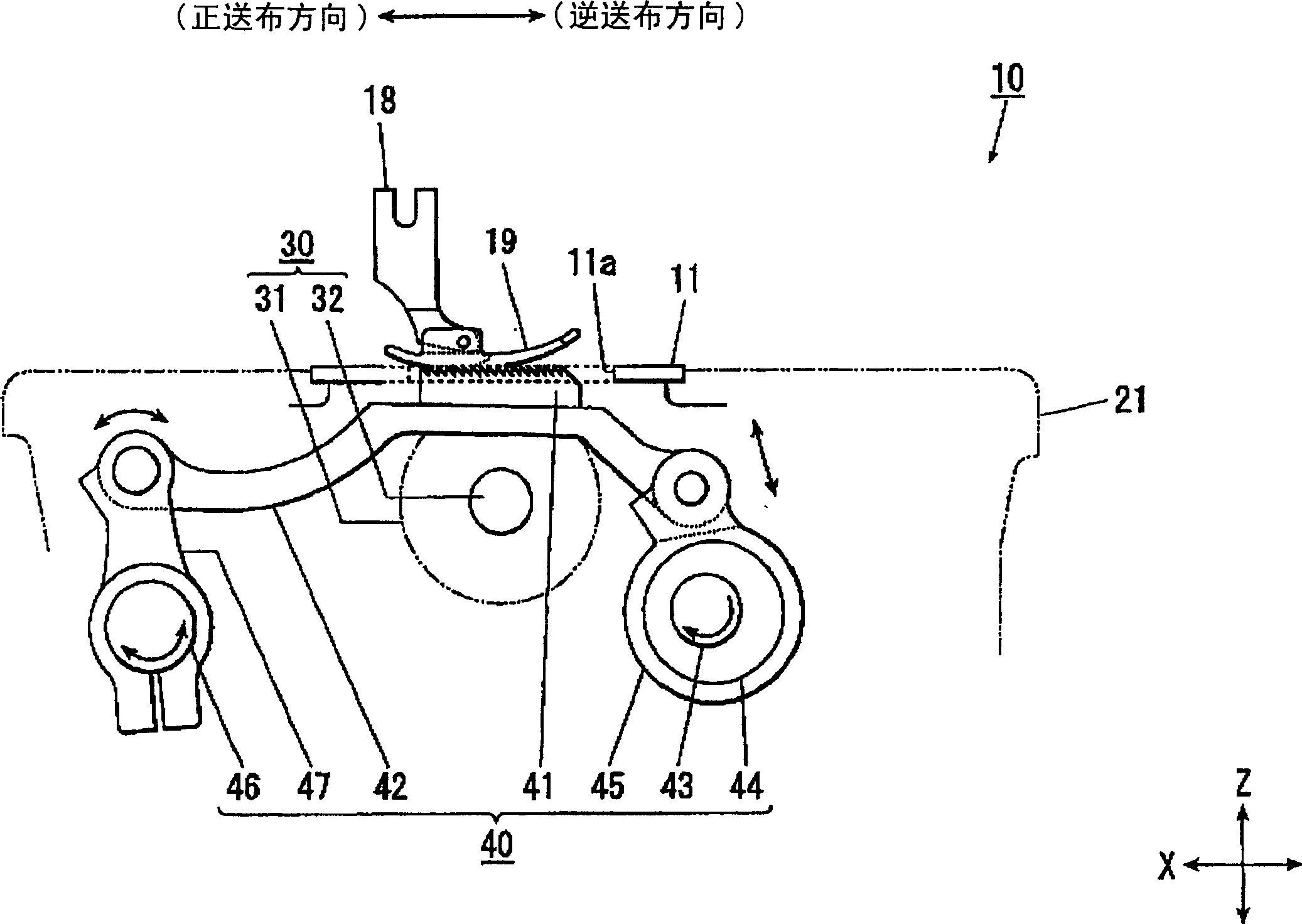

[0051] Below, refer to Figure 1 to Figure 5 Embodiments of the present invention will be described in detail. figure 1 It is a structural diagram of only the main structure of the sewing machine 10 according to the embodiment of the present invention, which will be described later in the bottom plate portion 21. figure 2 yes figure 1 The cross-sectional view along the line V-V in, image 3 yes figure 1 A cross-sectional view along the line W-W in .

[0052] The above-mentioned sewing machine 10 has: an unillustrated vertical movement mechanism for moving the machine needle up and down, an unillustrated sewing machine motor as its driving source, and a suture thread that winds the bobbin thread around the suture thread passing through the machine needle through the full rotary hook 31. The rotary hook mechanism 30 in the middle, the cloth feeding device 40 that is consistent with the up and down m...

no. 2 example

[0110] Next, a second embodiment of the present invention will be described. In addition, in this embodiment, the same symbols are used for the same structures as those of the above-mentioned first embodiment, and repeated description thereof will be omitted.

[0111] On the sewing machine 100 of this embodiment, the difference from the above-mentioned sewing machine 10 is that the other end of the upper and lower cloth feeding shaft 430 with the pulley 15 installed at one end, and the front end, that is, the cloth feeding seat 420 of the upper and lower cloth feeding shaft 430 The end portion on the side is located on the side of the vertical body 22 than the end portion on the opposite side of the vertical body 22 of the full rotary hook 31 (refer to Figure 9 ). which is, Figure 9 The shown upper and lower feed shaft 430, the end of the cloth feed seat 420 side, is located at Figure 9 on the right side of the full rotary hook 31 left end. In addition, the cloth feed s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap