Gas well separate layer fracturing and producing integrated well completing pipe string and technique

A technology for layered fracturing and well completion strings, which is applied in the direction of production fluid, wellbore/well components, drill pipe, etc., which can solve the problems of reservoir damage, complicated construction, high construction cost, etc., and achieve fast liquid drainage, The effect of small tubing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

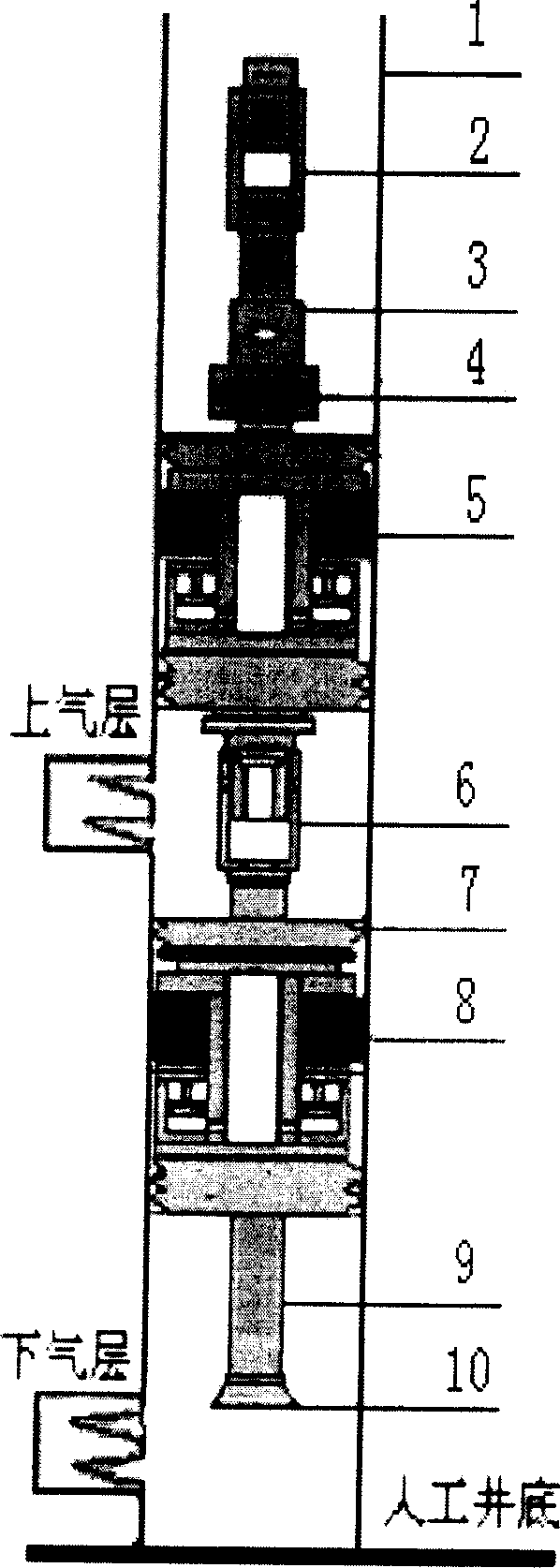

[0017] As shown in the figure, 1-casing, 2-pipe string telescopic compensator, 3-well cleaning switch, 4-safety joint, 5-upper washable well packer, 6-sand blasting sliding sleeve, 7-hydraulic anchor , 8-down washable packer, 9-tubing, 10-ball seat.

[0018] The present invention starts from the idea of running a set of operation strings into the well to complete layered fracturing and combined layer exploitation. Device 2, tubing 9, well flushing switch 3, safety joint 4, upper flushable packer 5 (with hydraulic anchor 7), sandblasting sliding sleeve 6, lower flushable packer 8 (with hydraulic anchor 7) , oil pipe 9, ball seat 10, etc. are combined from top to bottom, and the conventional pipe string telescopic compensator 2 is used to push the piston upward by hydraulic pressure to cut the shear nails during construction, release the elastic connection limit, and the pipe string telescopic compensator is in the pipe Under the action of string tension, the inner and outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com