Desulfurizing adsorption tower

A desulfurization absorption tower and absorption tower technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems such as the breakdown of the booster fan, economic loss, air pollution, etc., to ensure smooth progress and avoid economical problems. Loss and pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

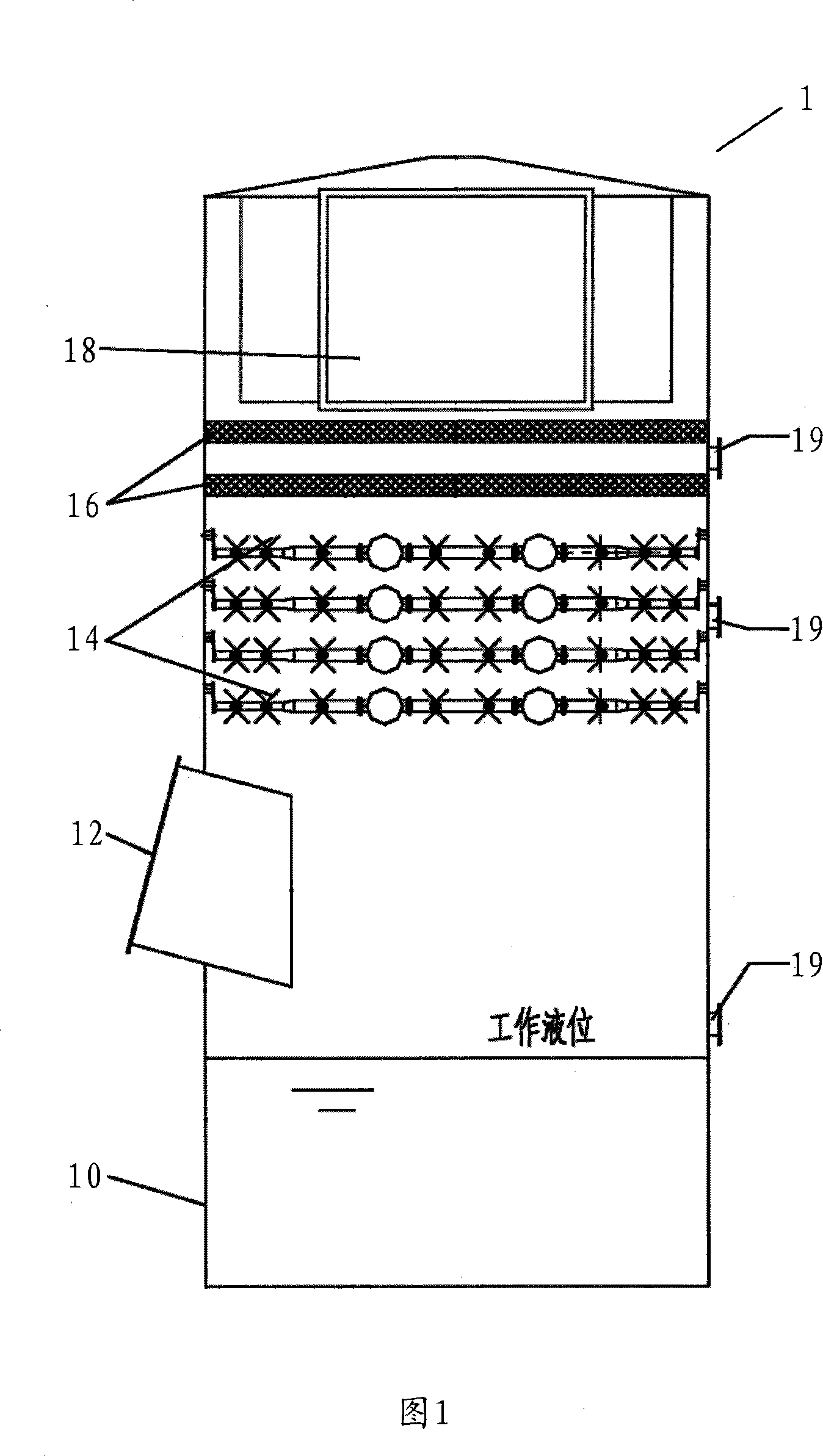

[0021] Please refer to Fig. 1, the desulfurization absorption tower 1 of the present invention is used for the wet method flue gas desulfurization of thermal power enterprise, comprises absorption tower body 10, is arranged on the original flue gas inlet 12 of this absorption tower body 10 middle and lower parts, is arranged on the absorption tower The slurry spray layer 14 in the upper part of the body 10, the mist eliminator 16 arranged above the slurry spray layer 14, the net flue gas outlet 18 arranged at the top of the absorption tower body 10 and the working liquid level ( Limestone, gypsum slurry), the observation device 19 arranged correspondingly to the slurry spray layer 14 and the demister 16.

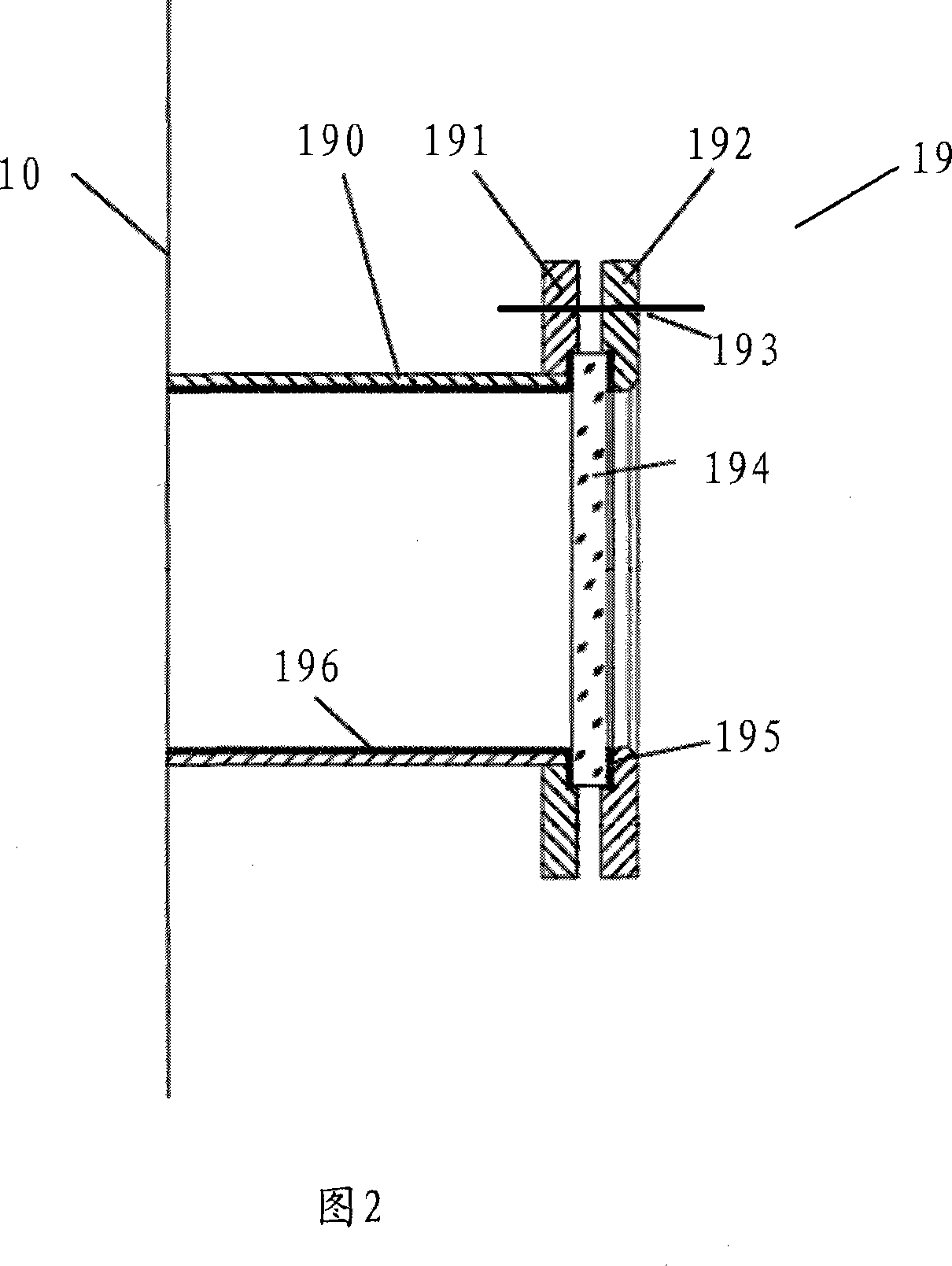

[0022] For the present invention, its improvement is mainly in its added observation device 19, and for other parts, it is basically the same as the structure of the previous desulfurization absorption tower, so the description of the same part is omitted here, and the emphas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com