Method for recycling waste power lithium battery positive electrode material through antibiotic mushroom dreg auxiliary heat treatment

A technology of antibiotic bacteria slag and positive electrode materials, applied in battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of loss of value and high production cost, achieve rich pore structure, good electrochemical performance, and realize harmless The effect of high-value/high-value disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

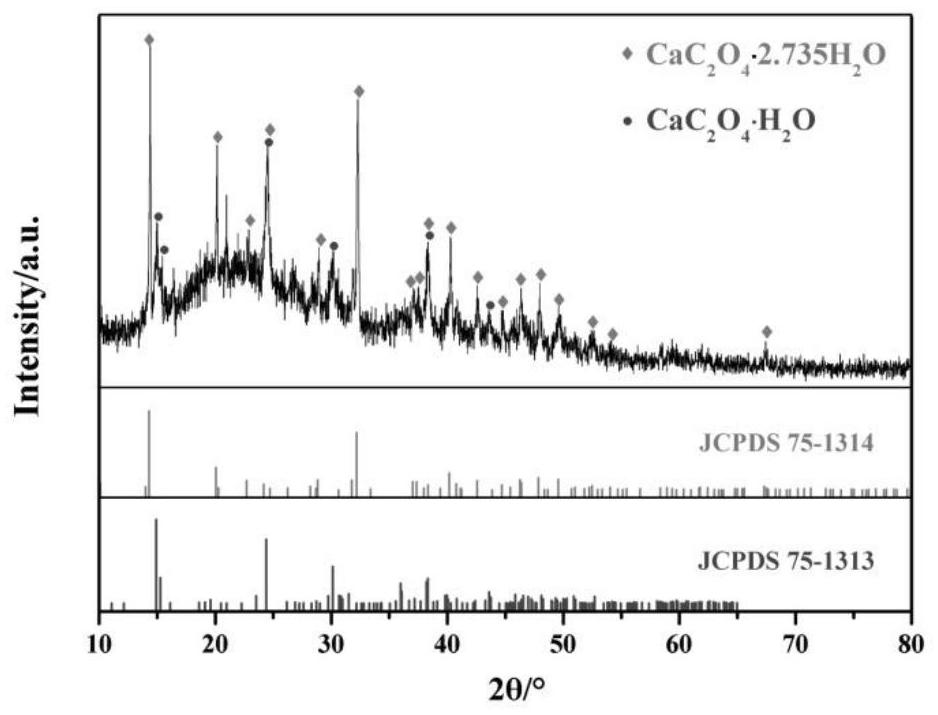

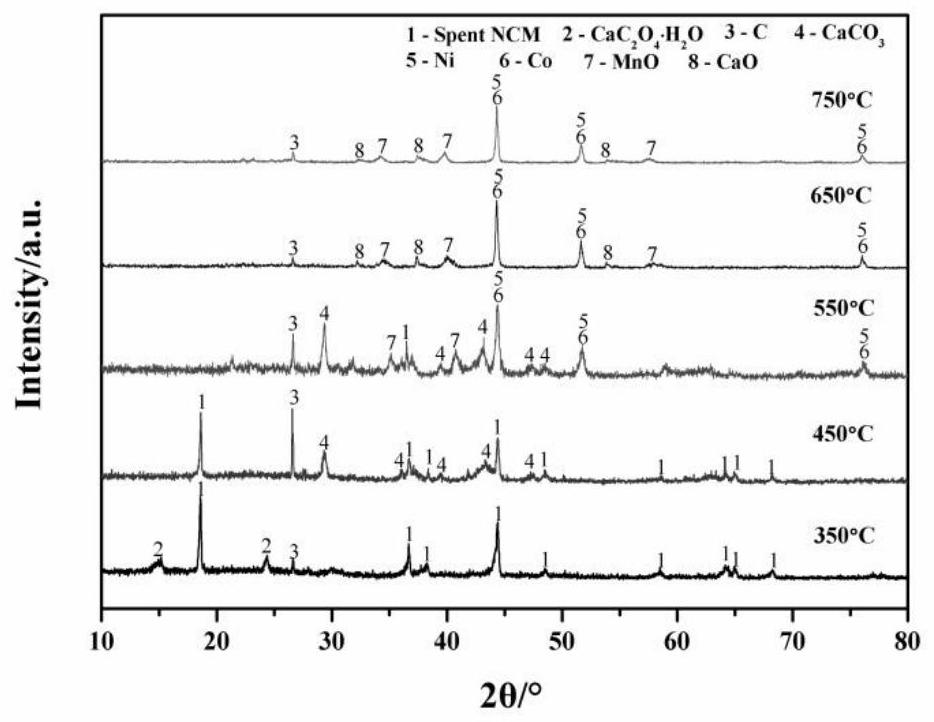

[0050] ①Auxiliary roasting: the solid waste produced in the antibiotic production process is antibiotic slag, and 4.0g of antibiotic slag (containing 15.5% calcium oxalate) and 2.0g of waste nickel cobalt lithium manganate are ground evenly in a mechanical grinder, and placed Roast at 650°C for 1 hour in a tube furnace with an inert atmosphere (referring to Ar gas), and obtain auxiliary roasting slag (also called calcined sand) after cooling;

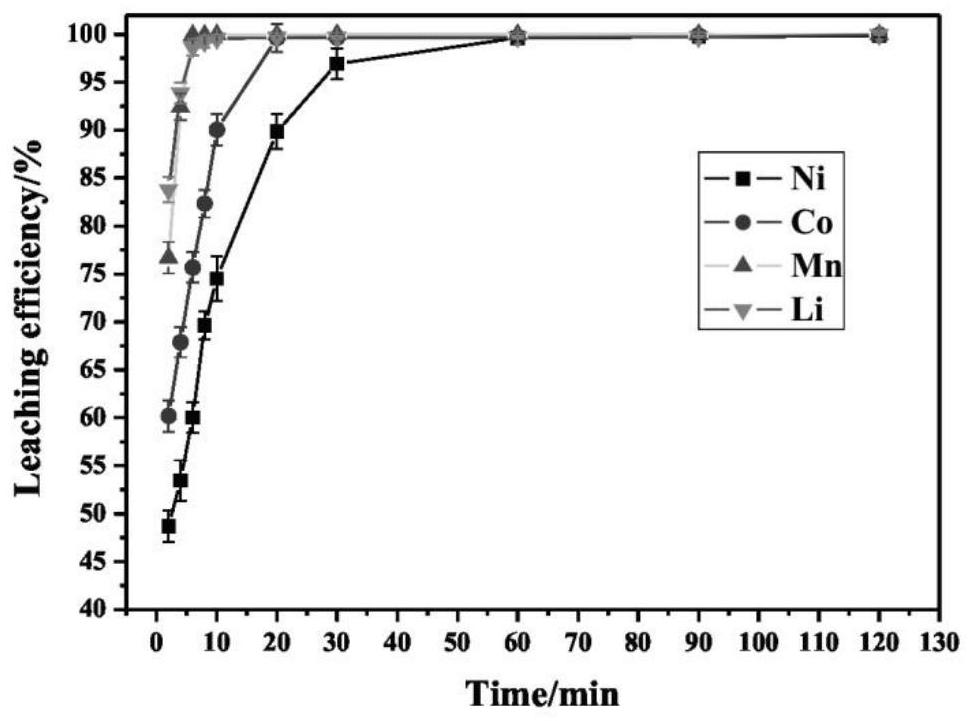

[0051] ②Low-acid acid leaching: first add 40mL of 1mol / L sulfuric acid solution into a beaker, heat and stir in a 60°C water bath for 20min, add auxiliary roasting slag at a liquid-solid ratio (mL:g) of 20:1, After continuing to stir and react for 3h, filter and wash to obtain pickling solution and pickling residue;

[0052] ③Reuse of antibiotic residues: wash the acid leaching residues with deionized water until the filtrate is neutral, and then directly obtain carbon materials derived from antibiotic residues after drying, without add...

Embodiment 2

[0055] ①Auxiliary roasting: The solid waste produced in the antibiotic production process is antibiotic slag, 3.0g of antibiotic slag (containing 17.3% calcium oxalate) and 1.0g of waste nickel cobalt lithium manganate are ground evenly in a mechanical grinder, and placed Roast at 750°C for 2 hours in a tube furnace with an inert atmosphere, and obtain auxiliary roasted slag after cooling;

[0056] ②Low-acid acid leaching: First, add 50mL of 1.6mol / L hydrochloric acid solution into a beaker, heat and stir in a water bath at 80°C for 20min, and add auxiliary roasting slag at a liquid-solid ratio (mL:g) of 30:1 , after continuing to stir and react for 2h, filter and wash to obtain pickling solution and pickling residue;

[0057] ③Reuse of antibiotic residues: wash the acid leaching residues with deionized water until the filtrate is neutral, and then directly obtain carbon materials derived from antibiotic residues after drying, without additional processing procedures, and perf...

Embodiment 3

[0060] ①Auxiliary roasting: The solid waste produced in the antibiotic production process is antibiotic slag. Grind 4.0g of antibiotic slag (containing 18.1% calcium oxalate) and 1.0g of waste lithium nickelate in a mechanical grinder evenly, and place them in an inert In a tube furnace with atmosphere, roast at 650°C for 1.5h, and obtain auxiliary roasting slag after cooling;

[0061] ②Low-acid acid leaching: First, add 50 mL of 1.2 mol / L nitric acid solution into a beaker, heat and stir in a water bath at 60°C for 20 minutes, and add auxiliary roasting slag at a liquid-solid ratio (mL:g) of 40:1 , after continuing to stir and react for 1h, filter and wash to obtain pickling solution and pickling residue;

[0062] ③Reuse of antibiotic residues: wash the acid leaching residues with deionized water until the filtrate is neutral, and then directly obtain carbon materials derived from antibiotic residues after drying, without additional processing procedures, and perform physical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com