Fuel jet valve

A fuel injection valve, fuel flow technology, applied in the direction of fuel injection device, special fuel injection device, charging system, etc., can solve the problems of expensive fuel injection valve, peeling off, expensive processing, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

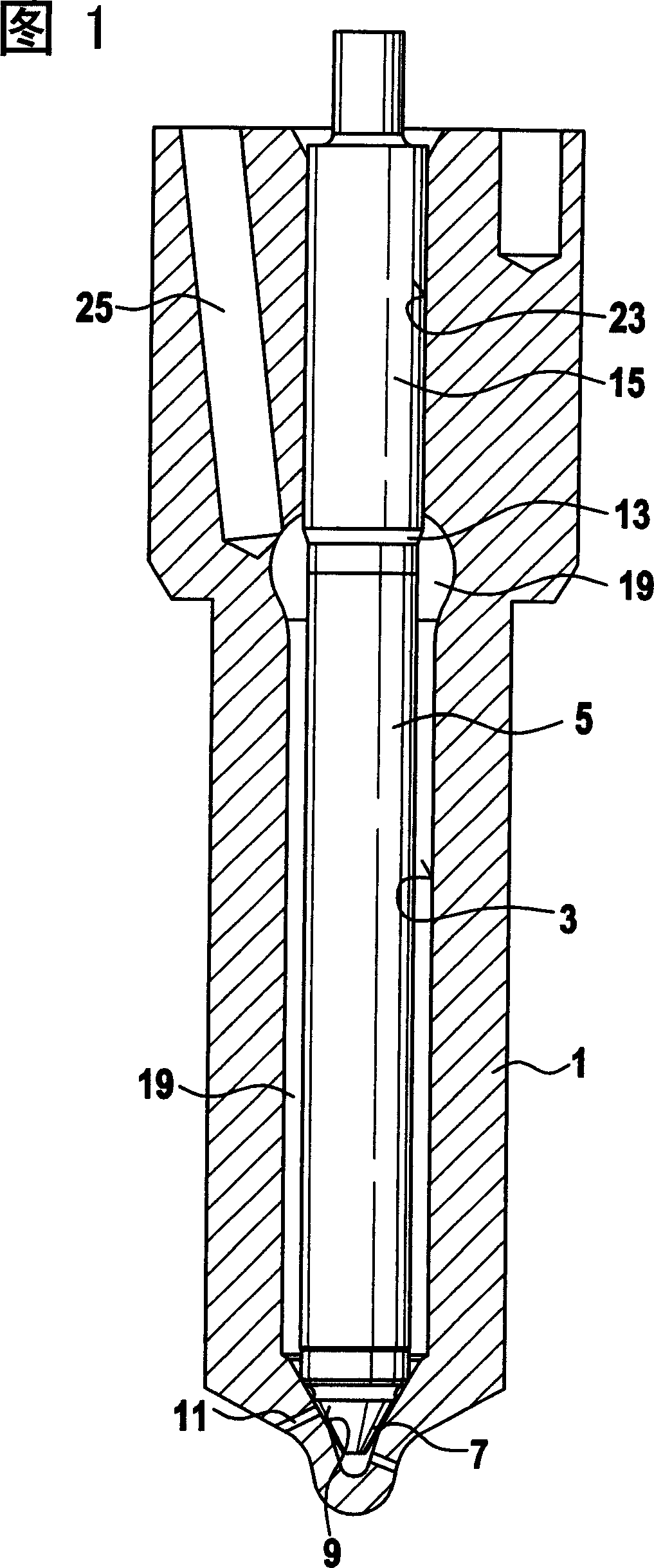

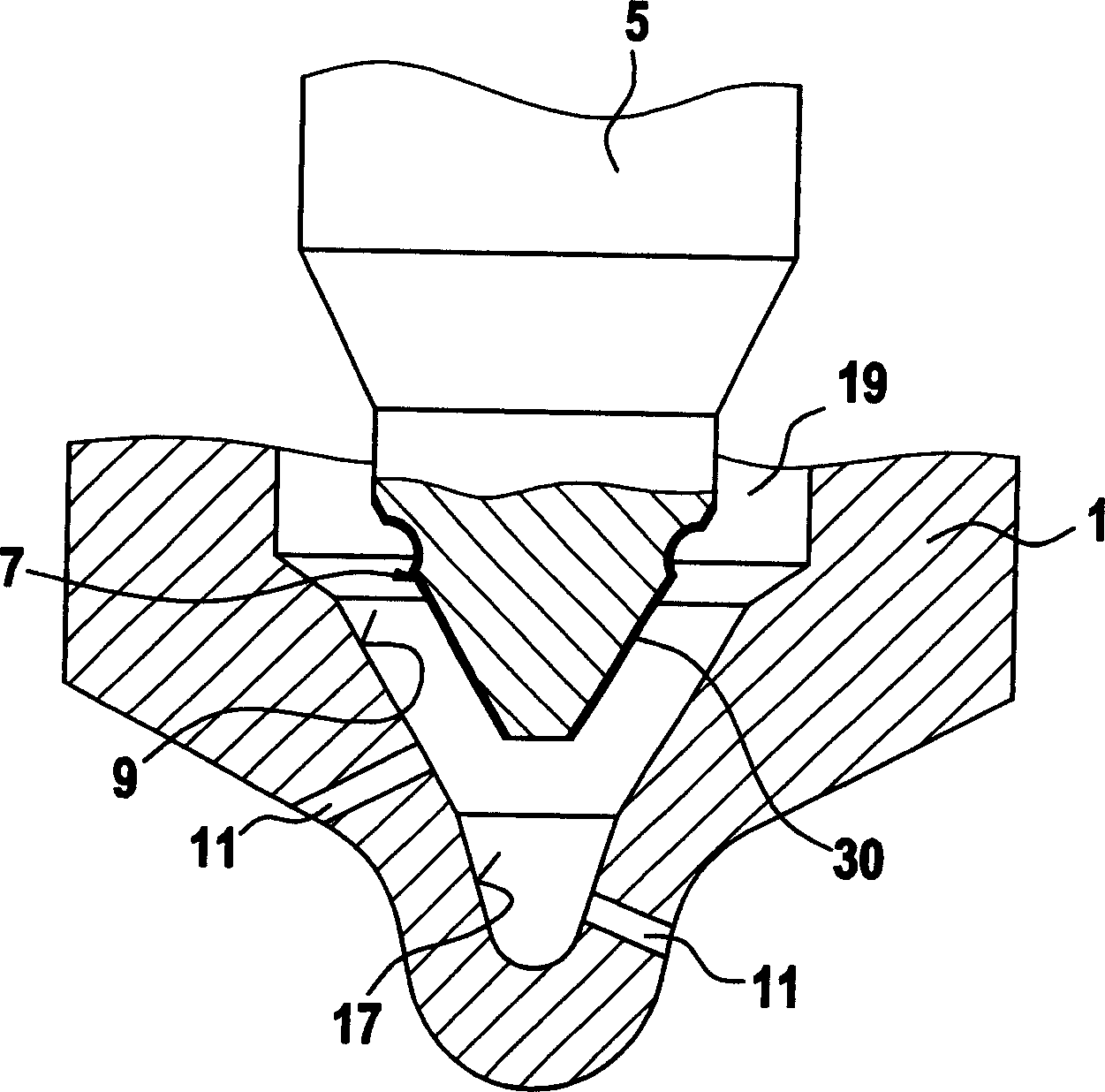

[0016] FIG. 1 shows a longitudinal section through a fuel injector according to the invention. A bore 3 is formed in the valve body 1 and is bounded at its combustion chamber-side end by an essentially conical valve seat 9 . One or more injection openings 11 lead from the valve seat 9 , which open into the combustion chamber of the internal combustion engine in the installed position of the fuel injection valve. A piston-like valve needle 5 is arranged longitudinally displaceable in the bore 3 , which is guided sealingly by a guide section 15 facing away from the valve seat 9 in a guide region 23 of the bore 3 . Starting from the guide section 15 , the valve needle 5 tapers in the direction of the valve seat 9 to form a pressure shoulder 13 and transitions at its end facing the valve seat 9 into an essentially conical valve sealing surface 7. The bore 3 widens radially at the level of the pressure shoulder 13 and forms a pressure chamber 19 which surrounds the valve needle 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com