Multi-directional control method and apparatus for laser power of CD-ROM

A technology of laser power and control method, applied in the direction of recording/reproducing by optical method, optical recording/reproducing/erasing method, beam source, etc. Responding to the width and narrowness of the disc track, etc., to avoid the effect of burning failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

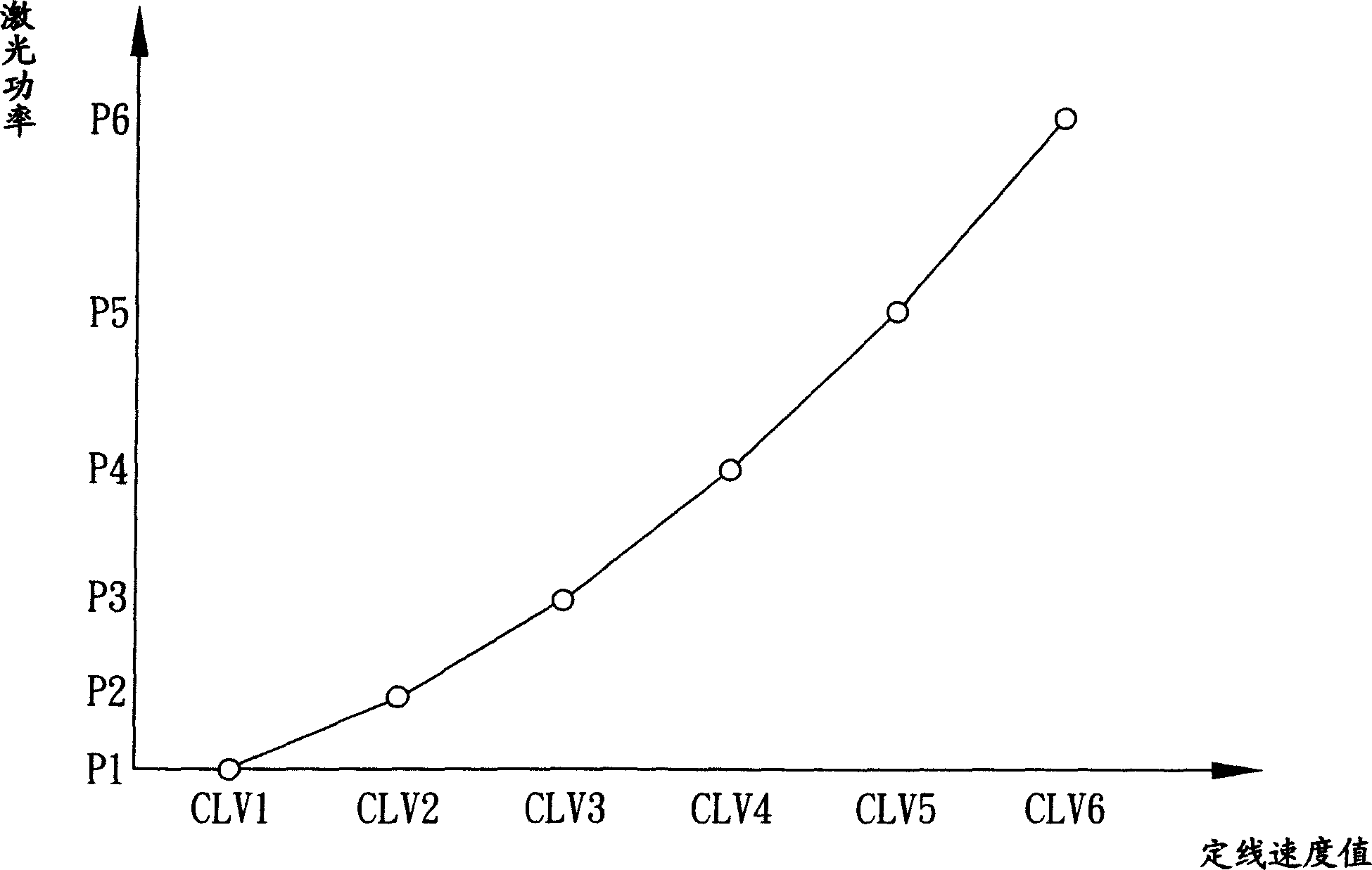

[0023] Please refer to image 3 , image 3 It is a schematic diagram of the relationship between the linear velocity value and the laser power in the preferred embodiment of the present invention. exist image 3 Among them, since the track width of the DVD disc is narrower than that of the VCD disc, in the CAV mode, the laser power of the optical read-write head when the data is written into the inner circle of the DVD disc and when the data is written into the outer circle of the DVD disc is different from the In addition to the direct ratio, the CLV value also showed the relationship of a quadratic curve distribution. Therefore, in order to reflect the factor that the track width of the DVD disc is narrower than that of the VCD track, the present invention considers changing the original linear relationship between the alignment velocity value and the laser power to a quadratic curve.

[0024] In the preferred embodiment of the present invention, in order to take the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com