Low-heat-value material gasification calcination device

A calcining device and low calorific value technology, applied in the field of low calorific value material gasification calcination device, can solve the problems of poor cement quality, uneven distribution of coal gangue, complicated process links, etc., to ensure environmental protection and operation safety, and uniform calcination temperature distribution , The effect of uniform distribution of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

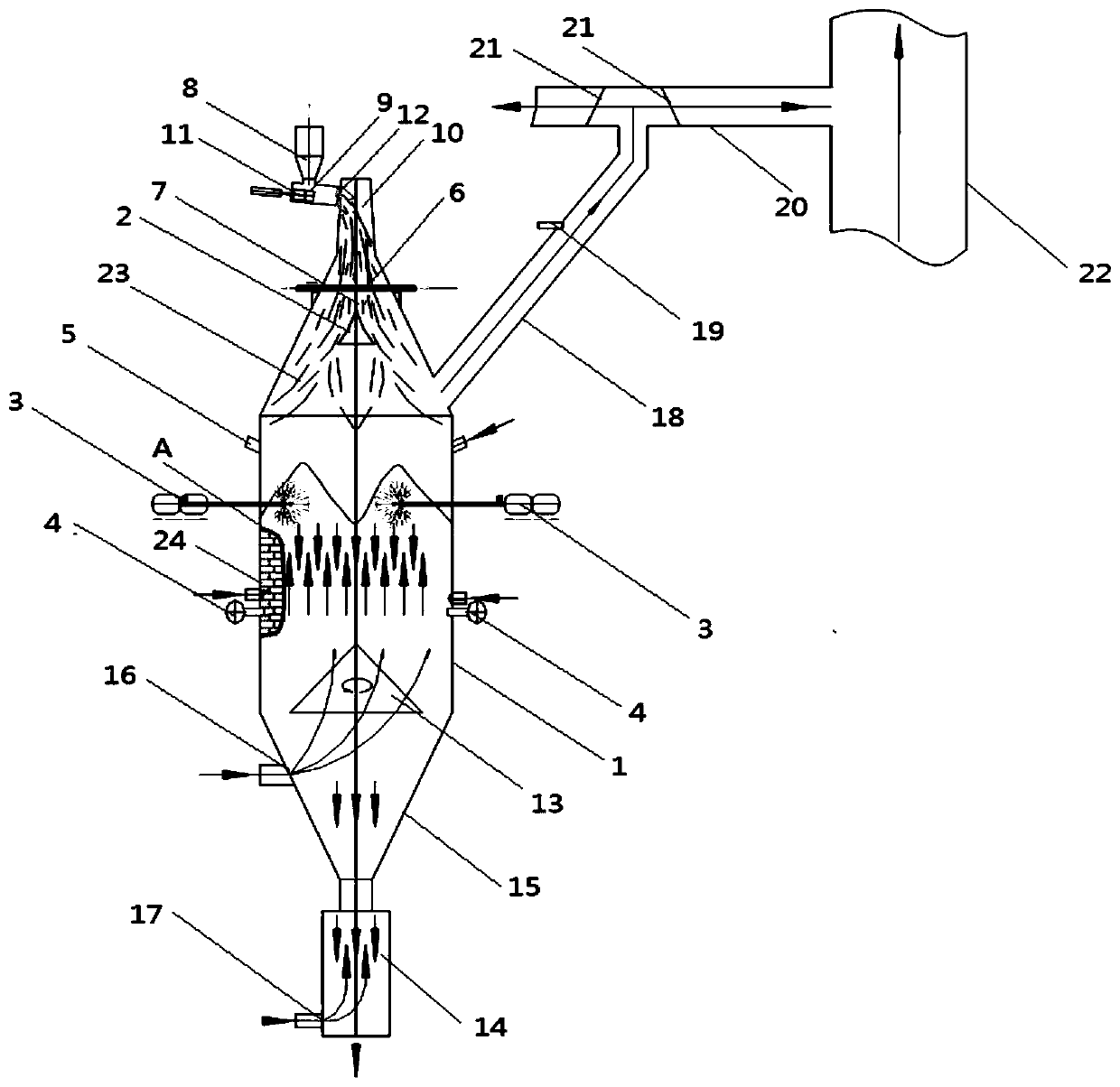

[0038] In order to understand the content of the present invention more clearly, it will be described in detail in conjunction with the accompanying drawings and specific embodiments.

[0039] Such as figure 1 as shown, figure 1 It is a schematic diagram of a specific embodiment of a low calorific value material gasification and calcination device provided by the present invention, wherein, part A is a partial cross-sectional view.

[0040] The invention provides a low calorific value material gasification and calcination device, which combines figure 1 As shown, the furnace body 1 is included, and the furnace body 1 is sequentially provided with a bulk material part and a material blowing and flattening part from top to bottom. The bulk material part includes a conical bulk material device 2 and a conical bulk material device. 2. Set upright, the material blowing and flattening part includes one or more material blowing parts 3, the material blowing parts 3 are arranged alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com