Multi-beam photoelectric sensor

A photoelectric sensor, multi-optical axis technology, applied in circuits, electrical switches, electrical components, etc., can solve the problem that the number of inventory management parts cannot be reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

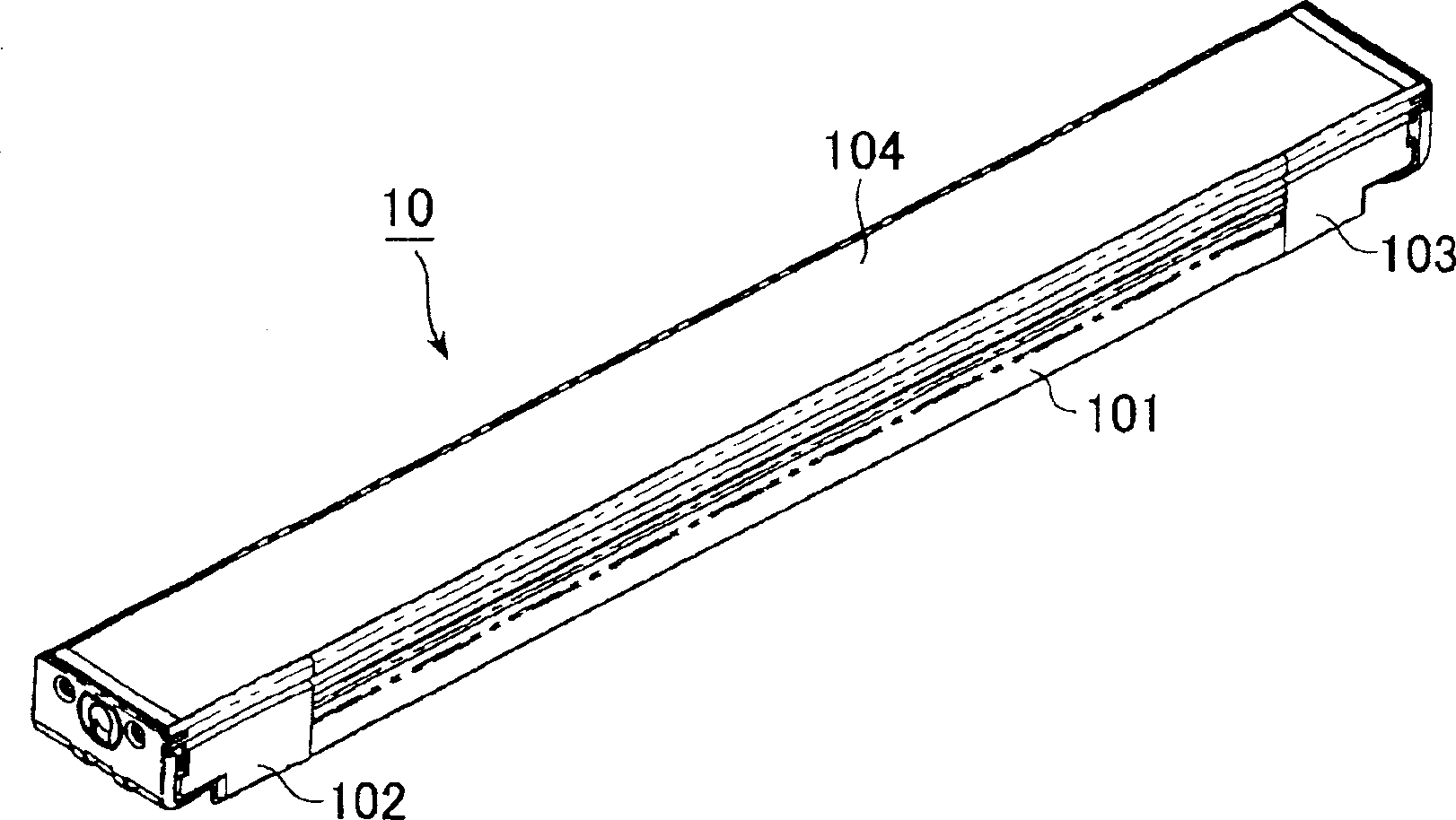

[0057] Hereinafter, a preferred embodiment of the present invention will be described in detail with reference to the drawings. The perspective view of the appearance of the light-projecting (or light-receiving) cylinder involved in the present invention is as follows: figure 1 shown. As shown in the same figure, the multi-optical axis photoelectric sensor according to the present invention has beams 10 for light projection and light reception which are arranged oppositely when in use.

[0058] The container of this cylinder 10 has a columnar container body 101, an end cap 102 blocking one end opening of the columnar container body, an end cap 103 blocking the other end opening, and a front panel 104 blocking the front side. As will be described in detail later, the columnar container body 101 and the end caps 102 and 103 are made of metal and have a substantially U-shaped cross section. The front panel 104 adopts a plastic plate transparent to the light used. The sensor as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com