Steepless gear in three conditions for vehicles

A continuously variable transmission, continuously variable transmission technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of not continuously variable transmission, low efficiency of hydraulic torque converter, and no self-production. , to reduce costs, improve transmission efficiency, and achieve the effect of smooth changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

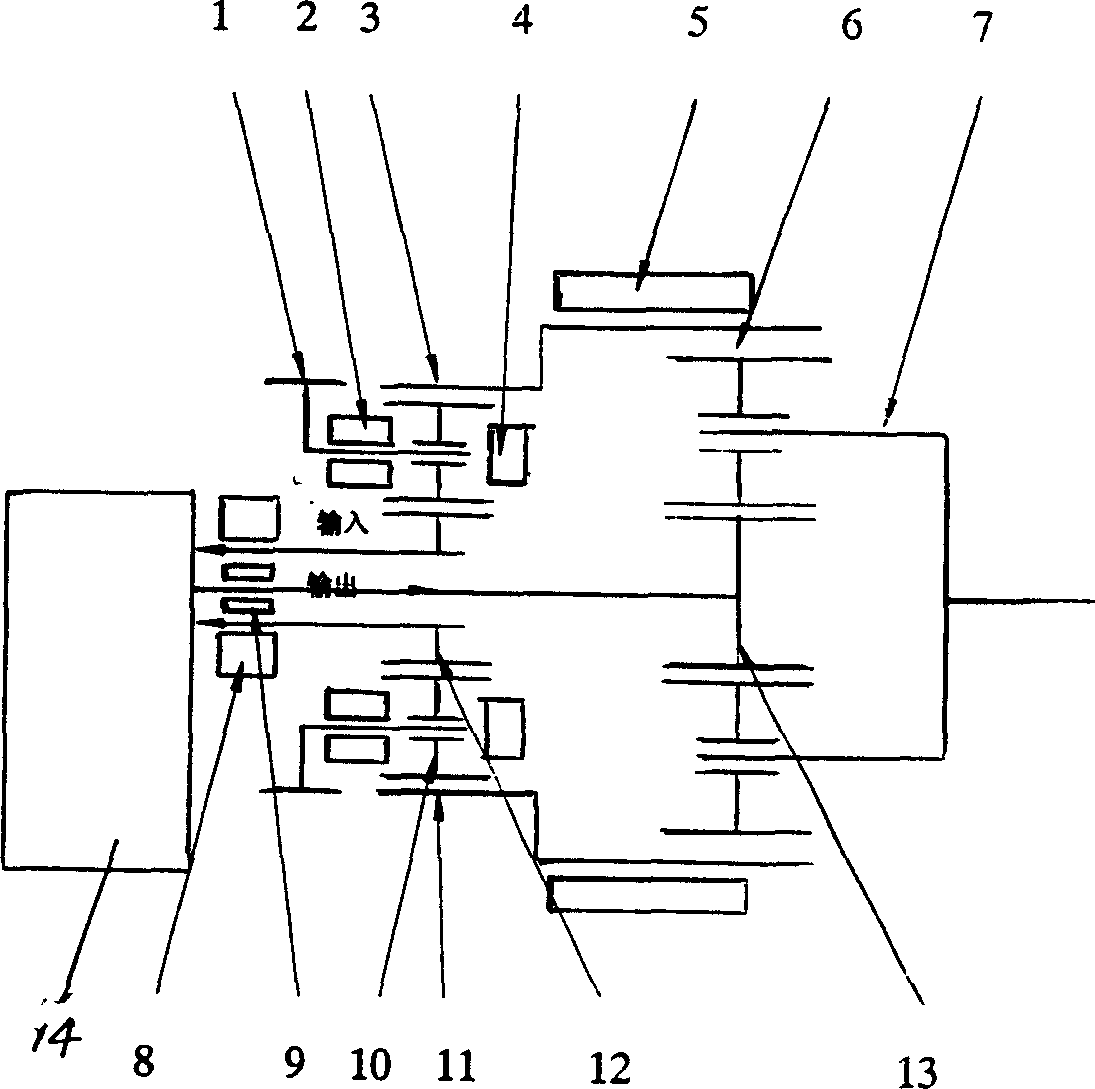

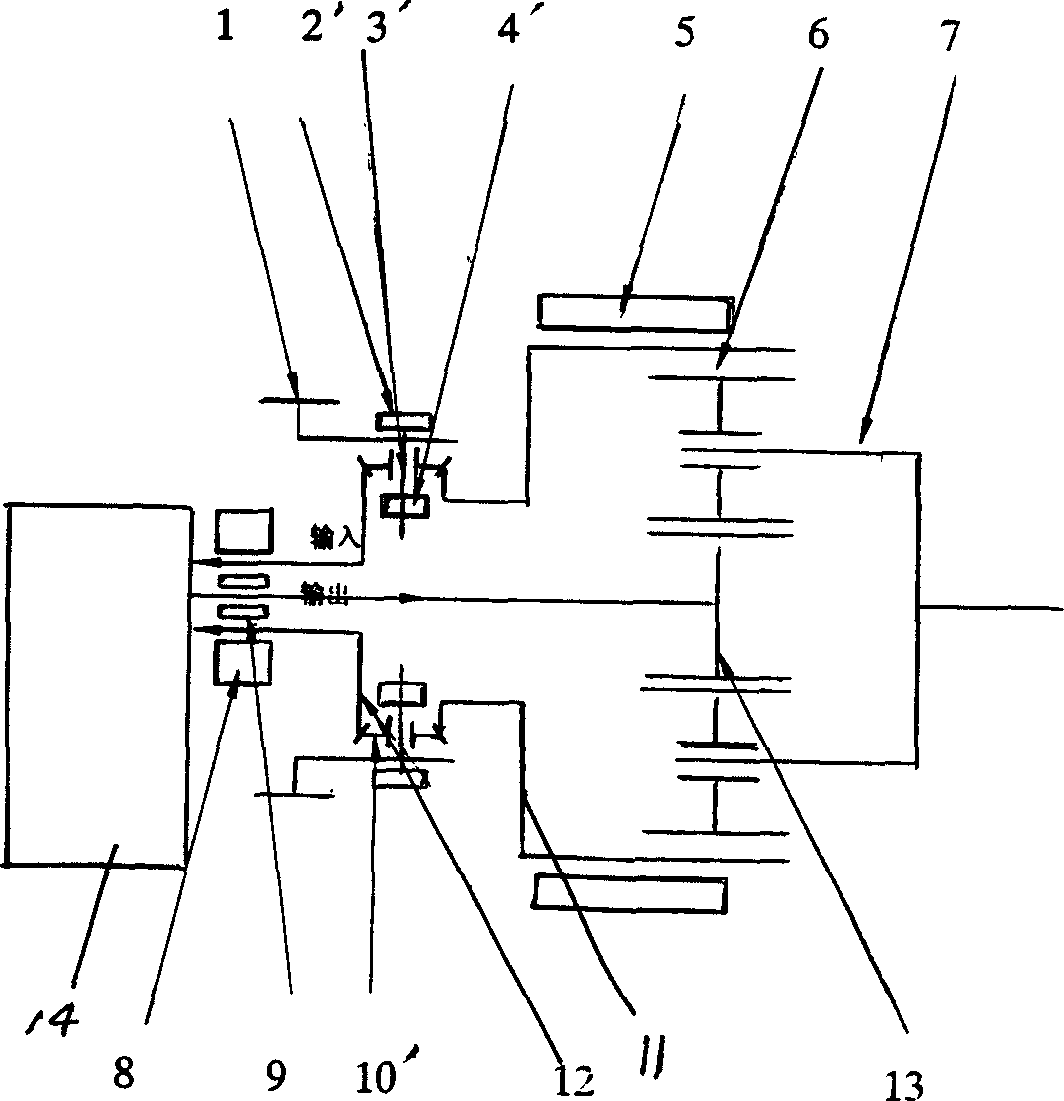

[0015] Refer to attached figure 1 , 2 , the structural characteristics of the three-state continuously variable transmission for vehicles are (as attached figure 1 ): the front planetary row (3) and the rear planetary row (6) are coaxial, the outer ring gears (11) of the front and rear planetary rows are integrated or fixedly connected, the front planetary carrier connecting gear (1) receives the power of the engine, and the front sun The wheel (12) is connected to the active part of the existing continuously variable transmission through the hollow shaft, and an asteroid row can be connected in series between the two. By controlling the asteroid row, neutral gear and reverse gear can be realized. The driven part of the existing continuously variable transmission The rear sun gear (13) is connected through the shaft, and the rear planetary carrier (7) outputs power; the clutch (8) is installed on the shaft connected with the rear sun gear (13), and is used to control the dy...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap