Target type sensor of liquid speed

A fluid velocity and sensor technology, applied in fluid velocity measurement, velocity/acceleration/impact measurement, instruments, etc., to achieve economical, reliable and responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

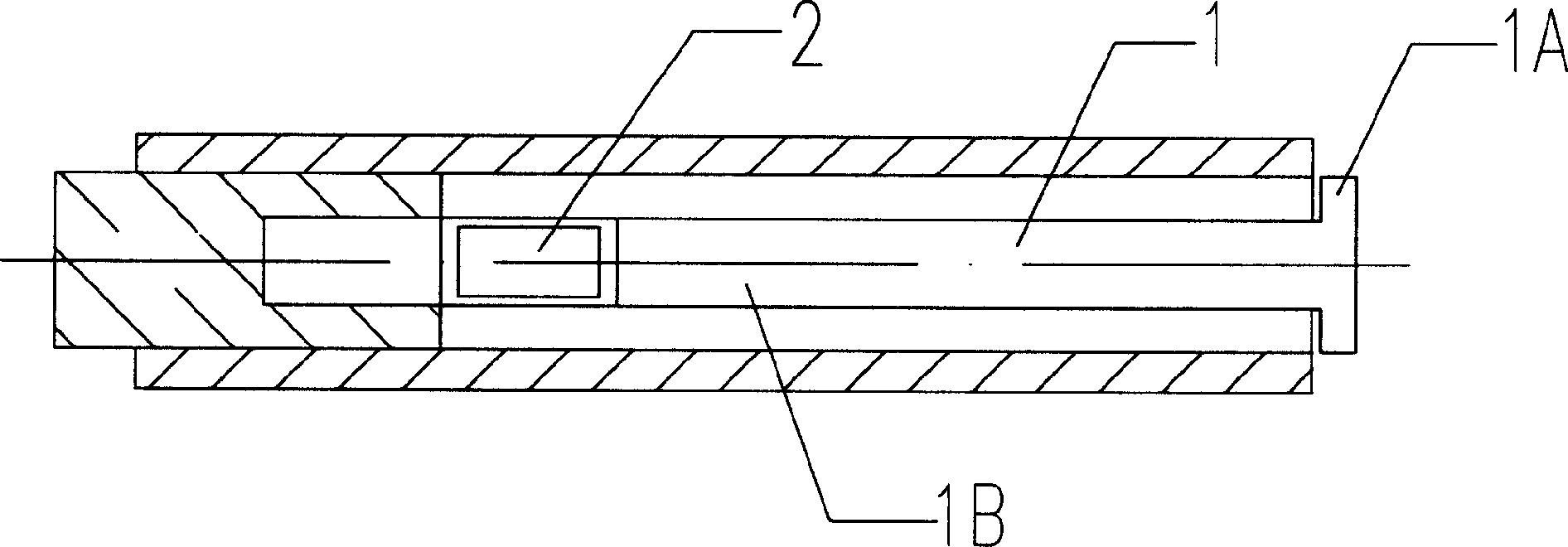

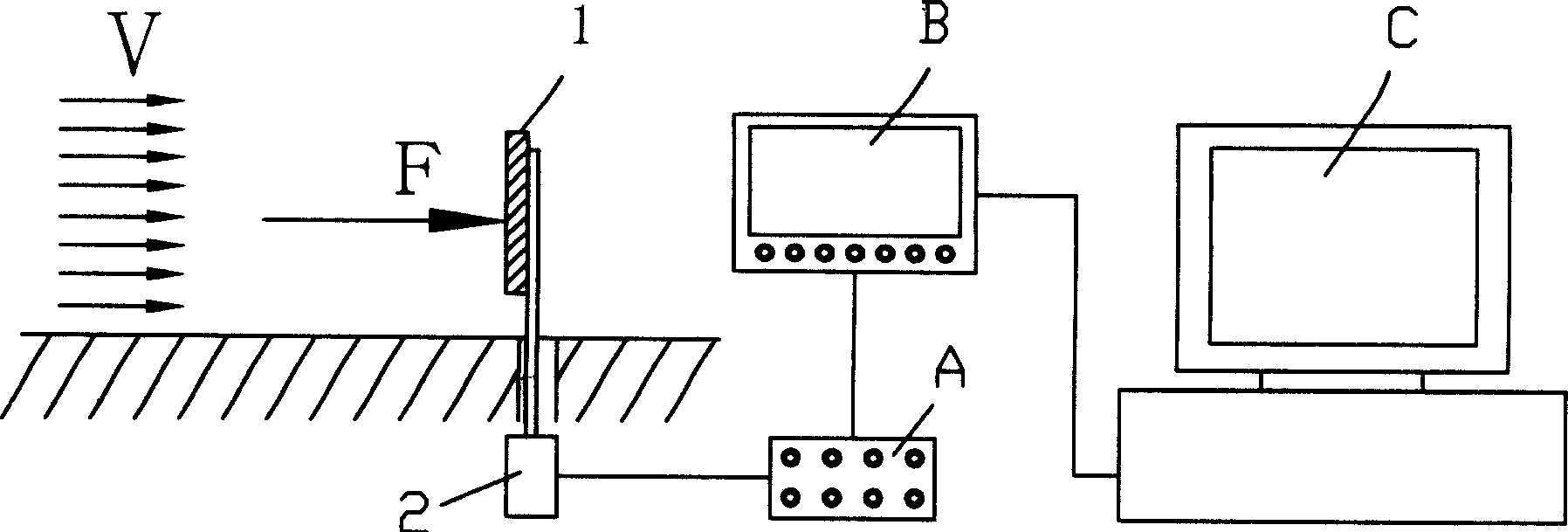

[0014] The structure diagram of the present invention is as figure 1 As shown, it includes a target 1, two strain gauges 2, and a target rod holder 5, wherein the target 1 includes a target surface 1A and a target rod 1B, and the target rod 1B is fixed on the target rod holder 5, and the two strain gauges 2 Stick on the upper and lower sides of the target rod 1B respectively.

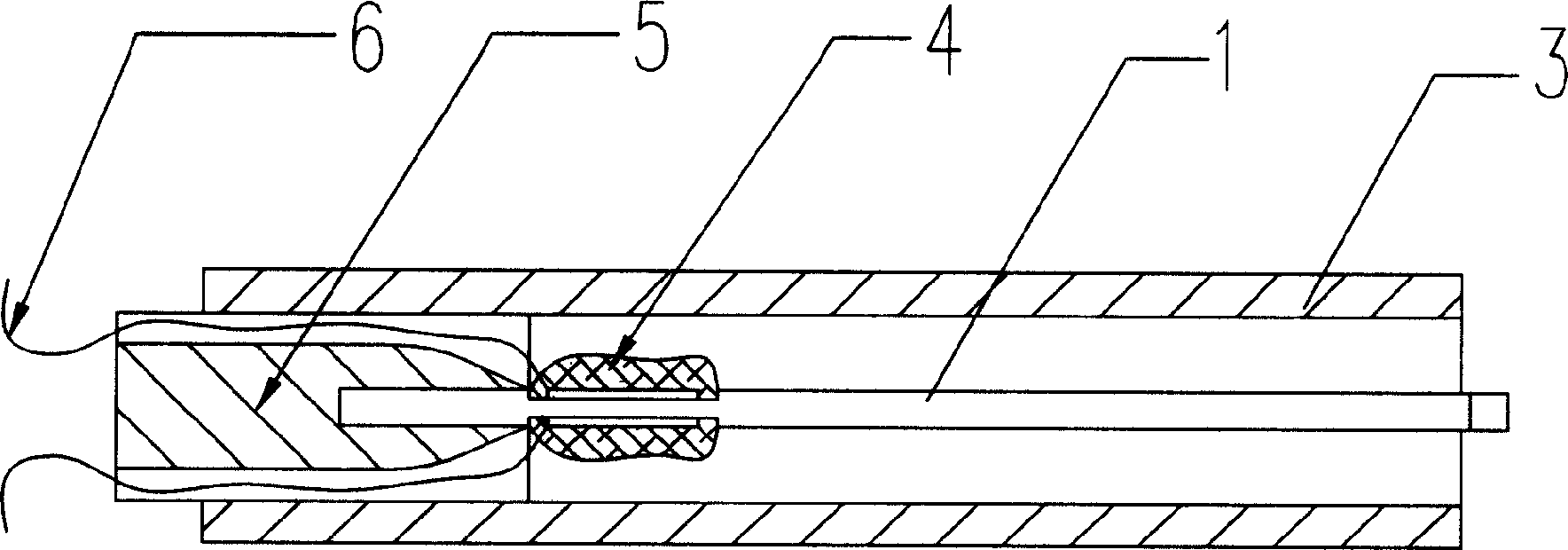

[0015] In order to make the speed measured by the sensor be the speed at the center of the target surface, the outer side of the above-mentioned target rod 1B is covered with a sleeve 3, the target surface 1A is exposed at the end of the sleeve 3, and the target surface 1A is exposed at the end of the sleeve. The area of the end of the barrel 3 matches the measurement range and the rigidity of the target rod 1B. Since the outer surface of the target 1 is covered with the sleeve 3, it can be ensured that the impact force of the measured fluid only acts on the area of the target surface exposed from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com