Water filter

A water filter and filter cup technology, applied in the direction of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems of water filter clogging, large sand content, clogging, etc., achieve complete sewage discharge, save production costs, Reduce the effect of the reduction gear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further description will be given below in conjunction with the accompanying drawings, but not limited thereto.

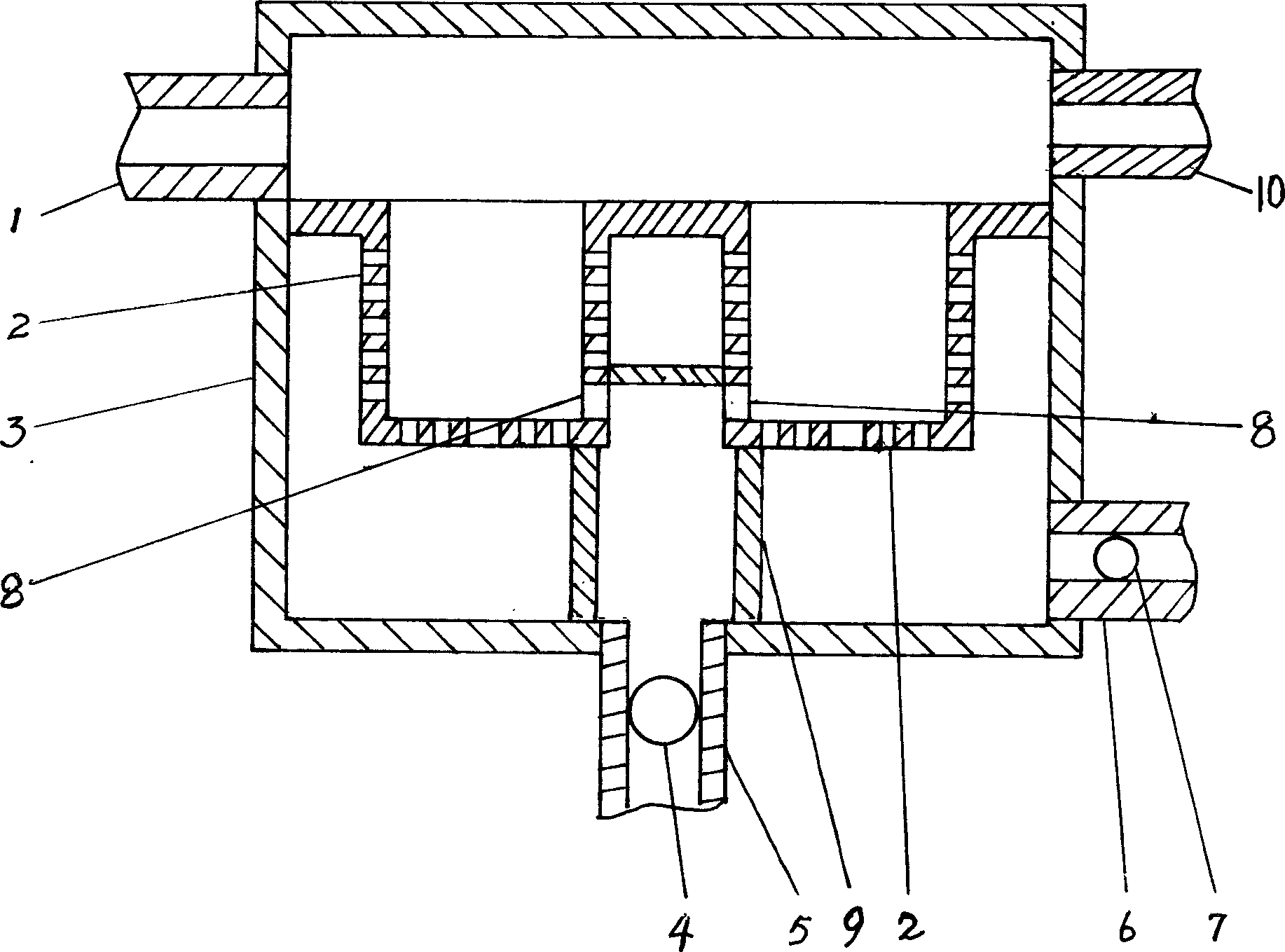

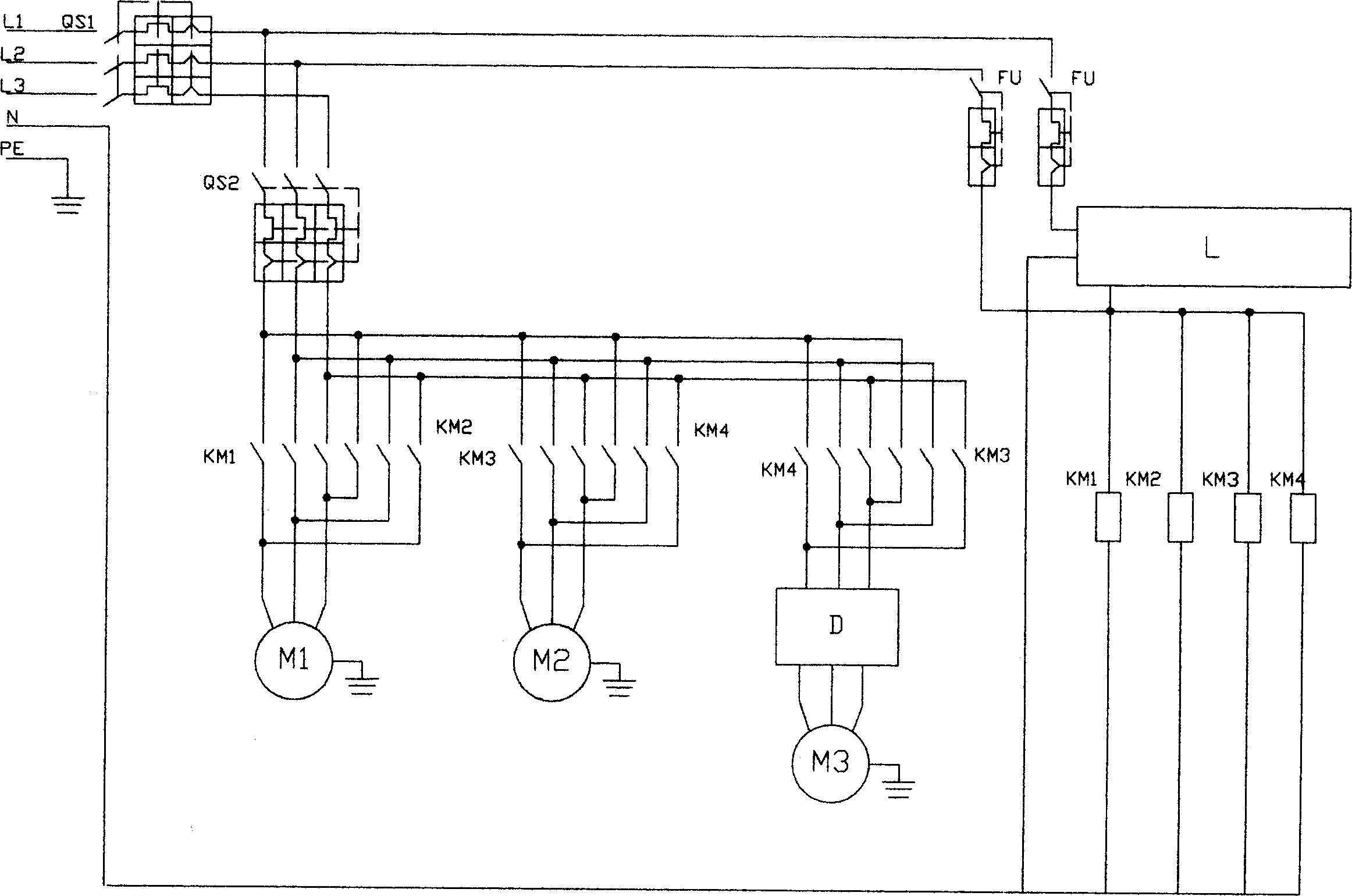

[0014] Such as figure 1 , 2 As shown, the present invention comprises a water inlet pipe 1, a casing 3, a filter cup 2 placed in the casing 3, a sewage outlet 8 opened on the filter cup 2, a sewage collection box 9 connected with the sewage outlet 8, connected to the The waste discharge pipe 5, the floating object outlet 10, and the water outlet pipe 6 of the sewage collection tank 9 are provided with a water discharge valve 7 on the water discharge pipe 6, and a sewage discharge valve 4 is provided on the sewage discharge pipe 5, and the water discharge valve 7 and the sewage discharge valve 4 are linked in reverse state , the reverse state linkage mode adopts the control motor M3 of the water outlet valve 7 and the control motor M2 of the sewage valve 4 to be powered by the same power supply and the phase sequence is reversed; the connection relationship ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com