Constant pressure jet water purifier

A jet type, water purifier technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of long backwashing time of filtering sand layer and affecting the water production efficiency of equipment , filter sand layer load and other problems, to achieve the effect of small footprint, ingenious structure and good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

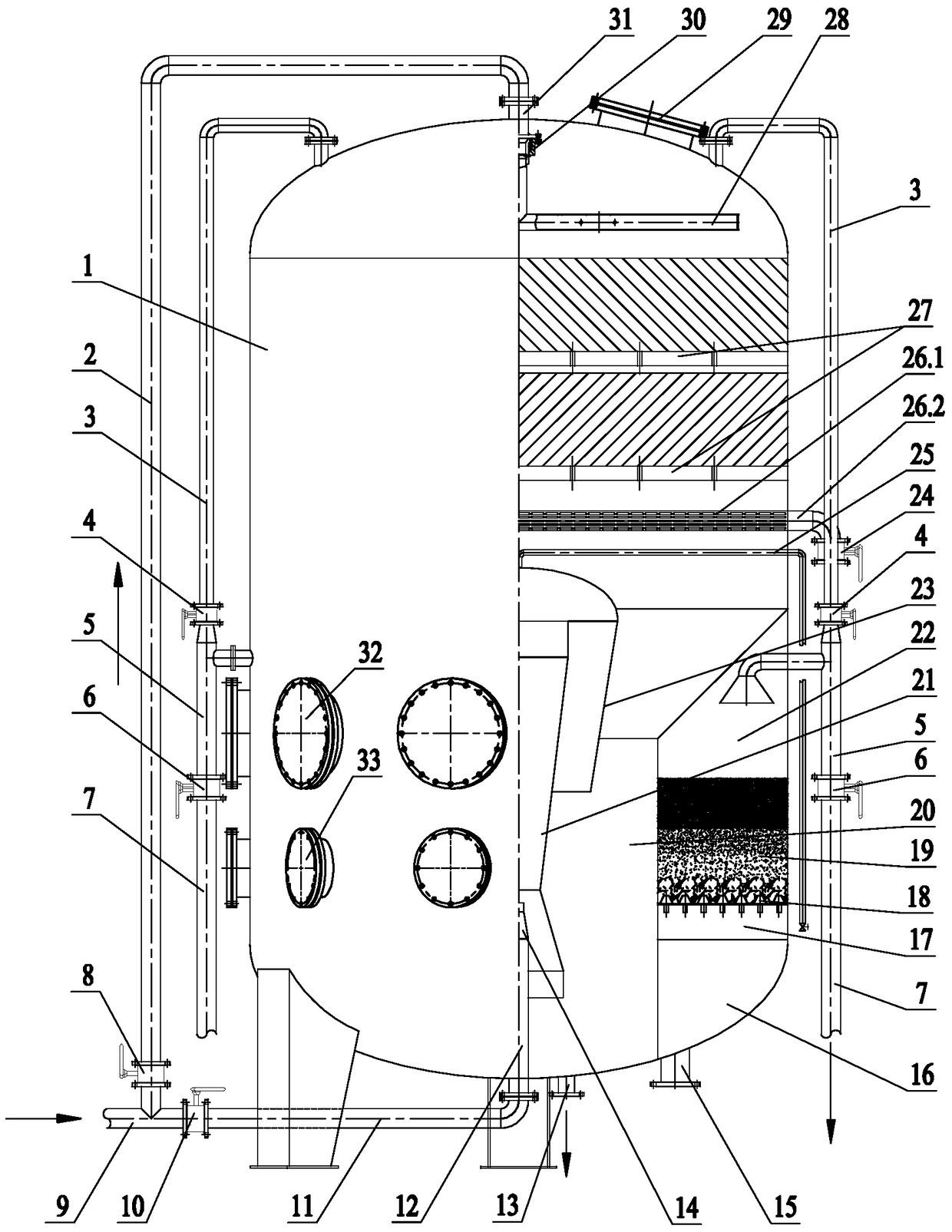

[0020] As shown in the figure: the constant pressure jet water purifier in the embodiment is mainly composed of the housing 1, the inclined plate recoil pipe 2, the three water distribution pipes 3, the water distribution switch valve 4, the through pipe 5, and the recoil sewage switch valve 6. , Recoil sewage pipe 7, inclined plate backwash switch valve 8, raw water pipeline 9, water inlet switch valve 10, water inlet pipe 11, nozzle pipe 12, sewage pipe 13, nozzle 14, water outlet pipe 15, clean water zone 16, filter Plate 17, drain cap 18, filter material 19, settling chamber 20, mixing chamber 21, filter chamber 22, reaction chamber 23, intermediate drain switch valve 24, vent pipe 25, intermediate sewage collection pipe assembly 26.1, intermediate sewage pipe 26.2 , Perforated inclined plate 27, T-shaped spray pipe 28, maintenance manhole 29, rotary joint 30,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com