Indoor unit for air conditioner

A technology for indoor units and air conditioners, which is applied in the field of indoor units, can solve problems such as damaging the indoor appearance, and achieve the effect of improving the appearance and reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0065] [Overall structure of the air conditioner]

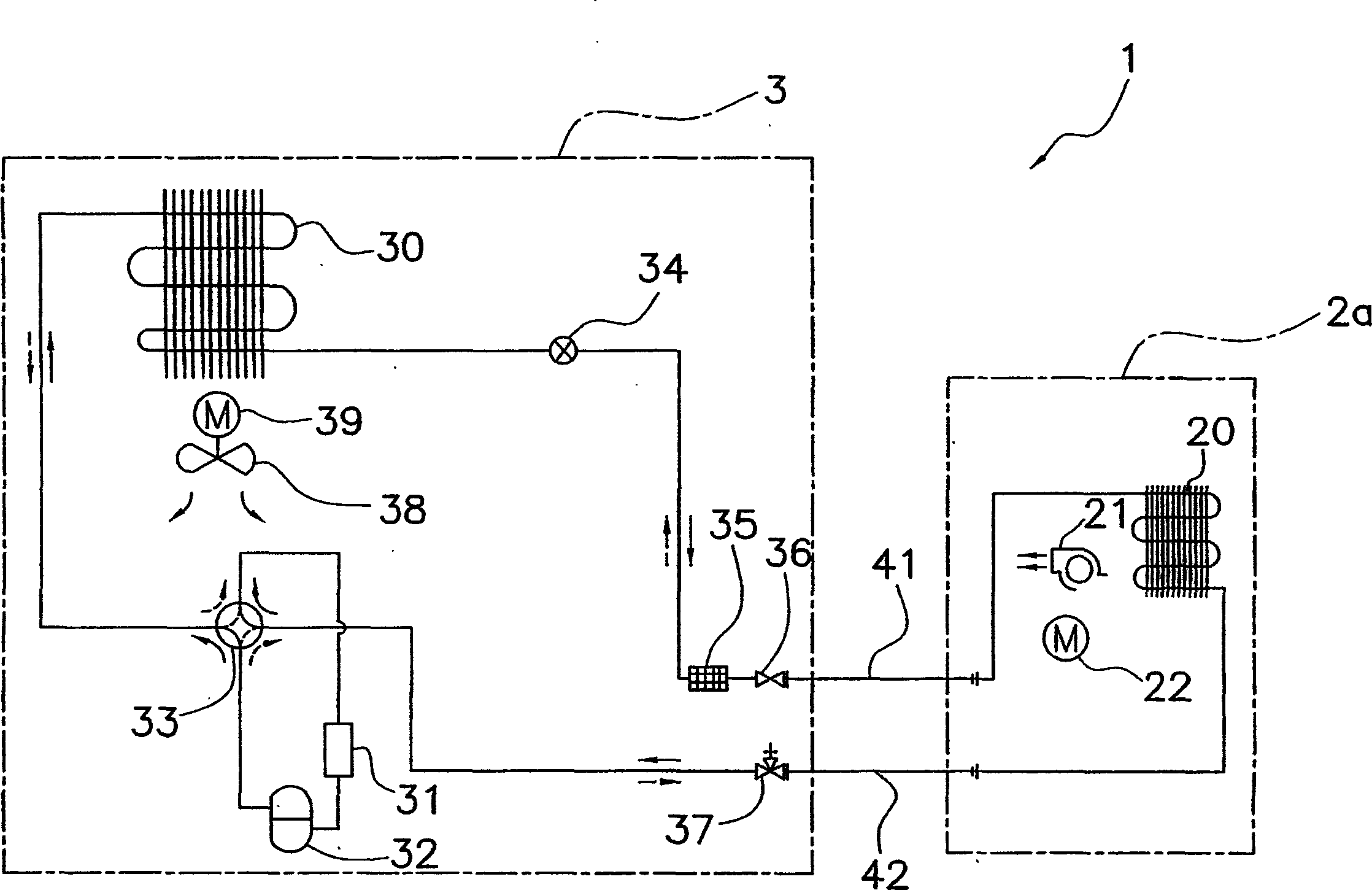

[0066] figure 1 The configuration of the air conditioner 1 and the basic configuration of the refrigerant circuit according to the first embodiment are shown.

[0067] This air conditioner 1 includes an indoor unit 2a mounted on an indoor wall or the like, and an outdoor unit 3 installed outdoors.

[0068] The refrigerant circuit of the air conditioner 1 is mainly composed of the following components: an indoor heat exchanger 20 , an accumulator 31 , a compressor 32 , a four-way reversing valve 33 , an outdoor heat exchanger 30 and an electric expansion valve 34 .

[0069] The indoor heat exchanger 20 provided in the indoor unit 2a performs heat exchange with the air in contact with it. In addition, the indoor unit 2a is provided with an indoor fan 21 for sucking in indoor air and discharging the air heat-exchanged by the indoor heat exchanger 20 into the room. The indoor fan motor 22 provided in the indoor unit 2a drives...

no. 2 Embodiment approach

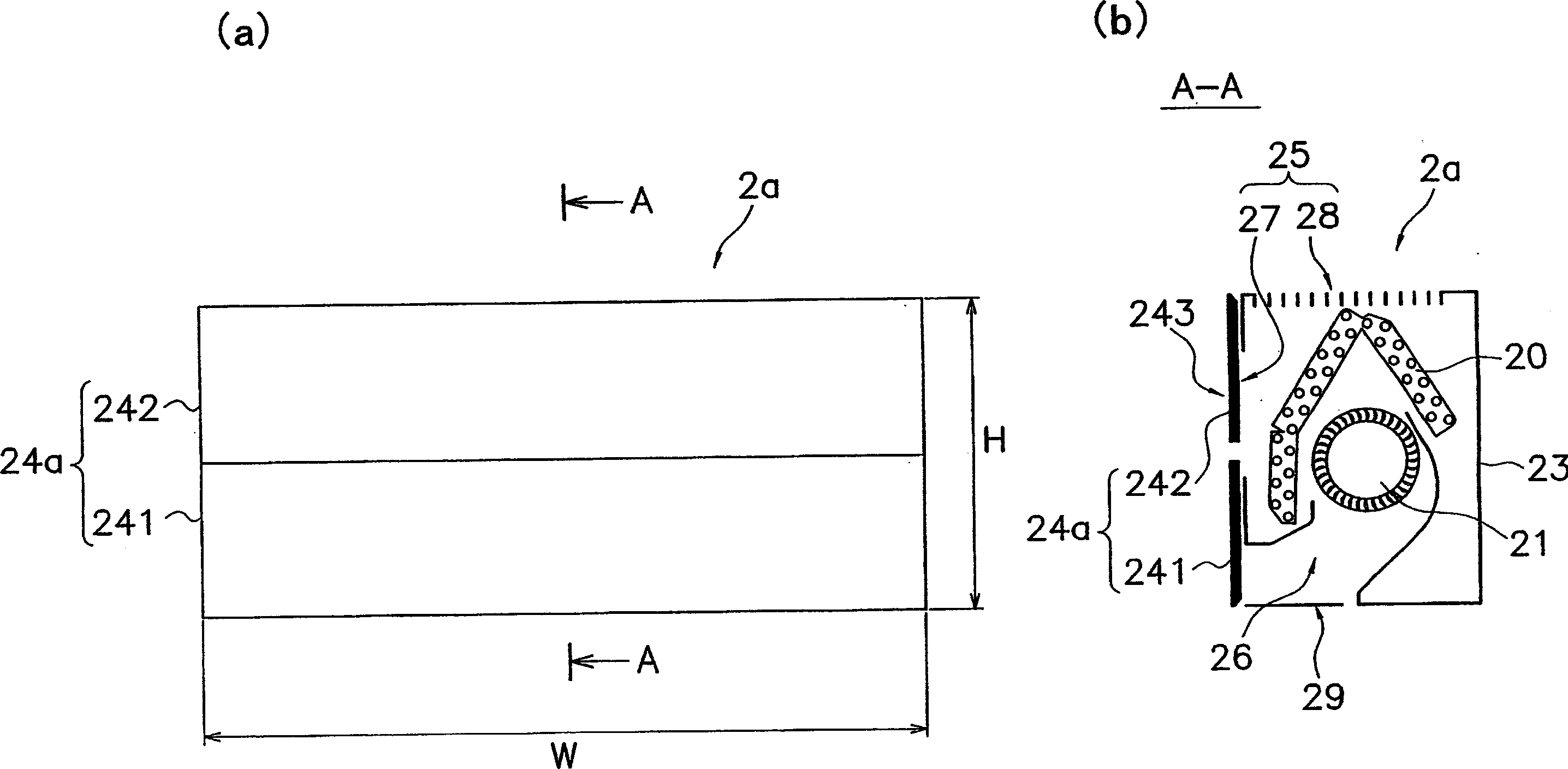

[0103] Figure 4 (a) and Figure 4 (b) shows the indoor unit 2b of the air conditioner 1 of the second embodiment of the present invention. Figure 4 (a) is a front view when the indoor unit 2b is stopped. Figure 4 (b) is a side sectional view when the indoor unit 2b is stopped.

[0104] This indoor unit 2b has a front panel 24b that covers substantially the entire front of the casing main body 23 . The front panel 24b is a seamless flat plate-like member when viewed from the front, and is formed as a flat surface 244 parallel to the vertical direction with the air outlet 26 and the first suction inlet 27 closed. In addition, when viewed from the front, the front panel 24b has a long rectangular shape in the horizontal direction, and when viewed from the front, it has a width W equal to that of the casing main body 23 including the air outlet 26 and the first suction port 27. About the same width. The front panel 24b is used to open and close the blowout port 26 and the ...

no. 3 Embodiment approach

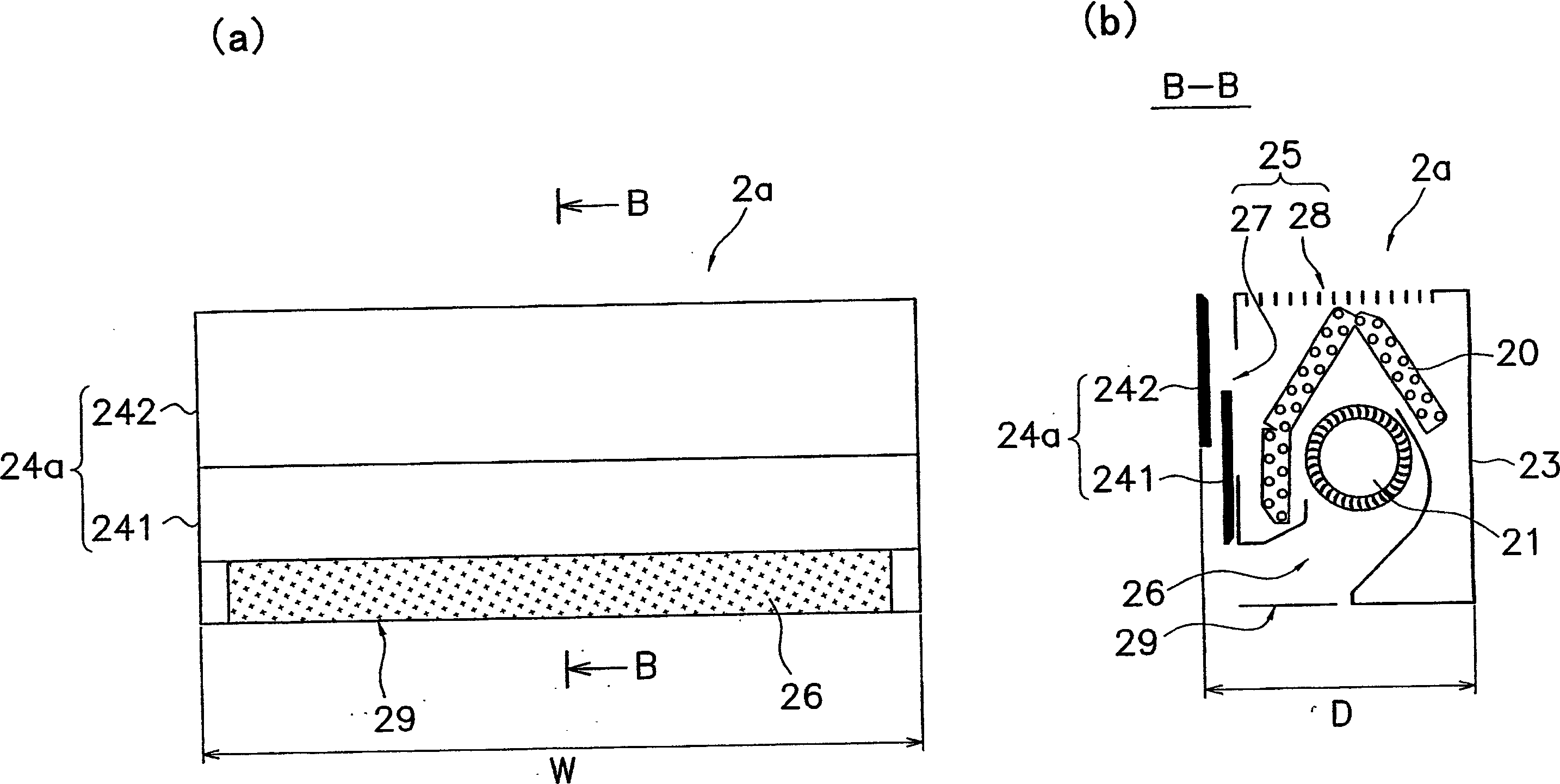

[0111] Figure 6 (a) and Figure 6 (b) shows the indoor unit 2c of the air conditioner 1 which concerns on 3rd Embodiment of this invention. Figure 6 (a) is a side sectional view when the indoor unit 2c is stopped. Figure 6 (b) is a side sectional view when the indoor unit 2c is in operation.

[0112] This indoor unit 2c has a front panel 24c covering the entire front of the indoor unit 2c. The front panel 24c is used to open and close the air outlet 26 and the first air inlet 27 . The front panel 24c covers the air outlet 26 and the first air inlet 27 when viewed from the front in a state in which the air outlet 26 and the first air inlet 27 are closed. This front panel 24c is a seamless plate-shaped member when viewed from the front, and has a first flat surface portion 245 and a second flat surface portion 246 . Both the first planar portion 245 and the second planar portion 246 have a flat plate-like shape. The first plane portion 245 is parallel to the vertical di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com