Portable tool machine fixation frame

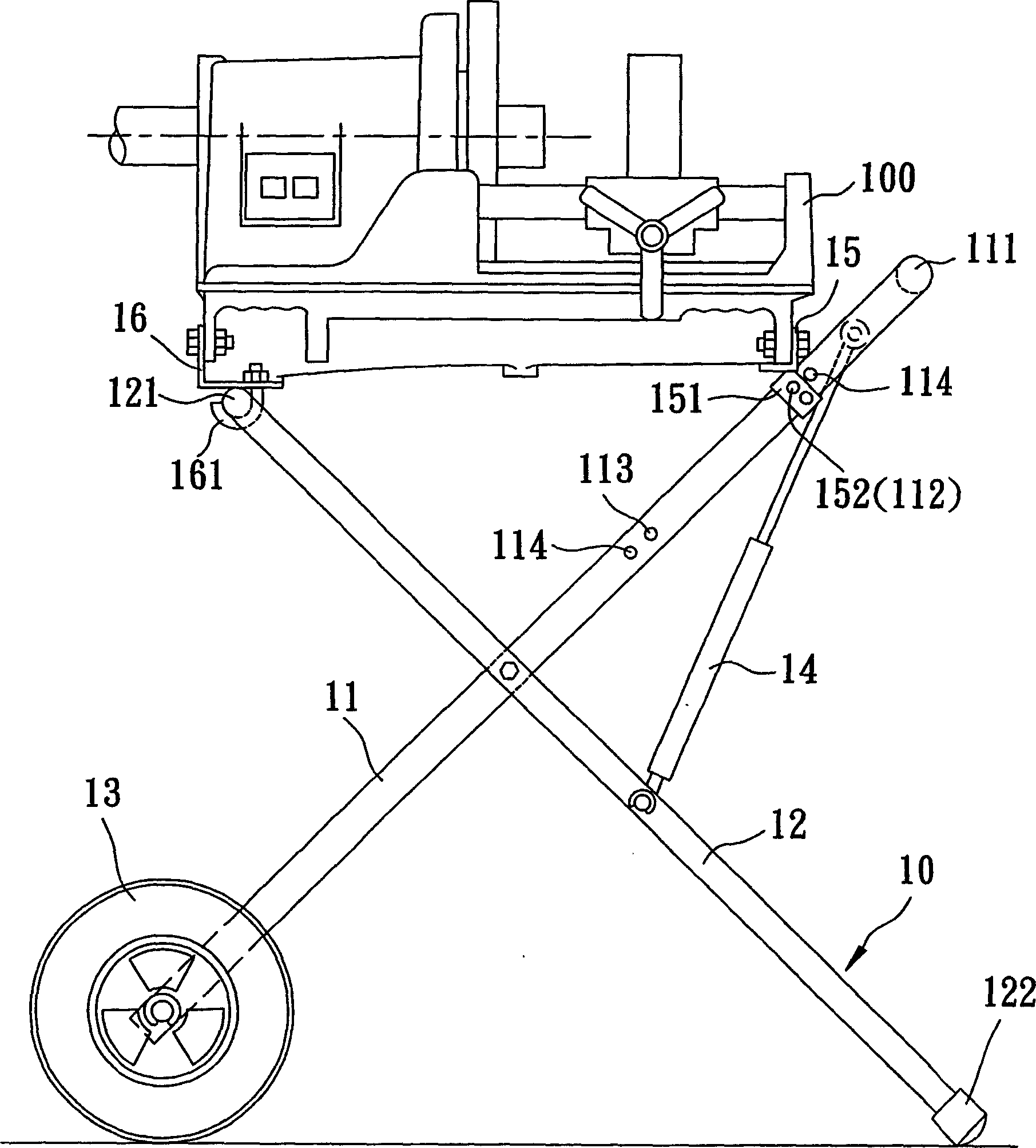

A technology of machine tools and fixing frames, which is applied in the field of movable machine tool fixing frames, can solve the problems of easy accidents, inability to install different sizes or other types of machine tools, and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings.

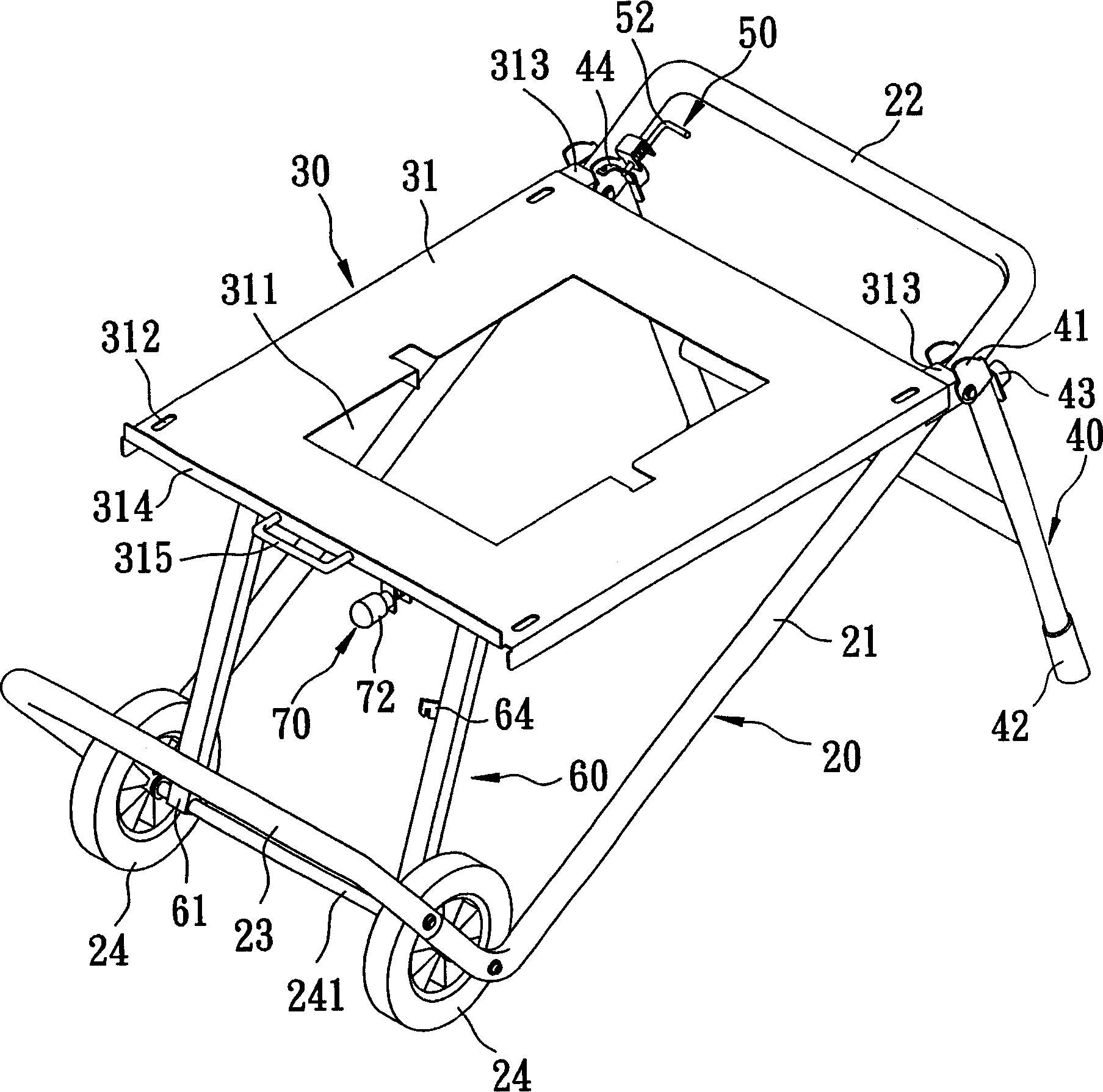

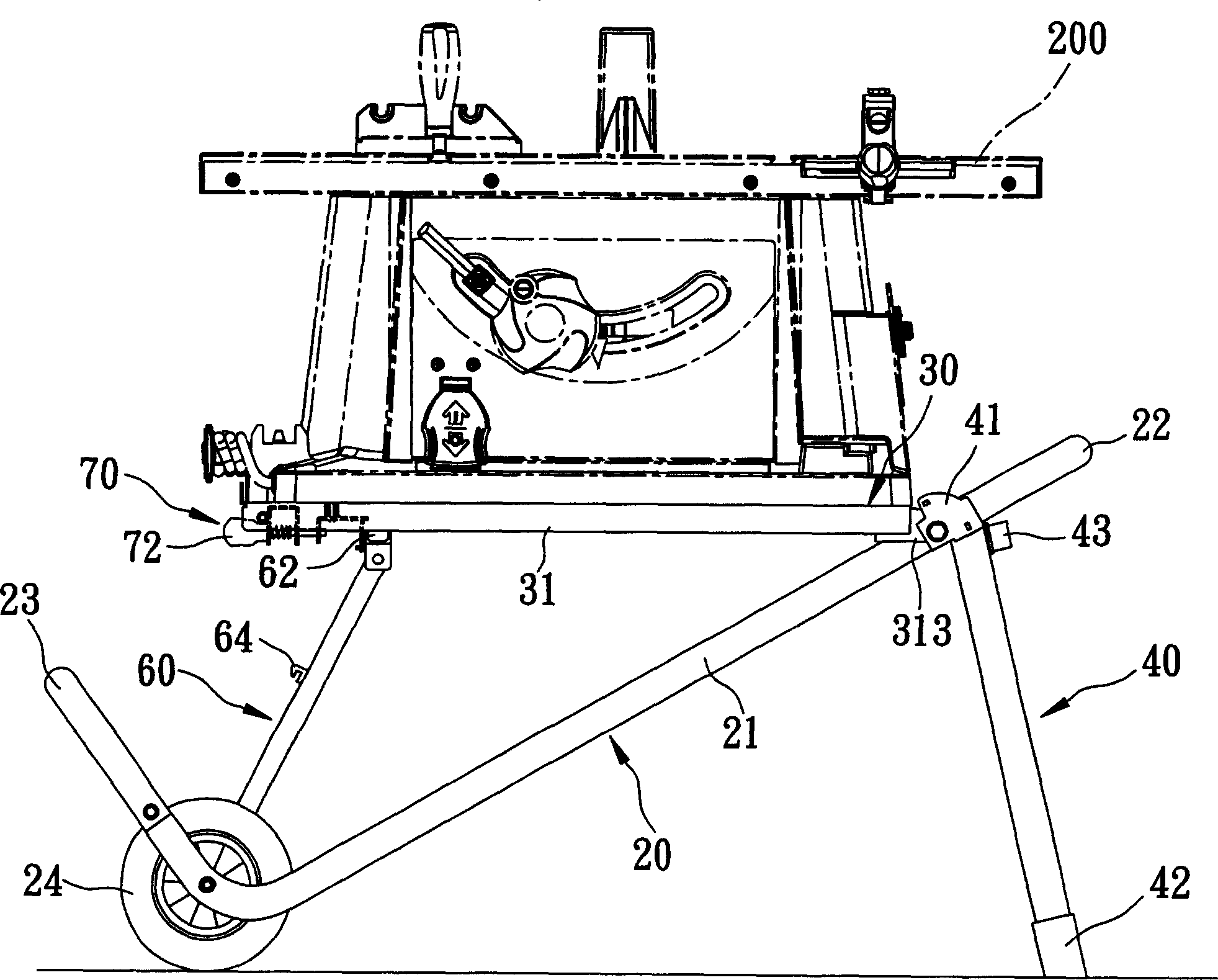

[0036] see figure 2 , image 3 As shown, in a preferred embodiment, the movable machine tool holder of the present invention includes a wheel carrier 20, a platform unit 30, a front foot frame 40, a front locking unit 50, a rear foot frame 60 and a The rear locking unit 70, then, the shape and combination of the above components will be described in detail later.

[0037] The wheel carrier 20 is a slightly L-shaped frame, which has a main frame rod 21, a handle rod 22 connected to the upper end of the main frame rod 21, and a 90-degree bent extension from the lower end of the main frame rod 21. The upright blocking bar 23 and the wheels 24 at the lower end of the main frame bar 21 are arranged on two axles, and a wheel axle 241 is horizontally arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com