Cutting member of mud digging system

A technology of cutting parts and mud system, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. The effect of simple connection and disconnection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

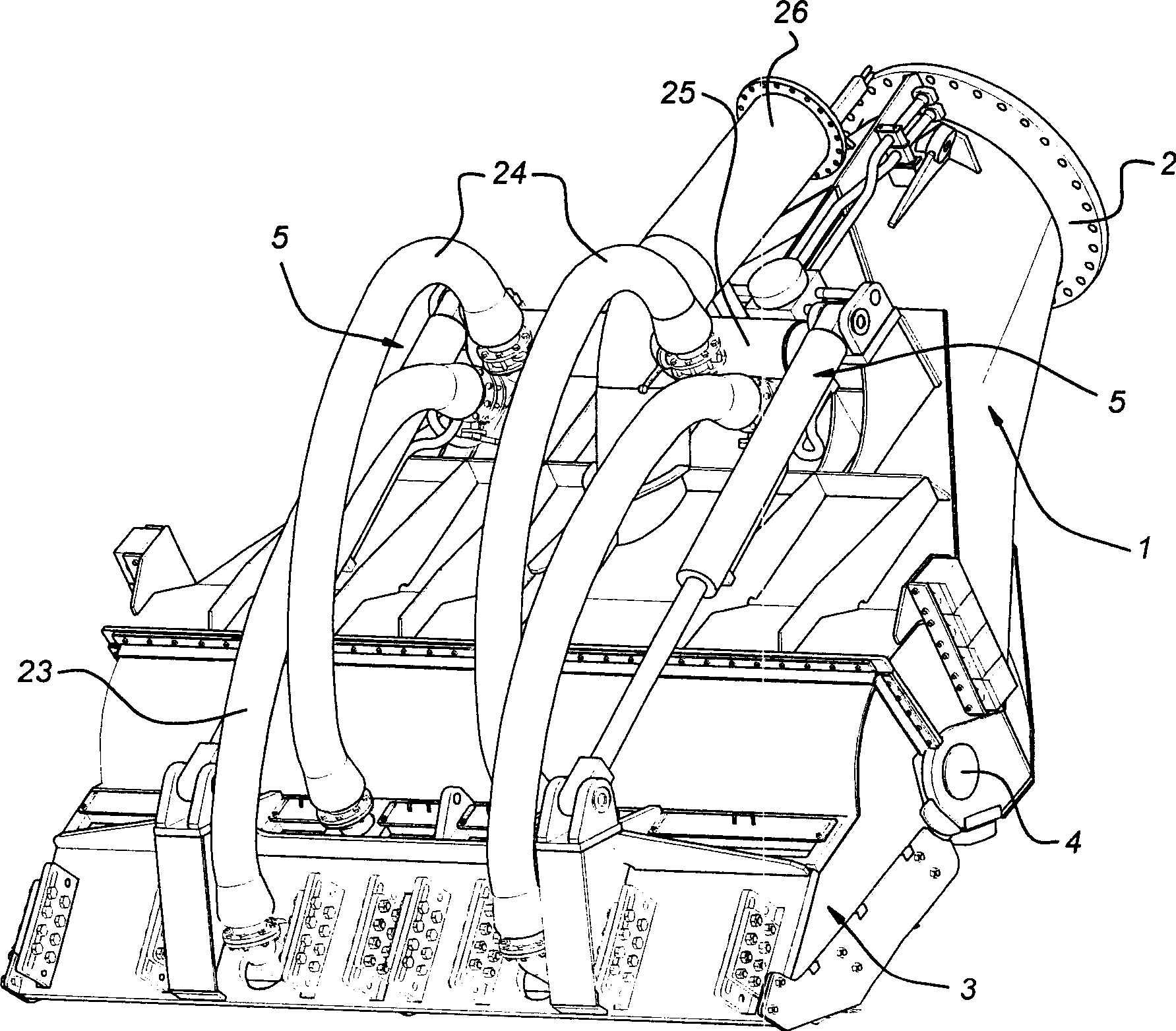

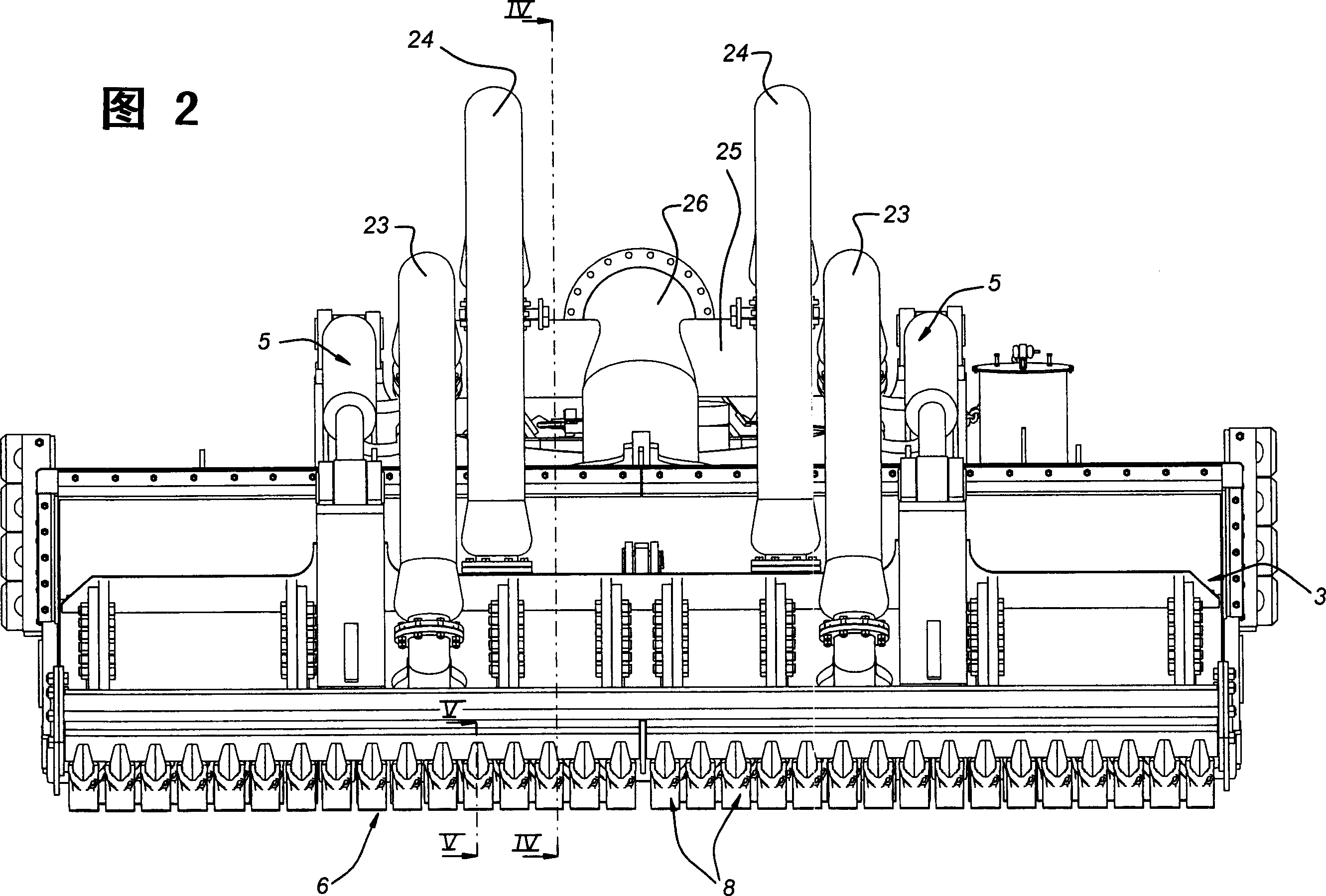

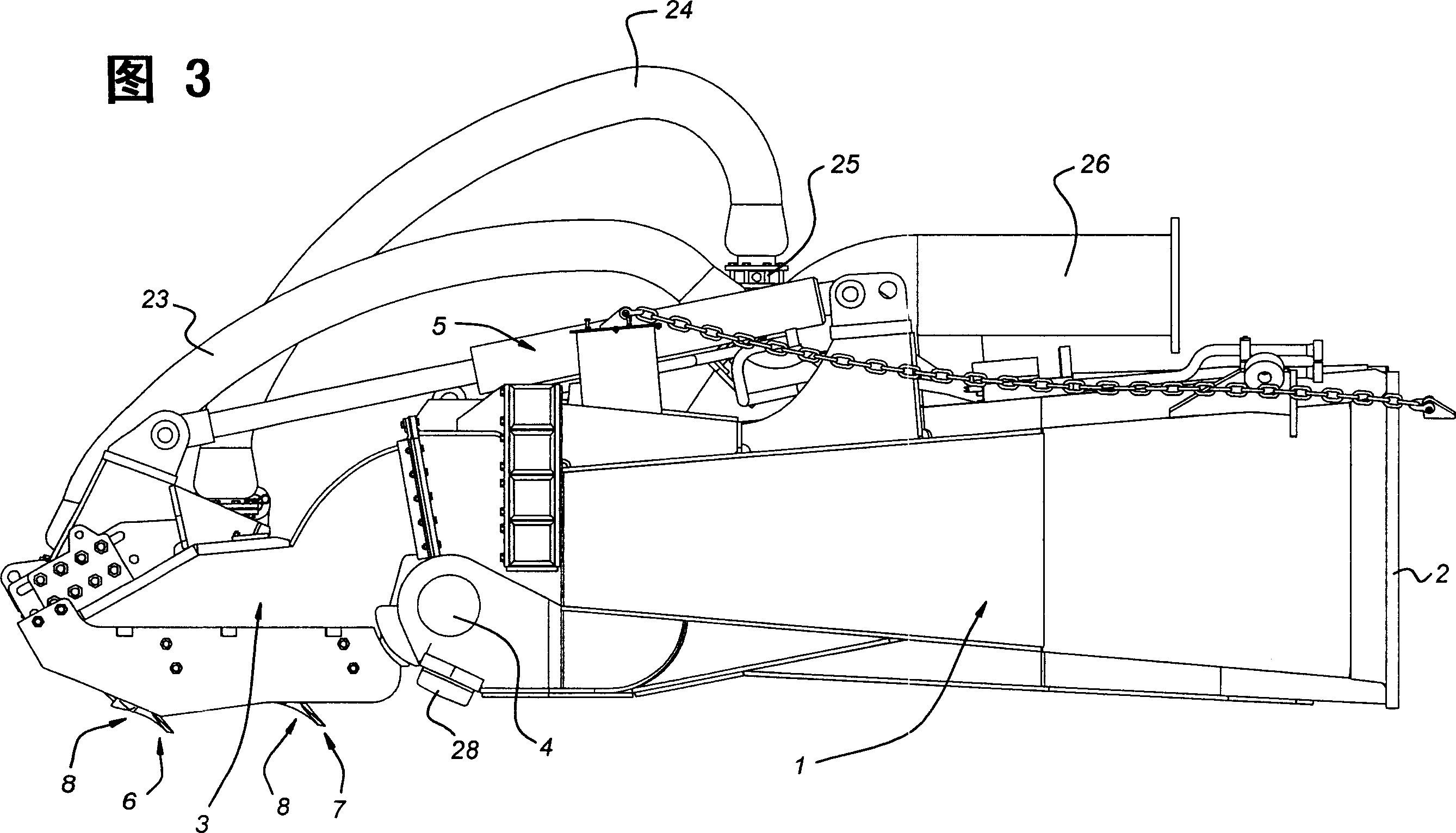

[0018] figure 1 The rake head shown in -3 includes a main body 1 with a mounting flange 2 at one end. Via the mounting flange 2, the drag head can be connected to a suction pipe and an excavation container (not shown in the figure). The other end of the body 1 carries a so-called visor 3 via a hinged connection 4 . The inclination direction of the shield plate 3 relative to the body 1 can be adjusted by a hydraulic piston / cylinder device 5 .

[0019] The visor 3 carries two rows 6, 7 of cutters 8 each with a nozzle 36 (other numbers of rows are also possible). These cutouts are enlarged and shown in Figure 5 middle. Each cutting element 8 comprises a cutting tooth 9 and a tooth holder 10 . The tooth holder 10 has a mounting part 11 which connects the tooth holder to a crossbar 12 on each row 6,7. Furthermore, each tooth 9 has a cavity 14 in which the prongs 13 of the mounting part 11 fit tightly. Axial displacement is prevented by pins (not shown) inserted into the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com