Non-dispersive infrared gas sensor and operation method thereof

A gas sensor and operation mode technology, applied in instruments, scientific instruments, analytical materials, etc., can solve problems such as poor resistance to harsh environmental influences, strong resistance to harsh environmental influences, and difficulty in mass production processes, and achieve small The ability to resist the impact of harsh environments, the production process is less difficult, and the after-sales maintenance is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

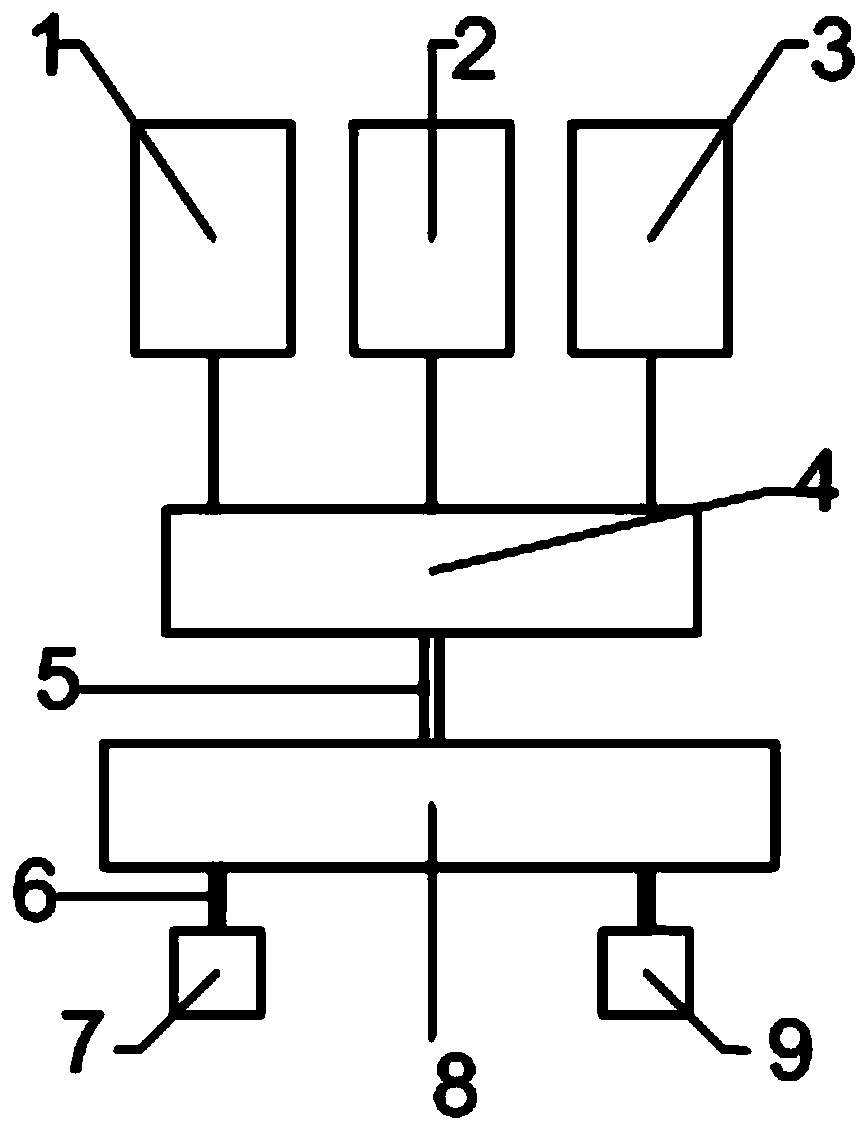

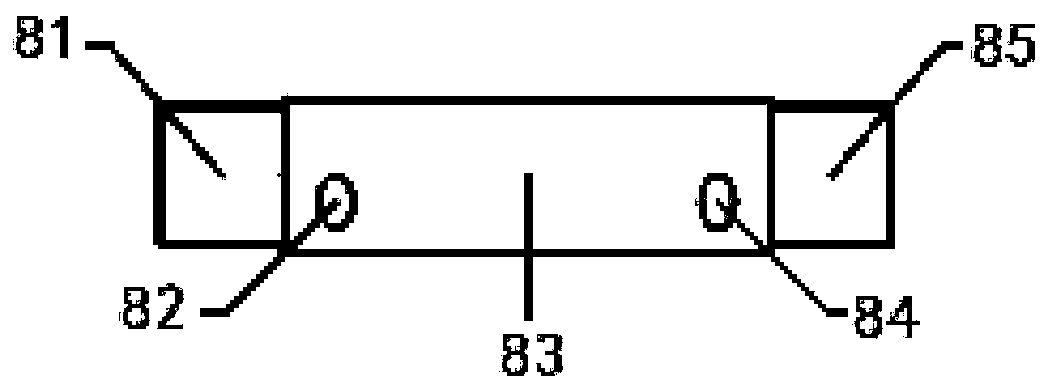

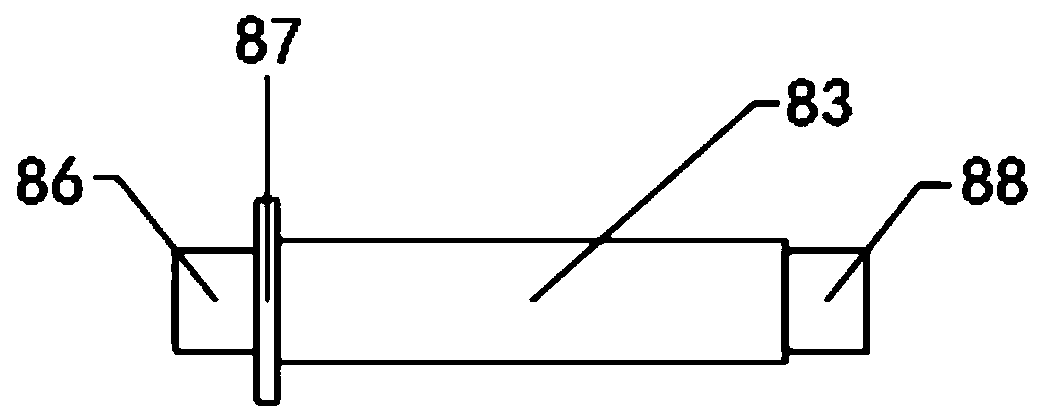

[0065] This embodiment relates to a non-spectral infrared gas sensor, such as figure 1 As shown, the whole machine includes an air inlet interface 7, an alarm 1, a display 2, a gas concentration output interface 3, a main control board 4, a cable 5, a gas pipe 6, an air inlet interface 7, an air chamber 8, and an air outlet interface 9; among them, The air chamber is made up of a transmitting end 81, an air chamber shell 83 and a receiving end 85, wherein the alarm 1 is specifically an audible and visual alarm, and the display 2 is specifically an LCD display, such as Figure 2-4 shown.

[0066] The connection relationship of each component is as follows:

[0067] The transmitting end 81 is connected to one end of the air cavity shell 83, and the receiving end 85 is connected to the other end of the air cavity shell 83; wherein, the air cavity shell 83 is a hollow cylindrical structure, which is made of metal aluminum material; the air inlet port 7 and The air outlet interfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com