Self-closing valve for tube bursting

A technology for self-closing valves and bursting pipes, which is applied in safety valves, balance valves, valve devices, etc., and can solve problems such as floods, fires, and energy waste at the bursting pipe site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

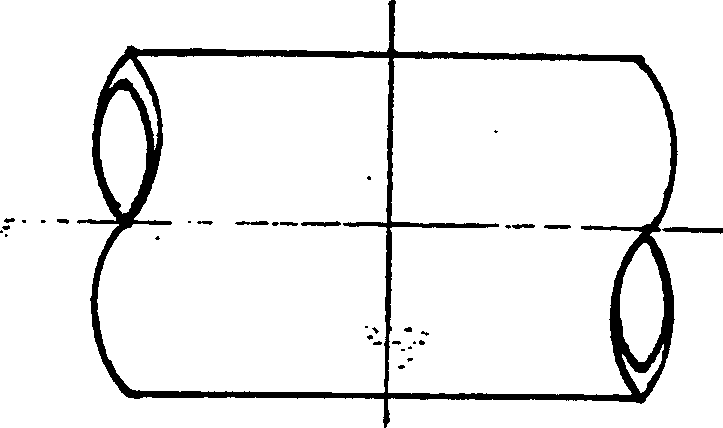

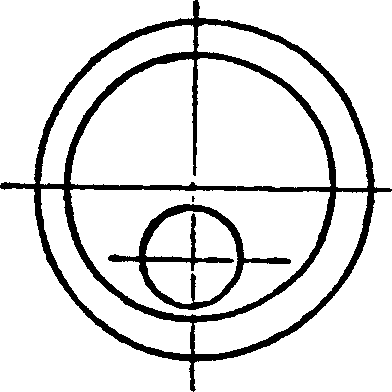

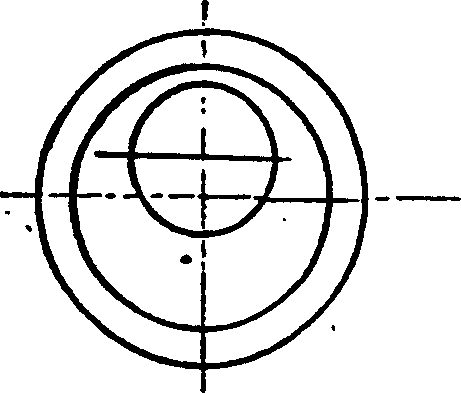

[0009] The basic principle of the squib self-closing valve of the present invention is to automatically judge and operate itself according to the comparison result of the measured flow velocity of the fluid flowing through it and the set flow velocity. The specific implementation method has multiple modes such as mechanical type and electric type. The electric type is to increase the electric detector, comparator and electric actuator on the basis of the mechanical type. What is described in the figure is a mechanical squib self-closing valve of the present invention. The valve plate has the function of measuring the flow rate and executing the closing function. The weight has the function of setting the flow rate. The set flow rate can be changed by increasing or decreasing the weight of the weight the size of. figure 1 , figure 2 , image 3 , Fig. 4 all do not indicate the connection mode of the size and the inlet and outlet pipes at both ends. This is because the pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com