Complex rotary wine/off-set rotary wine craft

A rotorcraft and composite technology, applied in the aviation field, can solve problems such as high fuel consumption, poor balance ability, and low flight safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

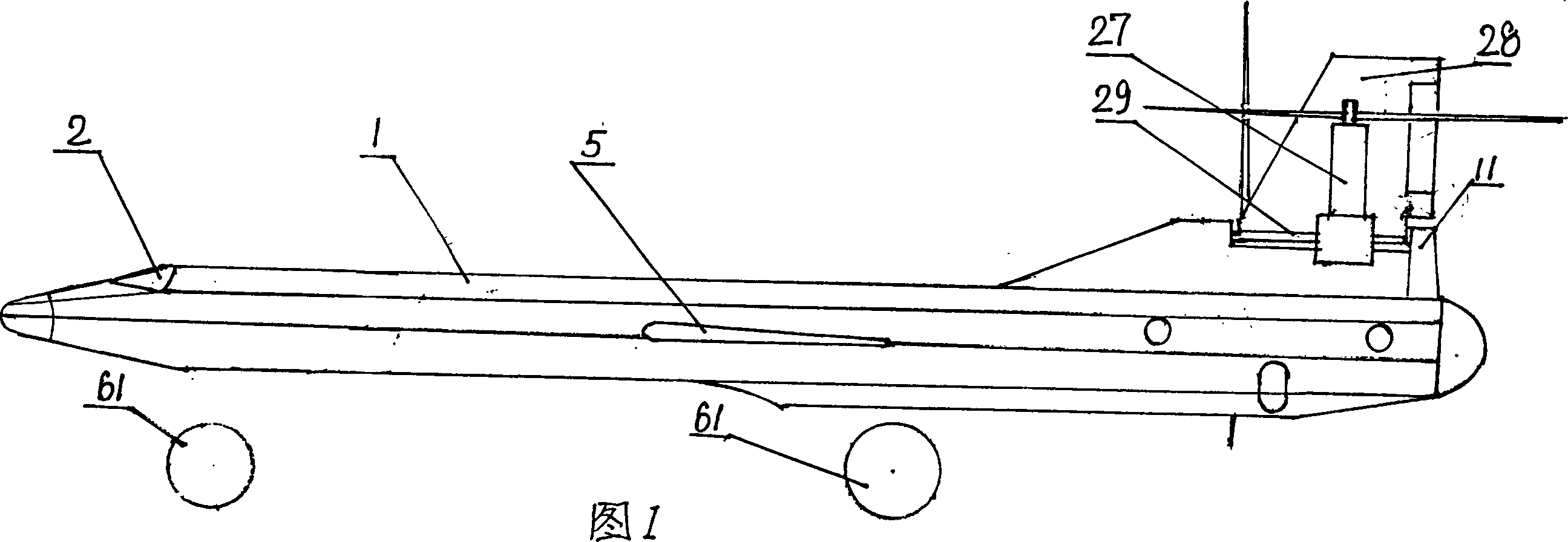

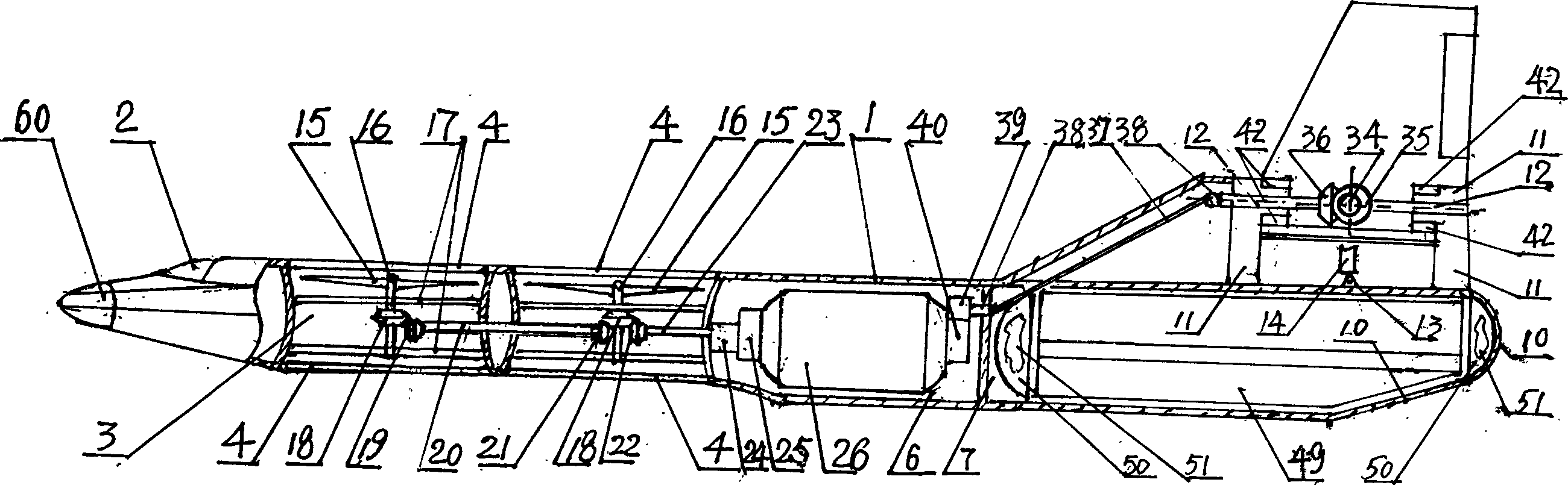

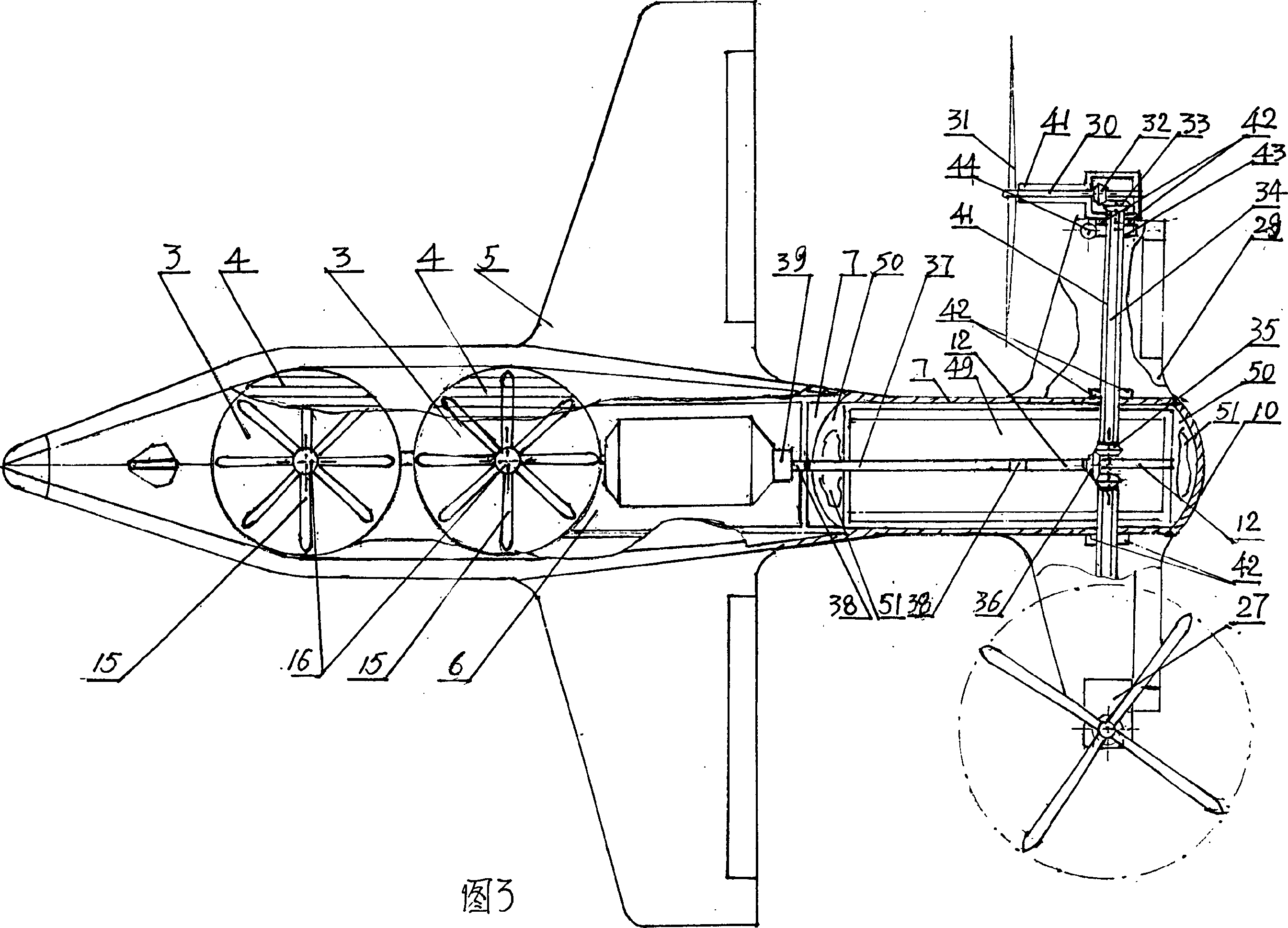

[0024] Below in conjunction with view, the present invention will be further described:

[0025] When the aircraft takes off vertically, first open the louvered hole cover 4 and start the worm 44 to drive the worm gear 43 to rotate the L-shaped shaft rotating sleeve 41 to make the eccentric rotor rotate to a horizontal position, and simultaneously control and adjust the hydraulic jack 48 so that the overall swing empennage 28 is in a horizontal position , then start the engine 26 and close the clutch 24 so that the front main transmission shaft 23 drives the main bevel gear 22 bevel gear 21 intermediate drive shaft 20 transmission bevel gear 19 bevel gear 18 drives the rotating shaft 16 to make the lift rotor / fan 15 rotate

[0026] Closed clutch 39 makes rear main drive shaft 37 drive main bevel gear 36 drive bevel gear 35 intermediate drive shaft 34 drive bevel gear 33 rotating shaft bevel gear 32 rotating shaft 30 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com