Interdental brush and method of producing the same

A manufacturing method and technology of interdental brushes, which are applied to brushes, brush bodies, bristles, etc., can solve the problems of high equipment cost, complex mold structure, troublesome and other problems, and achieve the purpose of saving material cost, improving commodity quality and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

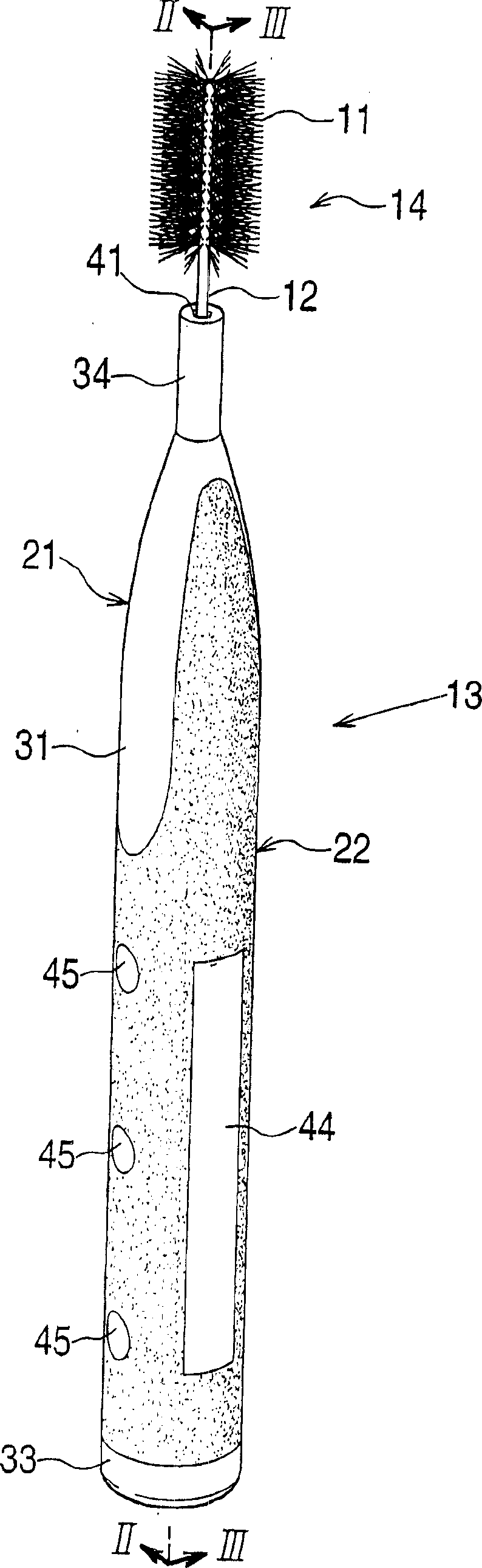

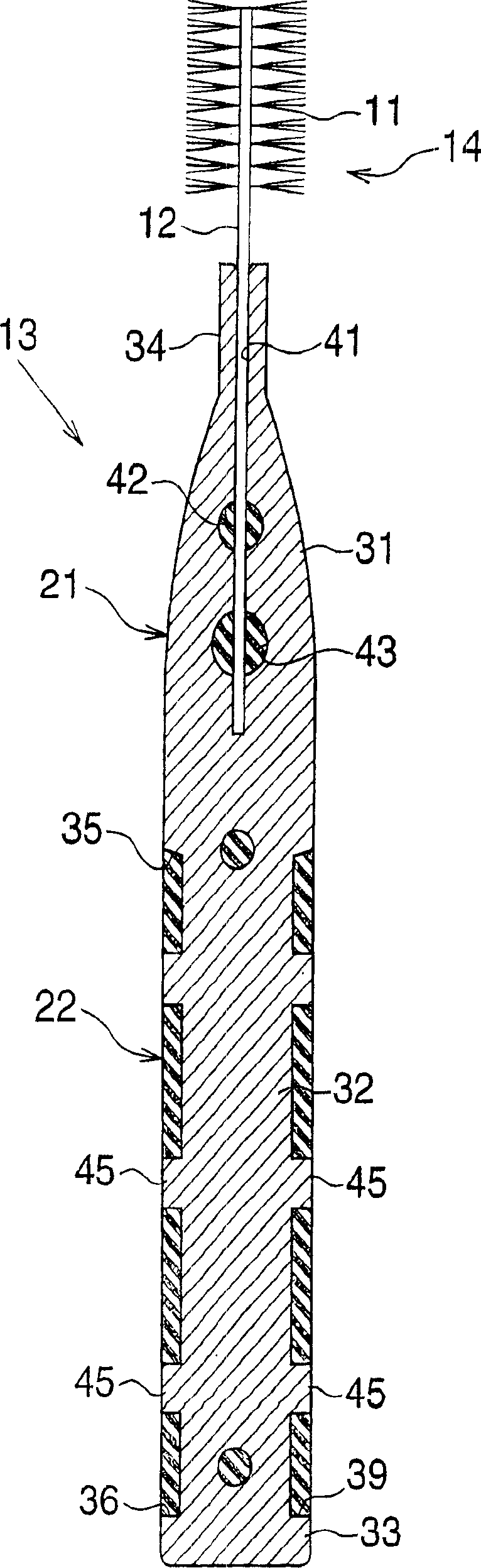

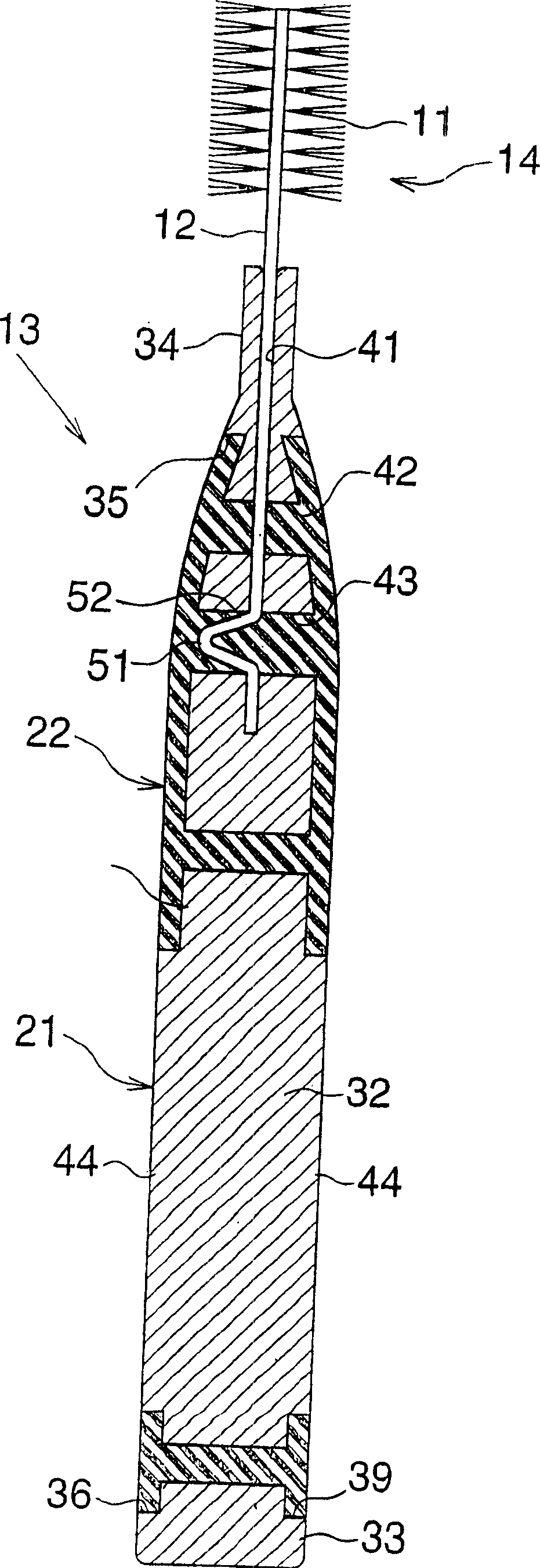

[0022] In the following explanations, the so-called inside and outside are based on Figure 1 to Figure 3 As a reference, the upper side is regarded as the inner side, and the lower side is regarded as the outer side. Furthermore, the so-called left and right are respectively represented by figure 2 The left and right sides are regarded as the left and right, the so-called up and down, respectively image 3 The left and right sides are used as up and down.

[0023] refer to Figure 1 to Figure 3 , The interdental brush is made of nylon bristles 11, stainless steel wire 12 and handle 13 made of thermoplastic synthetic resin.

[0024] The bristles 11 are divided into bundles. Each bundle of bristles 11 is sandwiched between the folded metal wires 12, and then the metal wires 12 are twisted. Thereby, a bristled strand and wire 14 having a front end portion implanted with bristles 11 and a base portion free of bristles 11 is formed.

[0025] The handle 13 is composed of a m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap