Air-cushioned operation platform

A workbench and workbench technology, which is applied to workbenches, manufacturing tools, etc., can solve the problems of large friction between the workpiece and the workbench, and achieve the effect of avoiding damage and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

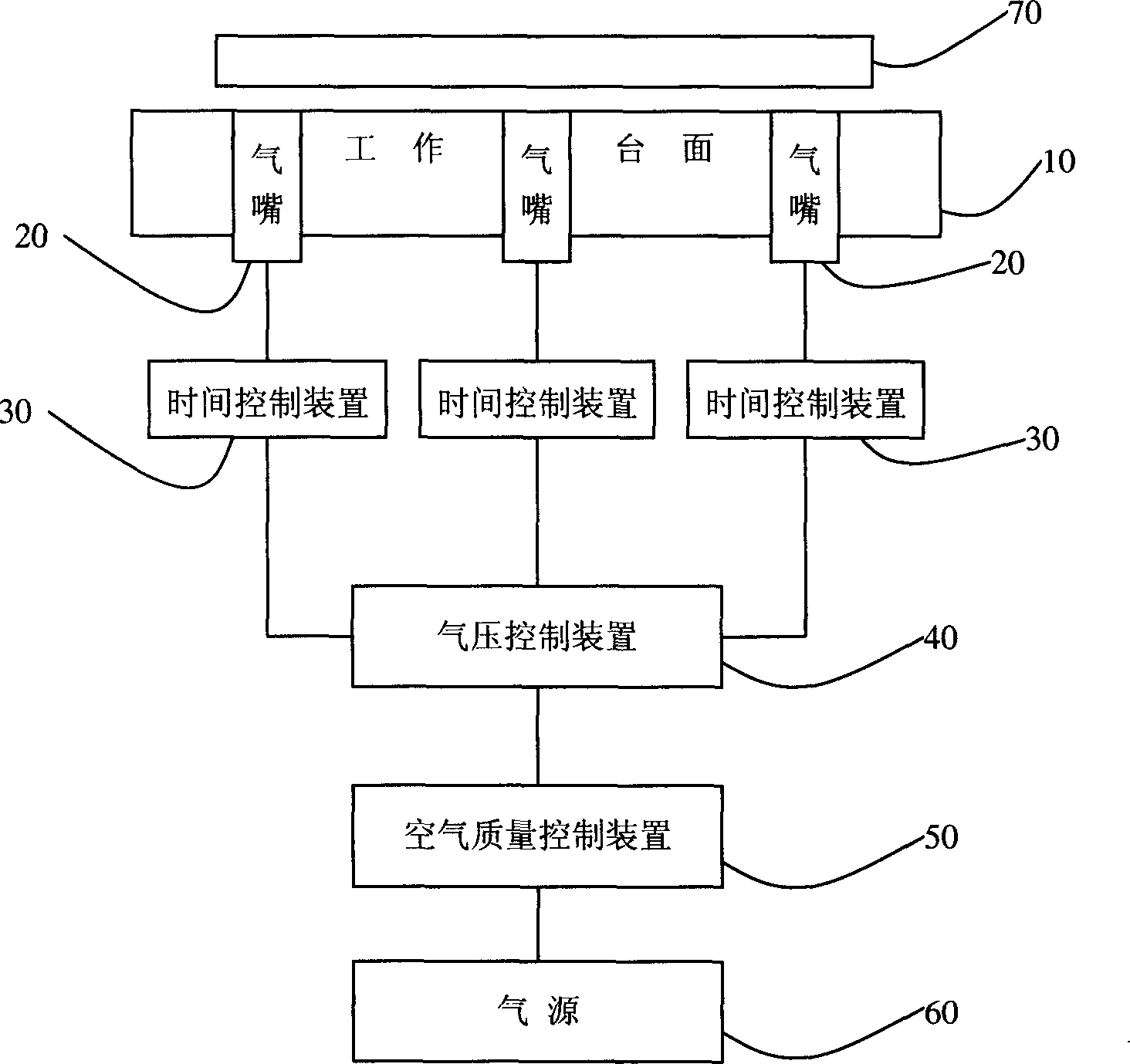

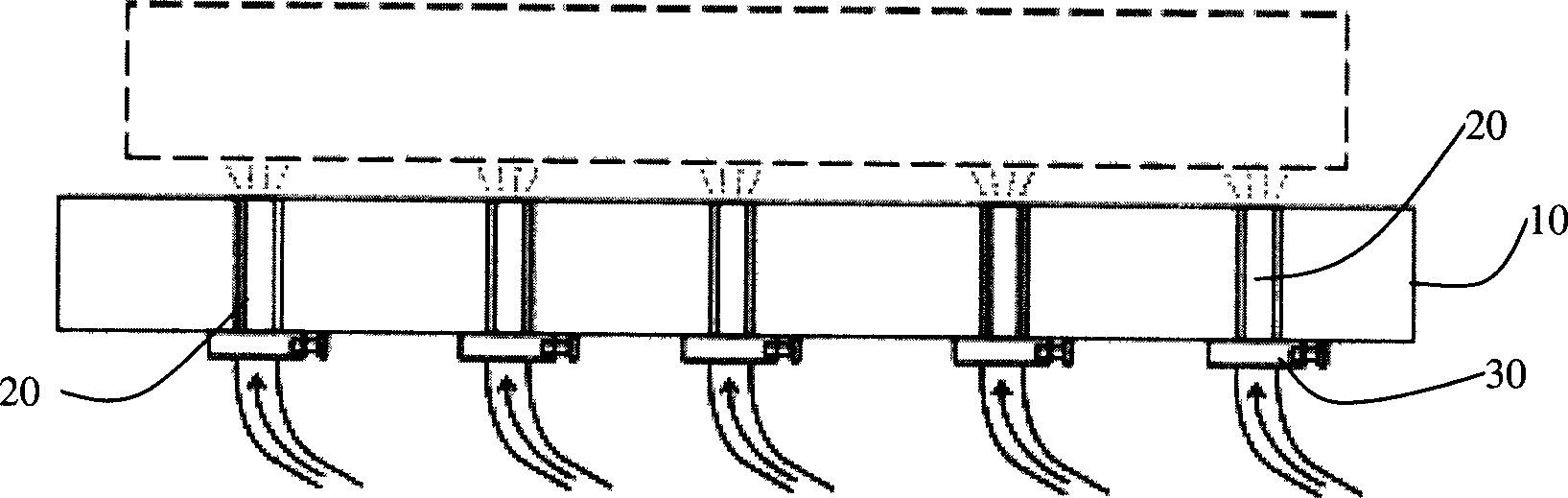

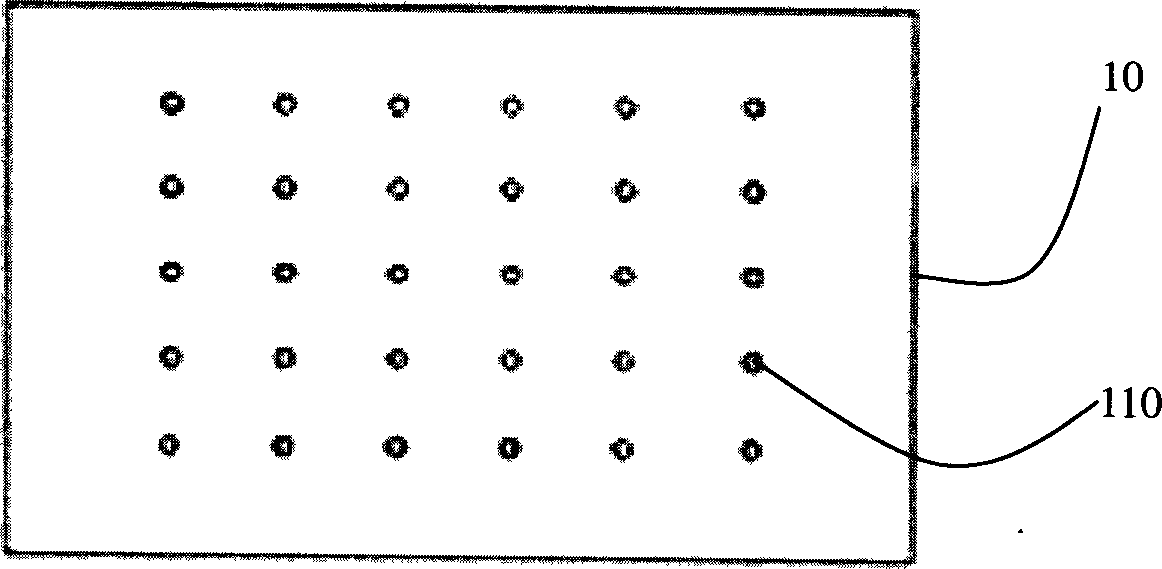

[0010] Such as figure 1 Shown is a structural principle diagram of an air cushion workbench of the present invention. This air cushion workbench comprises a working surface 10, and a plurality of air nozzles 20 connected in sequence, a plurality of time control devices 30, an air pressure control device 40, an air quality control device 50 and an air source 60, and the above-mentioned parts are connected with The tube realizes the connection between two of them.

[0011] The air quality control device 50 is connected with an air source 60, which is used to control the quality of the air to ensure the safety of the working environment.

[0012] The air pressure control device 40 is connected with the air quality control device 50 through a connecting pipe, which is used to adjust the air pressure. The air pressure control device 40 is provided with a plurality of air outlets that can be connected with the time control device 30 .

[0013] Each of the air nozzles 20 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com