Production of resin membrane

A manufacturing method and technology of resin film, applied in the field of resin, can solve the problems of discoloration of coloring material, influence of resin film quality, and failure to achieve the expected bright effect of color, so as to achieve the best vividness and ensure that the color does not change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

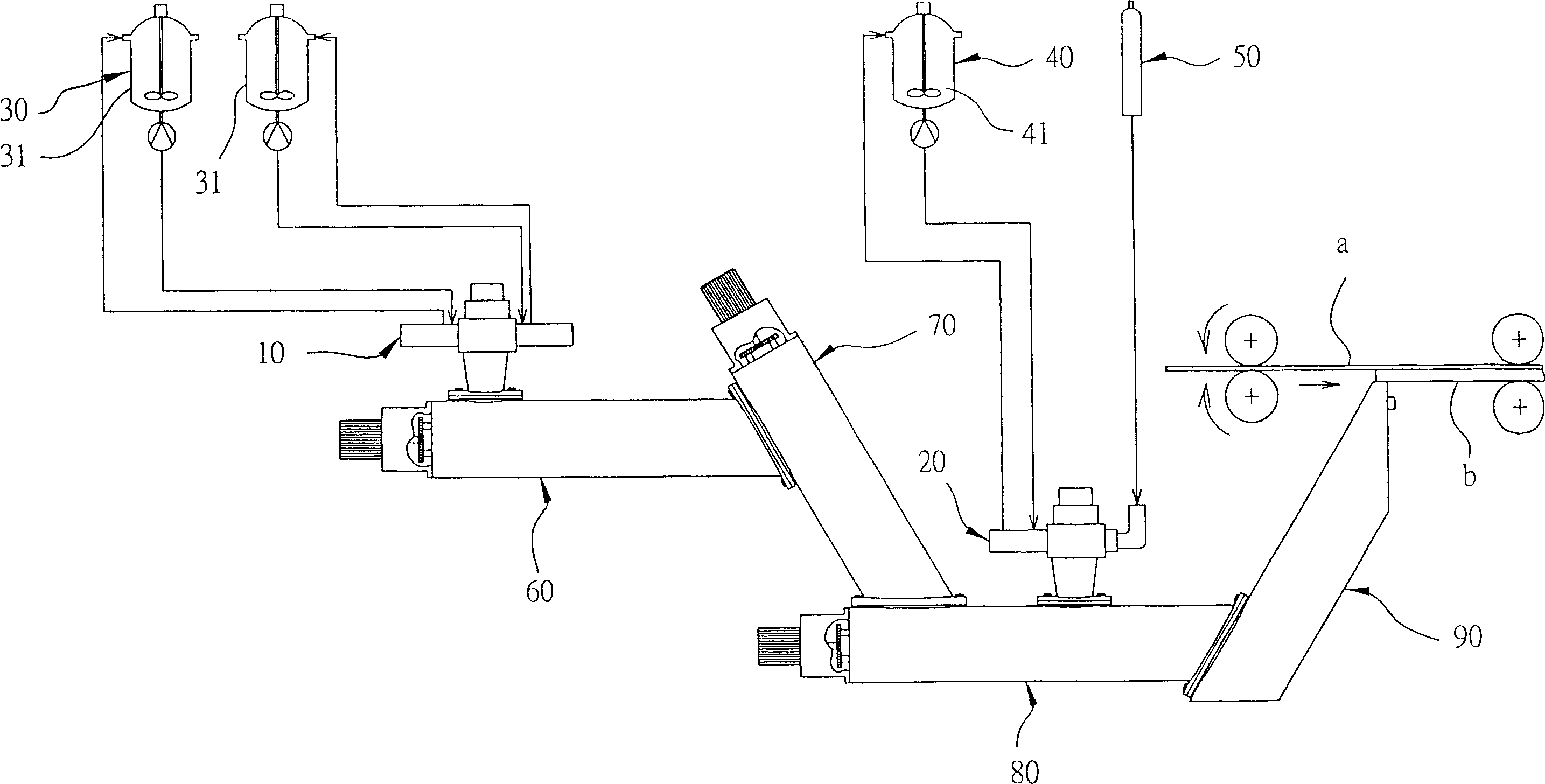

[0026] First, see figure 1 , a preferred embodiment of the method for manufacturing a resin film of the present invention mainly includes the following steps:

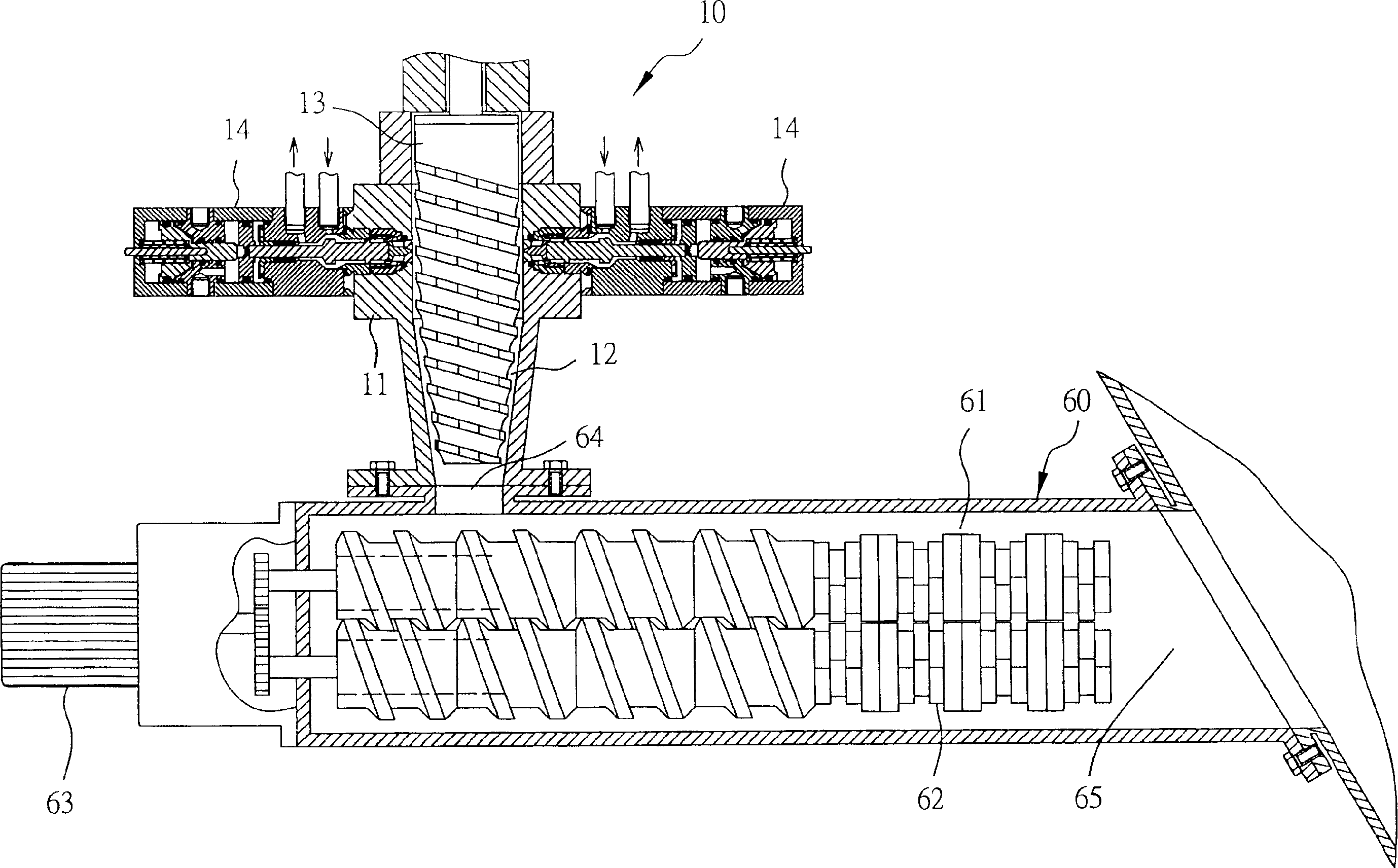

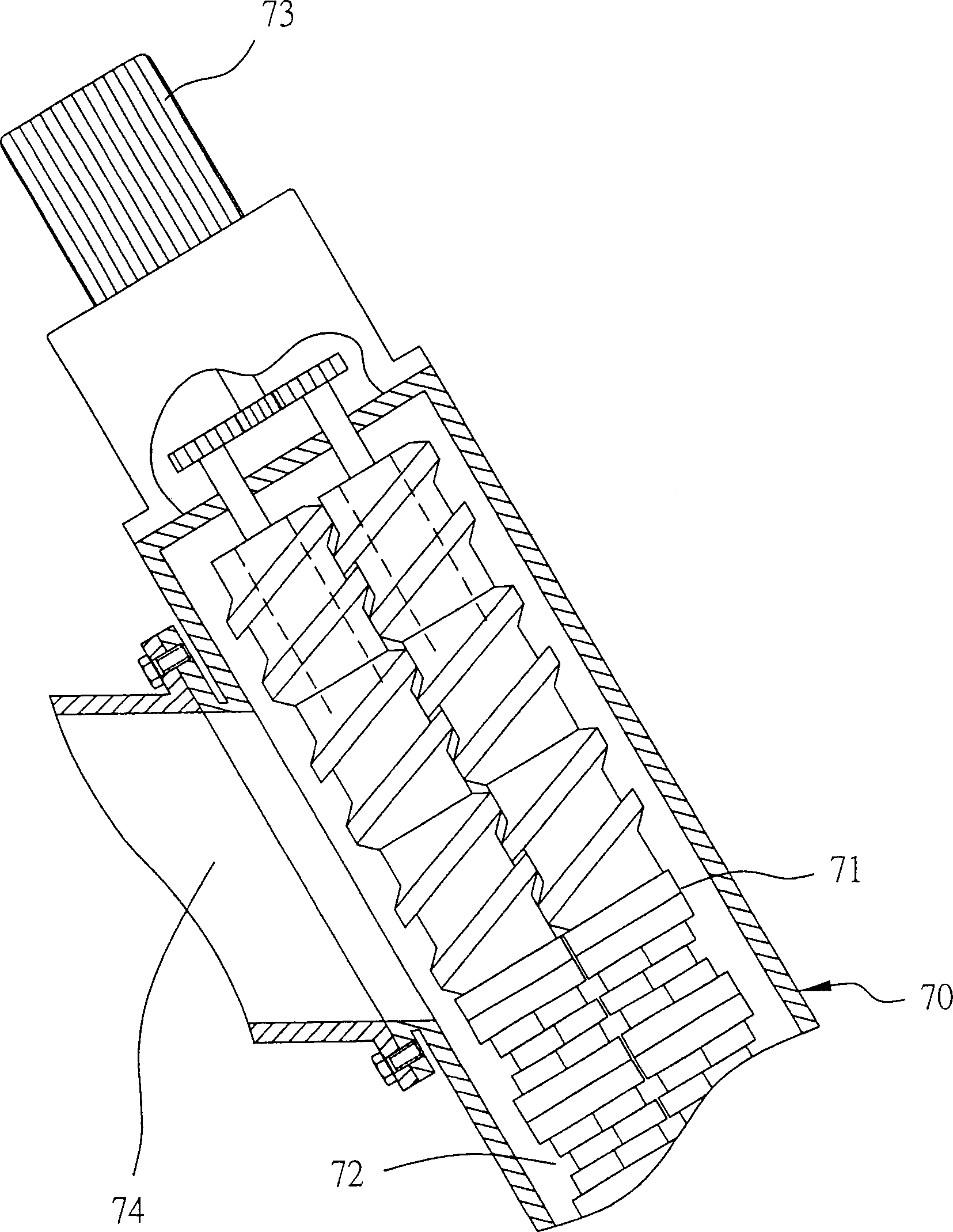

[0027] a, first inject an NCO-containing isocyanate polymer-abbreviated as PU resin and an OH-containing hydroxyl compound two liquid raw materials into a first injection mixing device 10 for preliminary mixing, and mix a colorant with a The foaming agent is injected into a second injection mixing device 20 for preliminary mixing; please refer to figure 2 , image 3 , wherein, the isocyanate polymer and hydroxyl compound are respectively filled in the barrel 31 of a metering output device 30, and are properly connected with the first shot mixing device 10, and the coloring material is also filled in a metering In the bucket 41 of the output device 40, the foaming agent is filled in a foaming device 50, and is properly connected to the second shot mixing device 20 together with the metering output device 40 of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com