Obverse-face sealing assembly of drier

A technology for sealing components and dryers, used in household dryers, washing devices, textiles and papermaking, etc., can solve problems such as external leakage and condensate leakage, and achieve the effect of preventing air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

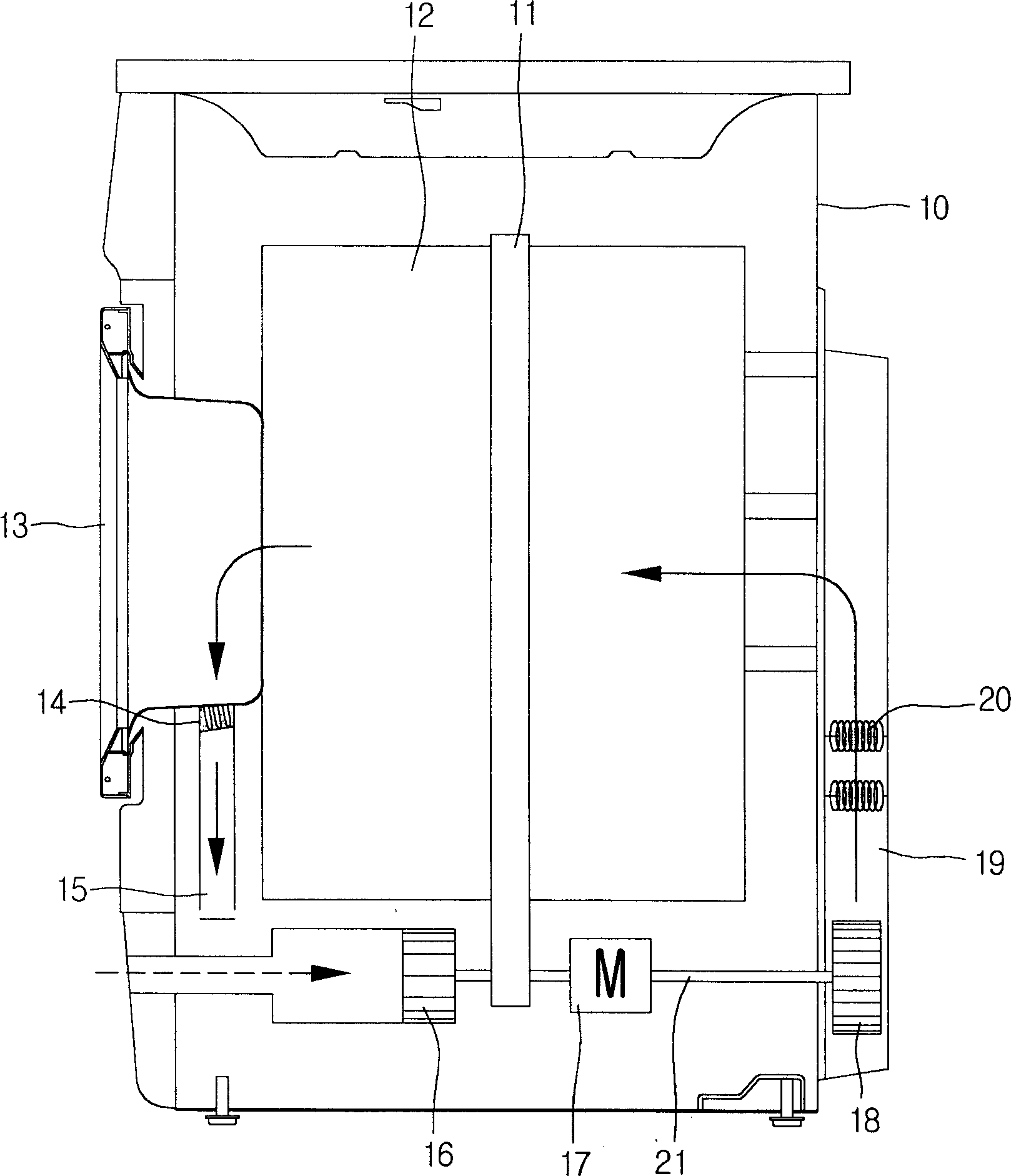

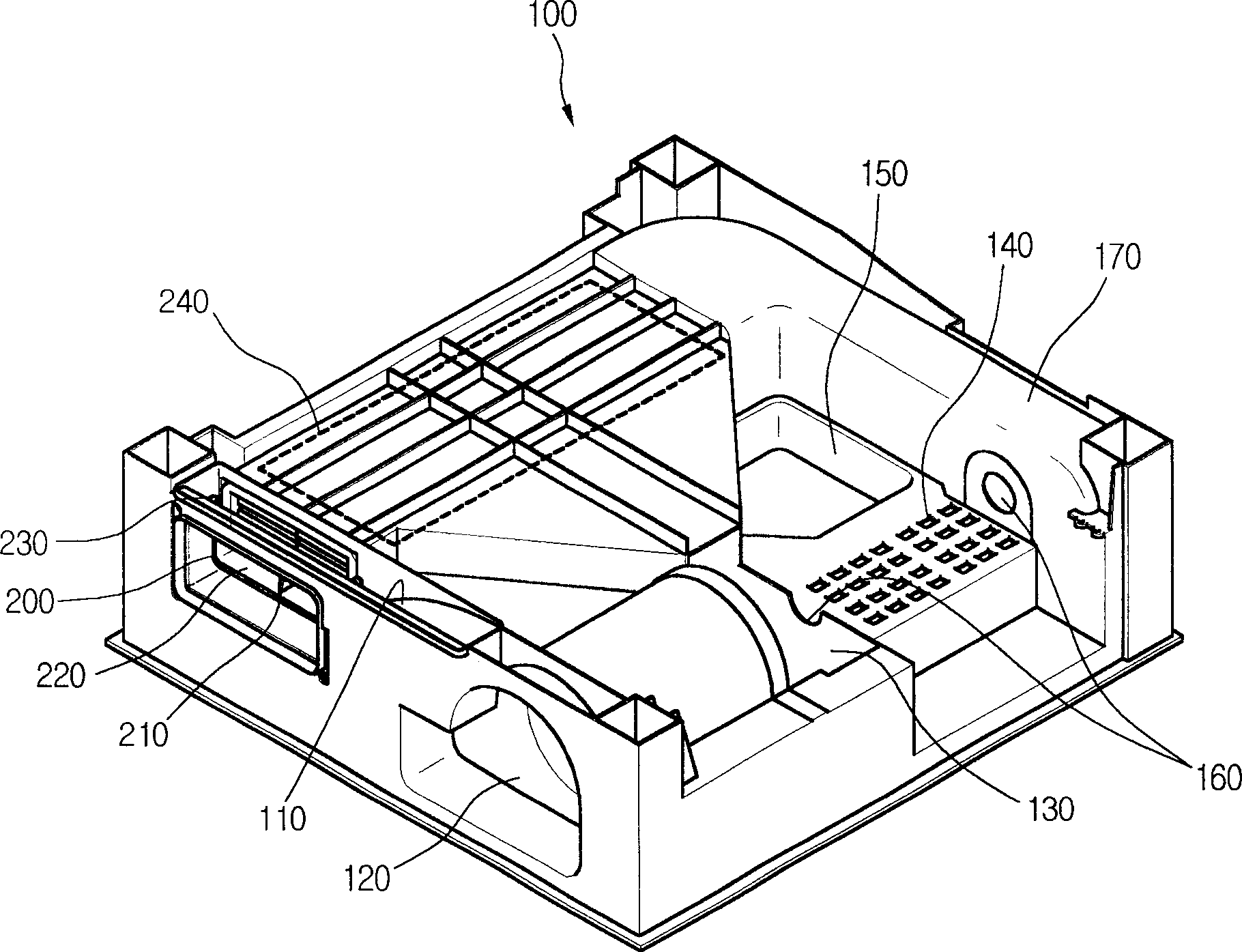

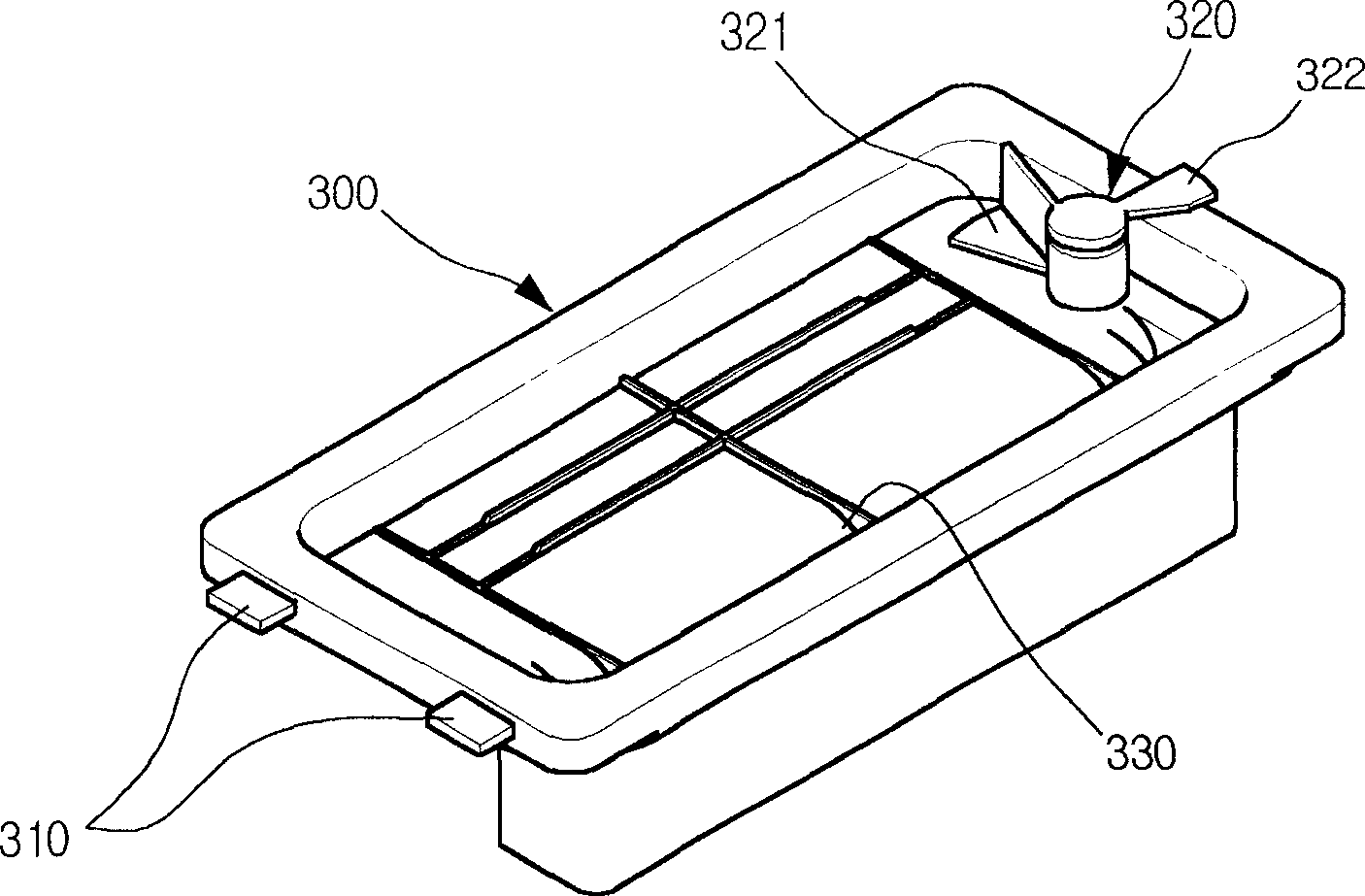

[0035] Such as figure 2As shown, the dryer chassis 100 on the front seal assembly provided by the present invention has a circulating air descending part 110 , a condenser mounting part 240 and a circulating air passage 170 . The circulating air descending part 110 may make the air passing through the inside of the drum flow into the condenser 200 through a cotton filter not shown in the figure. The condenser installation part 240 is used to install the condenser 200 . The circulation air passage 170 is a passage for the circulation air passing through the condenser 200 to flow into the drum again. In addition, the chassis 100 of the dryer also has an indoor air inlet 120 , a cooling fan installation slot 130 and a motor cooling slot 140 . The indoor air suction port 120 is used to suck indoor air capable of crossing and exchanging heat with circulating air in the condenser 200 . The cooling fan installation groove 130 is used for installing a cooling fan not shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com